Glass lamination fitting equipment

A technology for laminating equipment and glass, applied in the direction of lamination, lamination device, layered products, etc., can solve the problems of easily damaged glass and no lamination lamination equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] A specific example is provided below to illustrate the mechanism of the glass lamination and bonding equipment proposed by the present invention.

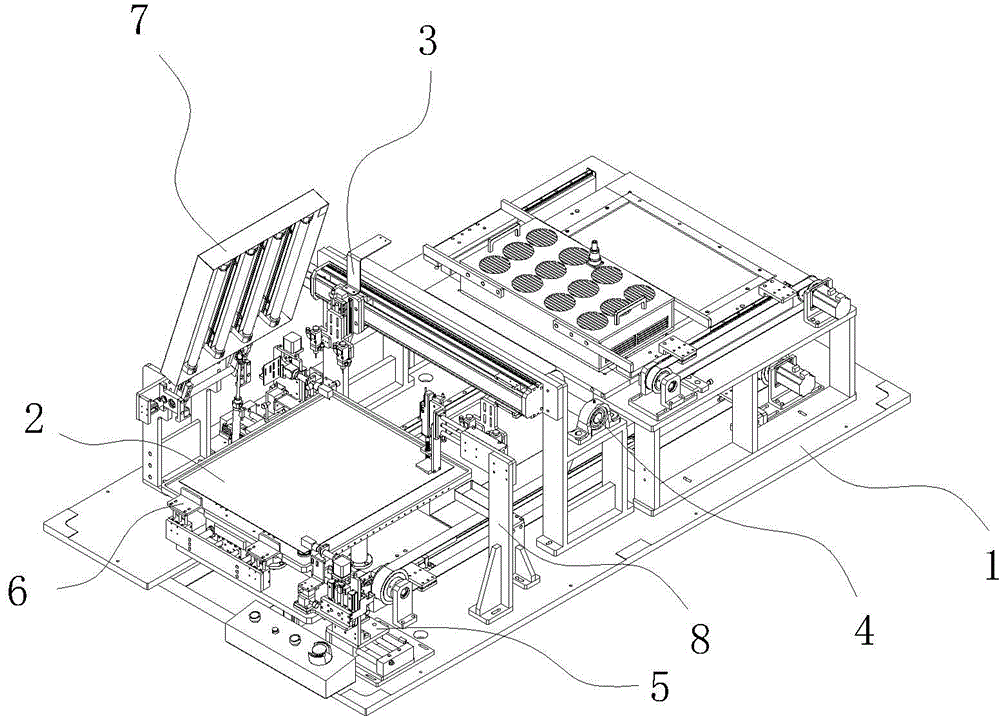

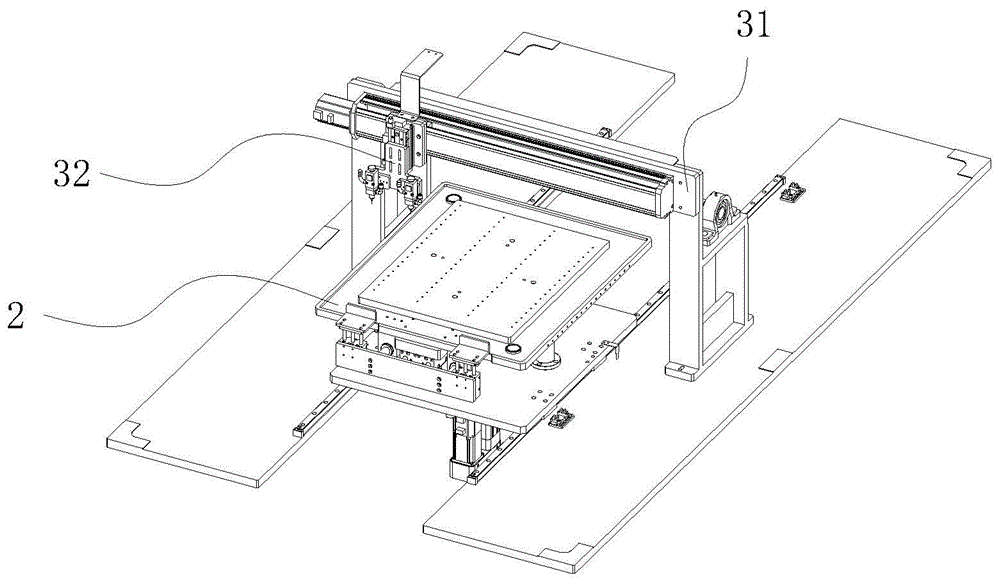

[0046] refer to figure 1 , a preferred embodiment of the glass lamination bonding equipment proposed by the present invention includes a base 1, and a loading platform 2 installed on the base 1, a dispensing mechanism 3, a bonding mechanism 4, an image taking mechanism 5, a calibration Mechanism 6 and curing mechanism 7.

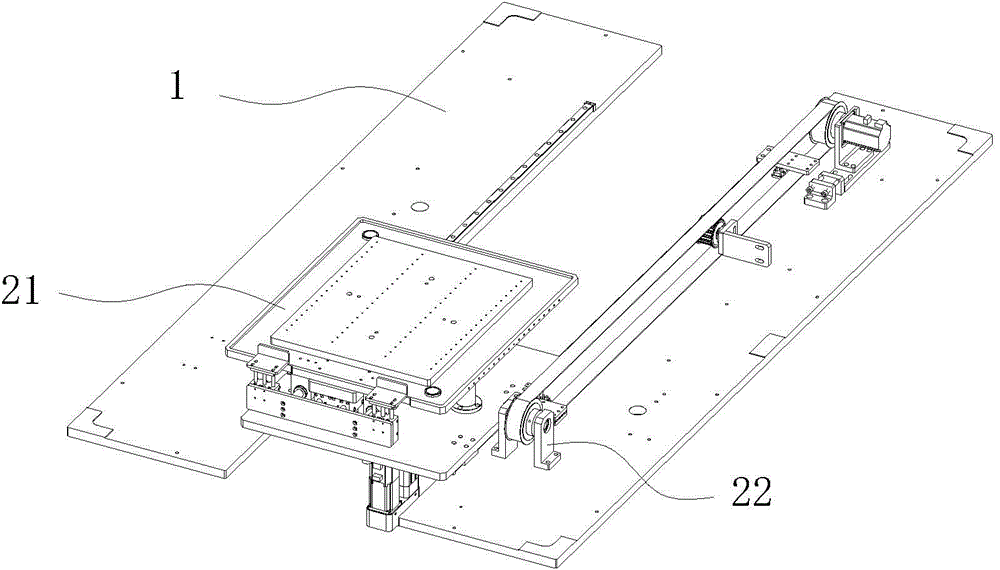

[0047] see figure 2 . The loading platform 2 is used for carrying glass, and specifically includes an installation platform 21 and a moving device 22 . The installation platform 21 is a vacuum adsorption platform, and the glass to be bonded is placed on the installation platform 21. A moving device 22 is arranged under the installation platform 21. The moving device 22 is composed of a horizontal moving device 221 and a lifting moving device 222. The horizontal moving device 221 includes two groups of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com