Method for exploiting thick-layer oil deposit in combustion of oil in situ

A technology of burning oil layers and oil layers, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of hidden dangers in production safety, difficulty in ground operation, and low recovery rate, so as to improve oil recovery speed and save operation Cost, EOR effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

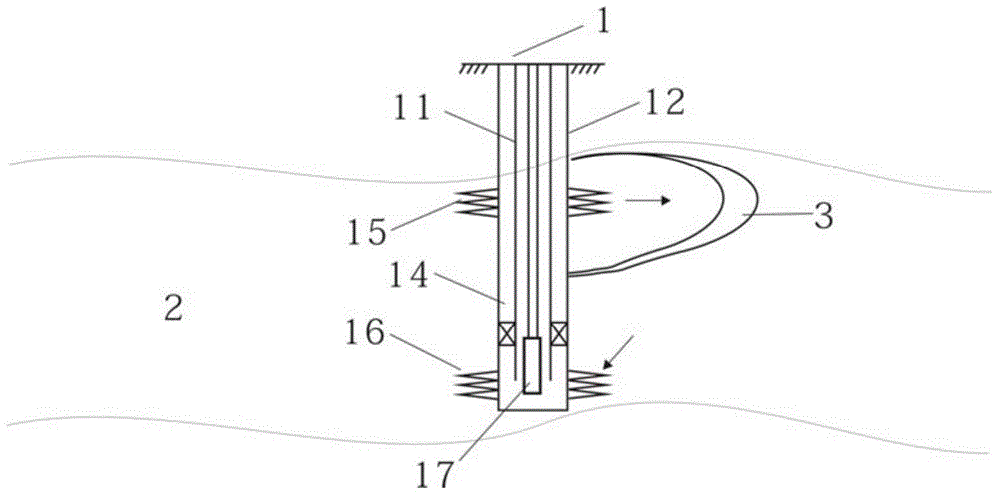

[0045] This embodiment provides a method for producing thick oil reservoirs by burning oil layers. The wellbore structure in the method is as figure 1 As shown, the continuous thickness of the target oil layer of the oil reservoir is 15 meters, and the oil reservoir has natural vertical fractures. The method includes the following steps:

[0046] (1) Deploy a vertical well 1 and complete the well with casing 12 in the natural fracture area; the injection well and the production well are the same well; the casing 12 is inserted in the wellbore to the bottom of the target reservoir 2 and the well is completed. The oil pipe 11 is lowered into the tube 12 to the bottom of the target oil layer 2, and the high-temperature ceramic packer 14 is placed empty in the oil sleeve between the oil pipe 11 and the casing 12. The high-temperature ceramic packer 14 is located at the bottom of the target oil layer 2 Above 2 meters; perform segmental perforation completion on the upper and lower casi...

Embodiment 2

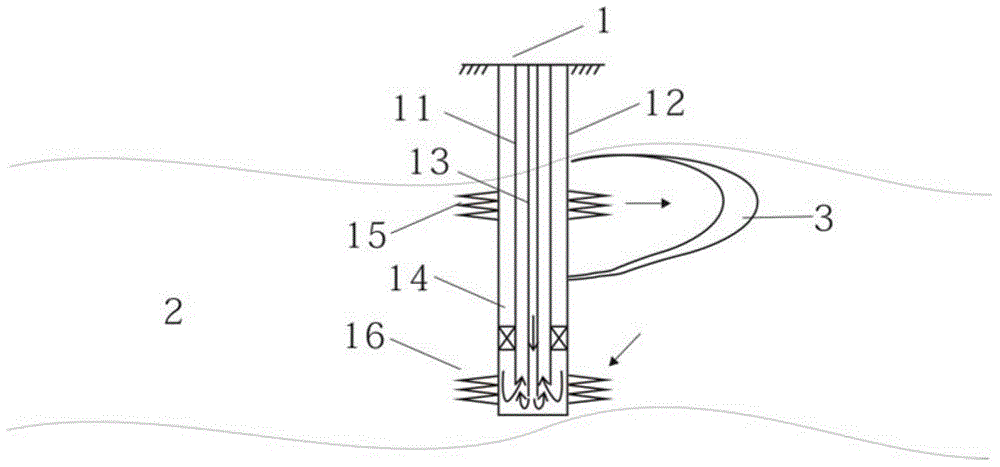

[0055] This embodiment provides a method for producing thick oil reservoirs by burning oil layers. The wellbore structure in the method is as figure 2 As shown, the target reservoir has a continuous thickness of 25 meters and no natural vertical fractures are developed in the reservoir. The method includes the following steps:

[0056] (1) Deploy a vertical well 1 and complete the well with casing 12; the injection well and the production well are both the same well; the casing 12 is run in the wellbore to the bottom of the target reservoir 2 and the well is completed, and the casing 12 is run Enter the oil pipe 11 to the bottom boundary of the target oil layer 2, and place a high temperature resistant ceramic packer 14 vacant in the oil sleeve between the oil pipe 11 and the casing 12. The high temperature resistant ceramic packer 14 is located 3 meters above the bottom boundary of the target oil layer 2; Perform segmental perforation completion on the upper and lower casing 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com