Garbage separation and filtration treatment equipment

A technology for separation, filtration and treatment equipment, which is applied in the direction of solid separation, separating solids from solids with airflow, road cleaning, etc. Secondary pollution, the effect of solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

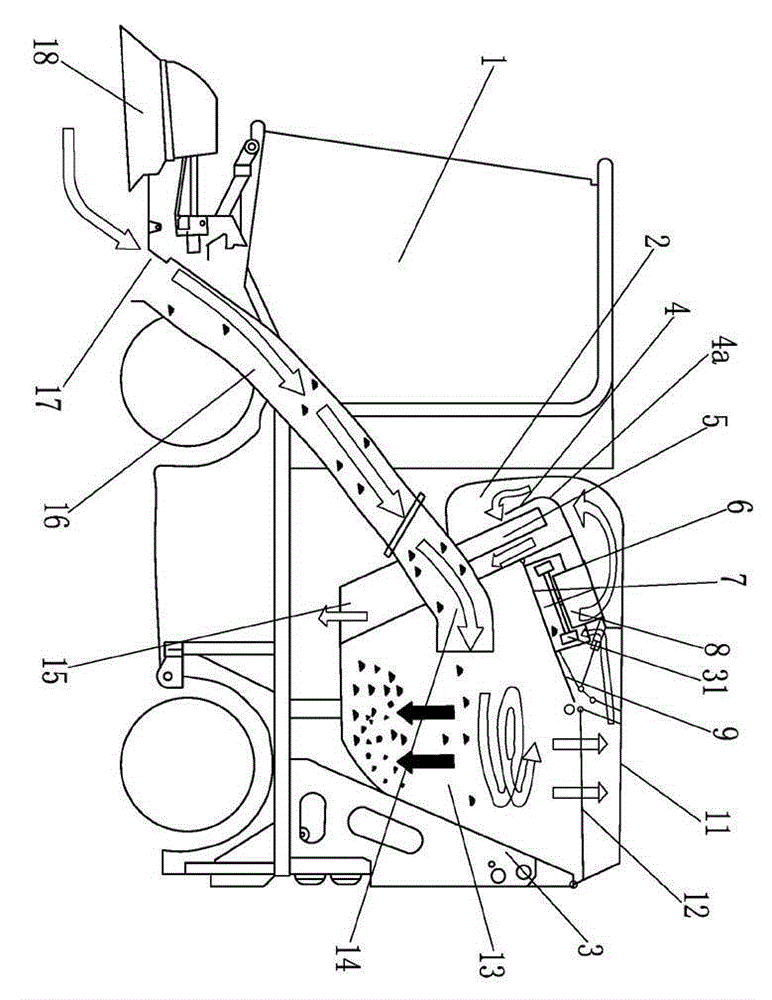

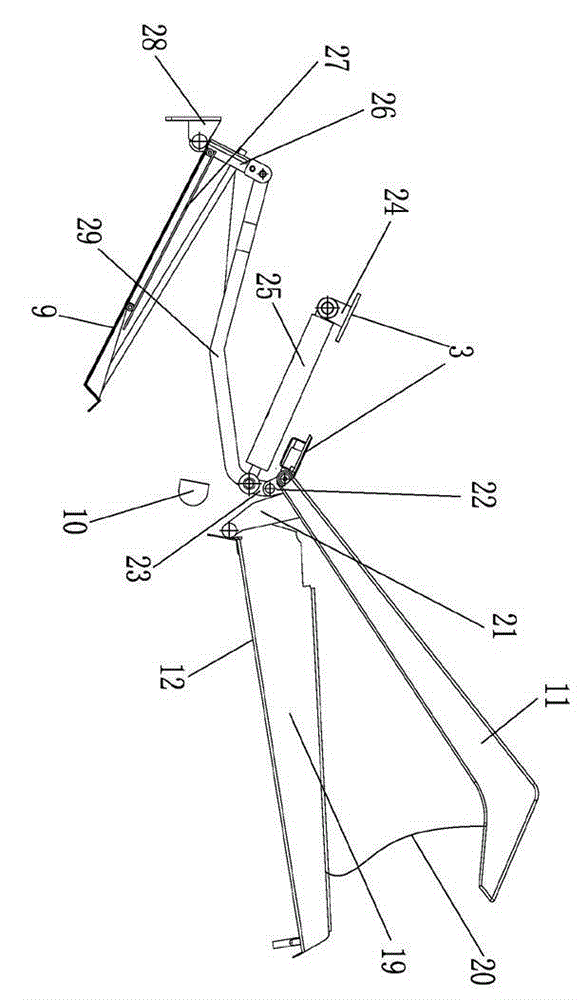

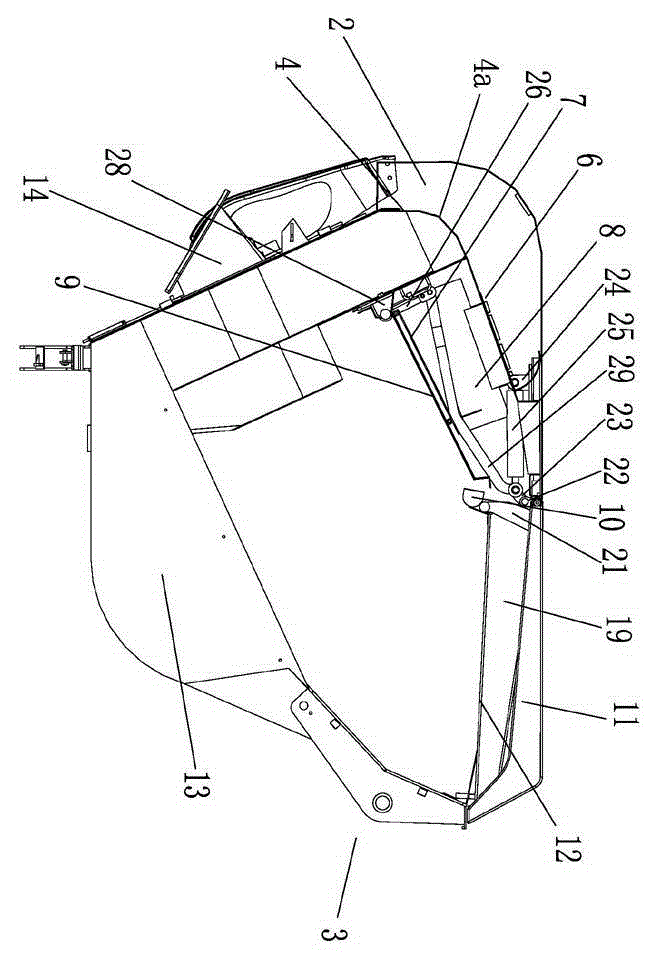

[0027] Such as Figure 1-5 As shown, a garbage separation and filtering treatment equipment includes a garbage bin 3 installed behind the cab 1, a suction device directly used for sucking garbage, and the suction end of the suction device faces the working area of the cleaning brush 18, The discharge end of the suction device is connected to the garbage bin 3. The garbage bin 3 is also provided with a suction fan 5 that can cause negative pressure in the garbage bin 3. The garbage bin 3 includes a receiving chamber 13 and an exhaust chamber 2, and the exhaust chamber 2 is in the holding chamber. The air outlet side of the material chamber 13 is opposite to the material pouring side of the material chamber 13, and the material chamber 13 directly communicates with the discharge end of the suction device.

[0028] The air outlet side and the material dumping side of the material receiving chamber 13 are both slope structures and present a trumpet shape with a large upper end and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com