Molding for a motor vehicle for transmitting an impact force to a hood sensor

A molding part, sensor technology, applied in vehicle parts, superstructure sub-assemblies, bumpers, etc., can solve problems such as time delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

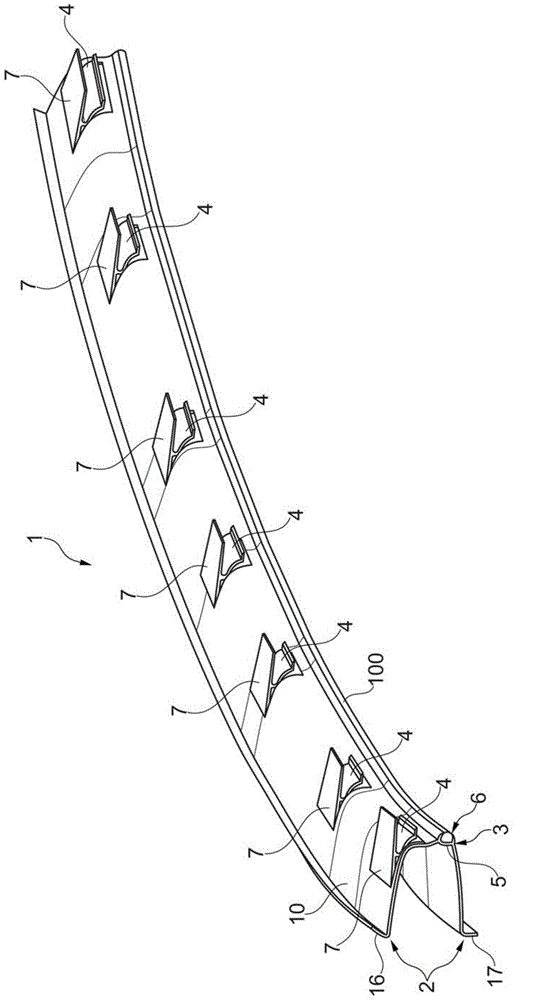

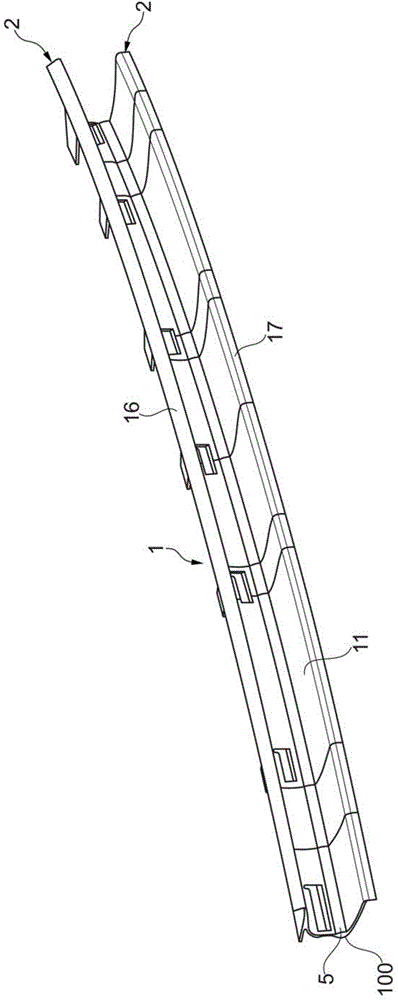

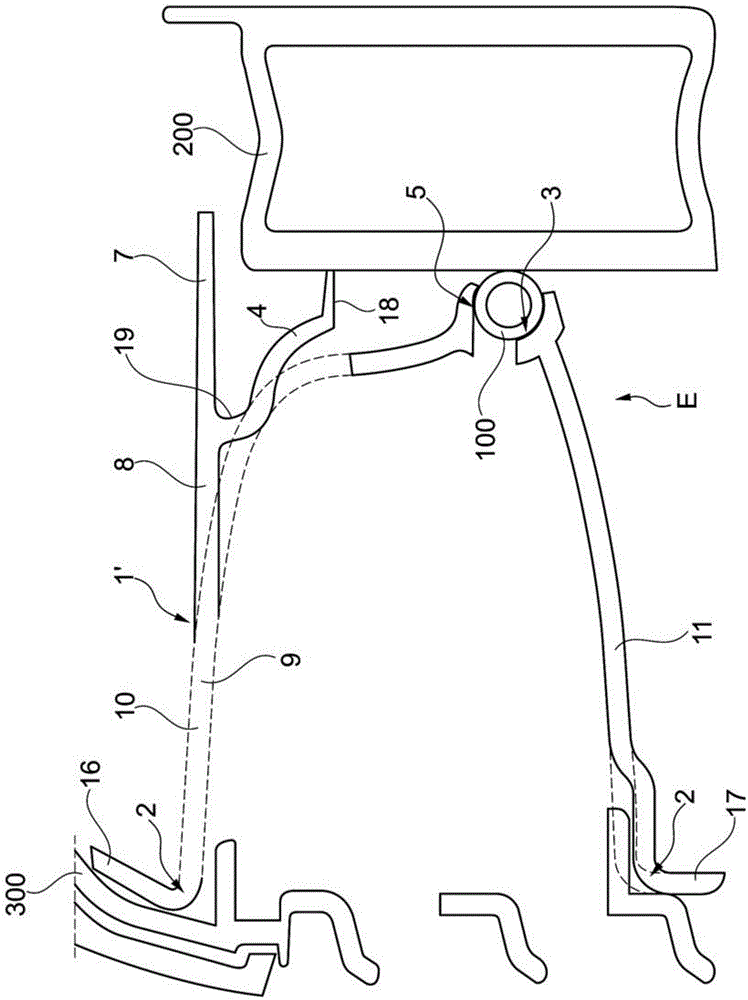

[0040] figure 1 and 2 A possible embodiment of a molded part 1 is shown schematically, which serves to transmit crash forces to a hood sensor and which can be used, for example, in a motor vehicle. figure 1 The molded part 1 is shown from a rear perspective. figure 2 The molded part 1 is shown from a frontal perspective. The molded part 1 together with the cover sensor 100 forms a structural unit, wherein the cover sensor 100 is connected to the molded part 1 .

[0041] The molded part 1 has a receiving region 2 for absorbing the impact force and a transmission section 3 for transmitting at least part of the impact force to the cover sensor 100 . The molded part 1 is, for example, an injection-molded plastic part.

[0042] The profiled part 1 is preferably designed as an elongated profile with an approximately C-shaped cross section, the receiving area 2 being arranged at the open end of the profile and the transmission section 3 being arranged at the other end of the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com