Elastic broom with adjustable elastic force

An elastic and elastic technology, used in road cleaning, construction, cleaning methods, etc., can solve the problems of rapid bristle wear and consumption, bristle wear, waste and other problems, to save costs, prolong service life, and slow down wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

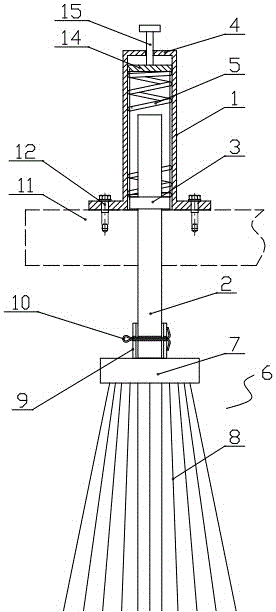

[0020] like figure 1 As shown, an elastic broom with adjustable elastic force comprises a cylinder body 1, a piston rod 2, a piston 3, a compression spring 5, a hair brush 6, a pressure plate 14 and an adjusting bolt 15, and the cylinder body is arranged in an inverted manner, namely The opening of the cylinder body faces downward; a threaded hole is opened on the rear wall of the cylinder body, and the adjusting bolt is passed through the threaded hole, and the lower end of the adjusting bolt is pushed against the pressure plate, and the pressure plate is located on the Cylinder cavity; the piston 3 is arranged on the piston rod 2, the compression spring 5 is arranged between the piston and the pressing plate, and the lower end of the piston rod is detachably connected with a brush 6. The brush 6 includes a base plate 7 and bristles 8, and the bristles are fixed on the base plate. A cylindrical socket 9 is arranged on the base plate.

[0021] like figure 1 As shown, in ord...

Embodiment 2

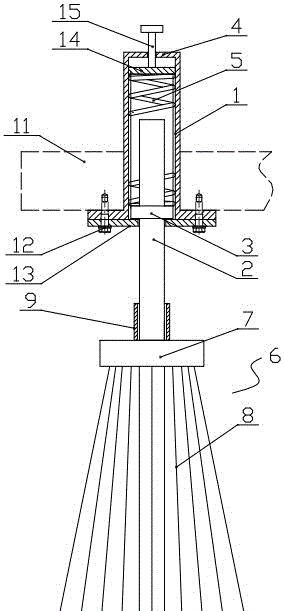

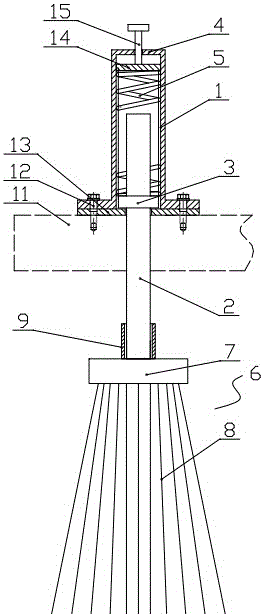

[0026] like figure 2 and image 3 As shown, an elastic broom with adjustable elastic force includes a cylinder body 1, a piston rod 2, a piston 3, a compression spring 5, a brush 6, a pressure plate 14 and an adjusting bolt 15, and the cylinder body 1 is arranged in an upside-down manner. That is, the opening of the cylinder body 1 faces downward; a threaded hole is provided on the rear wall of the cylinder body 1, and the adjusting bolt 15 is passed through the threaded hole, and the lower end of the adjusting bolt 15 is pressed against the pressure plate 14 Above, the pressure plate 14 is located in the inner cavity of the cylinder body 1; the piston 3 is set on the piston rod 2, the pressure spring 5 is set between the piston 3 and the pressure plate 12, and the lower part of the piston rod 2 passes through the cylinder head 13, and a brush 6 is detachably connected to the lower end of the piston rod. The brush 6 includes a base plate 7 and bristles 8, and the bristles a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com