High-barrier bi-directionally stretched polythene film and preparation method thereof

A technology of polyethylene film and biaxial stretching, which is applied in the direction of chemical instruments and methods, flat products, and other household appliances, can solve the problem of difficult to improve the gas barrier performance of biaxially stretched polyethylene film, and the difficulty of matching the temperature of biaxial stretching process. Stretch and other issues, to achieve the effect of excellent barrier properties and mechanical properties, low cost, high mechanical strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

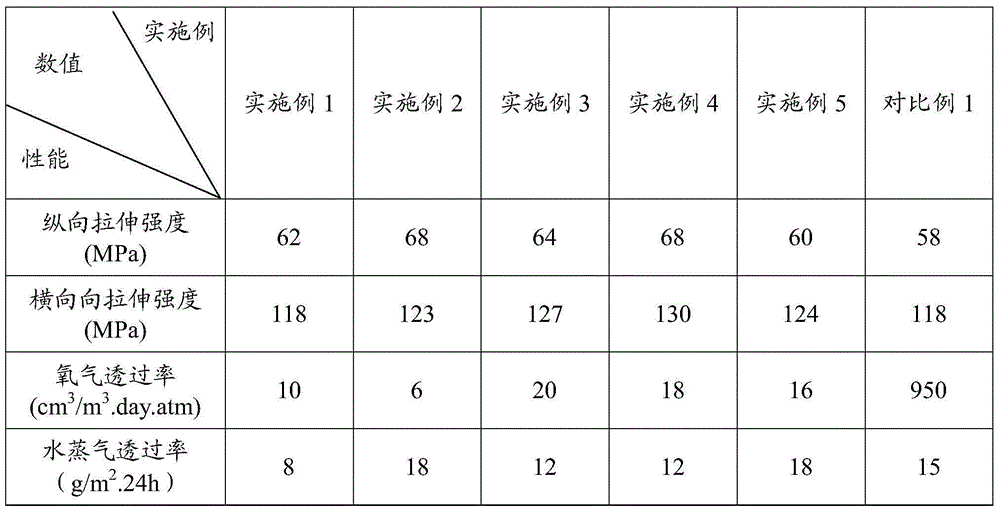

Embodiment 1

[0024] The polyethylene resin was prepared by catalytic polymerization of ethylene and 5wt% hexene with a metallocene catalyst, and its melt index (MFR) was 1.7g / 10min.

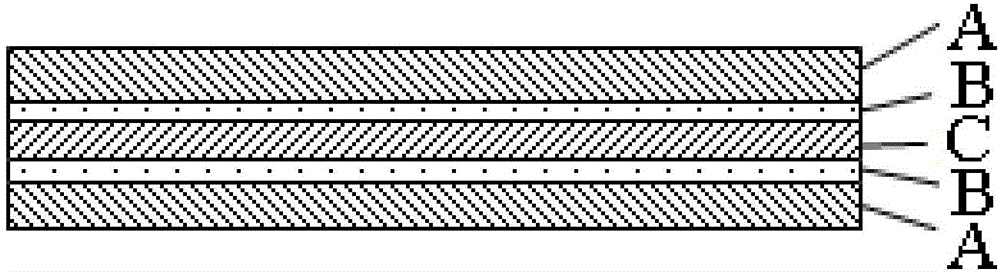

[0025] Polyethylene resin A, maleic anhydride modified polyethylene resin (maleic anhydride graft rate 0.5%) B and ethylene-vinyl alcohol copolymer resin (vinyl content is 32wt%) C are co-extruded through an extruder , meet at the five-layer die head to form a resin melt with A / B / C / B / A structure, and form a resin sheet with A / B / C / B / A structure after being cooled by a chill roll at 30°C ;Introduce the resin sheet into the longitudinal stretching device in the biaxial stretching equipment, after preheating at 120°C, stretch it 4 times under the condition of 80°C, and then enter the transverse stretching equipment, after preheating at 130°C, Stretch 8 times at 120°C, and then shape at 125°C to form a high-barrier biaxially oriented polyethylene film with A / B / C / B / A structure. The film is wound up after surface co...

Embodiment 2

[0028] The polyethylene resin was prepared by catalytic polymerization of ethylene and 6wt% hexene with a metallocene catalyst, and its melt index (MFR) was 1.5g / 10min.

[0029] Get polyethylene resin, maleic anhydride modified polyethylene resin (maleic anhydride graft rate is 2%) and ethylene-vinyl alcohol copolymer resin (vinyl content is 27wt%), wherein, add 2wt% in the polyethylene resin Anti-blocking agent, add 1wt% antistatic agent and 1wt% smooth agent in maleic anhydride modified polyethylene resin. Co-extrude polyethylene resin A, maleic anhydride-modified polyethylene resin B and ethylene-vinyl alcohol copolymer resin C through an extruder, and meet at the five-layer die to form A / B / C / B / A The resin melt of the structure is cooled by a chill roll at 35°C to form a resin sheet with a structure of A / B / C / B / A; After preheating at 80°C, it is stretched 4.5 times at 80°C, and then enters the transverse stretching equipment. After preheating at 130°C, it is stretched 9 tim...

Embodiment 3

[0032]The polyethylene resin is prepared by catalytic polymerization of ethylene and 5wt% octene with a metallocene catalyst, and its melt index (MFR) is 2.5g / 10min.

[0033] Polyethylene resin A, maleic anhydride modified polyethylene resin (maleic anhydride graft rate 1%) B and ethylene-vinyl alcohol copolymer resin (vinyl content is 48wt%) C are co-extruded through an extruder , meet at the five-layer die head to form a resin melt with A / B / C / B / A structure, and form a resin sheet with A / B / C / B / A structure after being cooled by a chill roll at 30°C ;Introduce the resin sheet into the longitudinal stretching device in the biaxial stretching equipment, after preheating at 120°C, stretch it 4.5 times at 80°C, and then enter the transverse stretching equipment, after preheating at 130°C, Stretch 9 times at 120°C, and then shape at 125°C to form a high-barrier biaxially oriented polyethylene film with A / B / C / B / A structure. The film is wound up after surface corona treatment, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com