Vibration method for pre-tensioning prefabricated track boards

A track plate, pre-tensioning method, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of air holes, sticky skin, and excessively thick laitance on the track plate, and achieve the effect of eliminating local segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

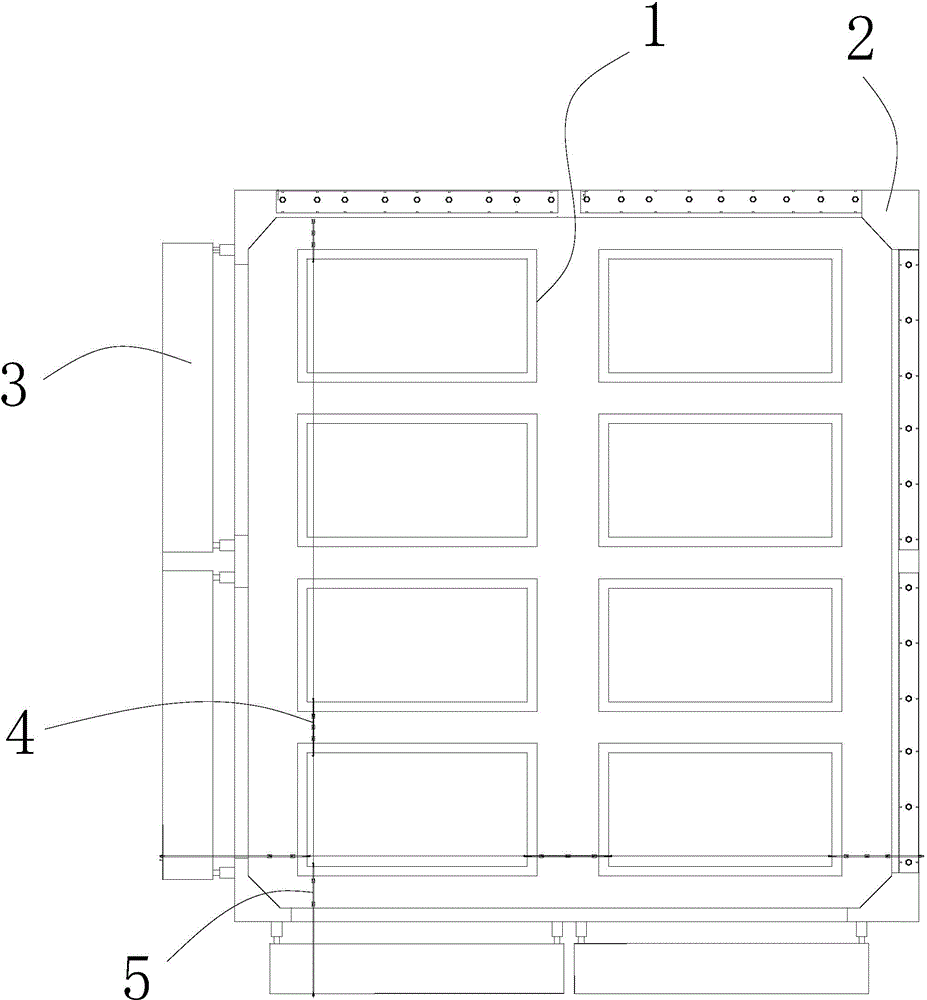

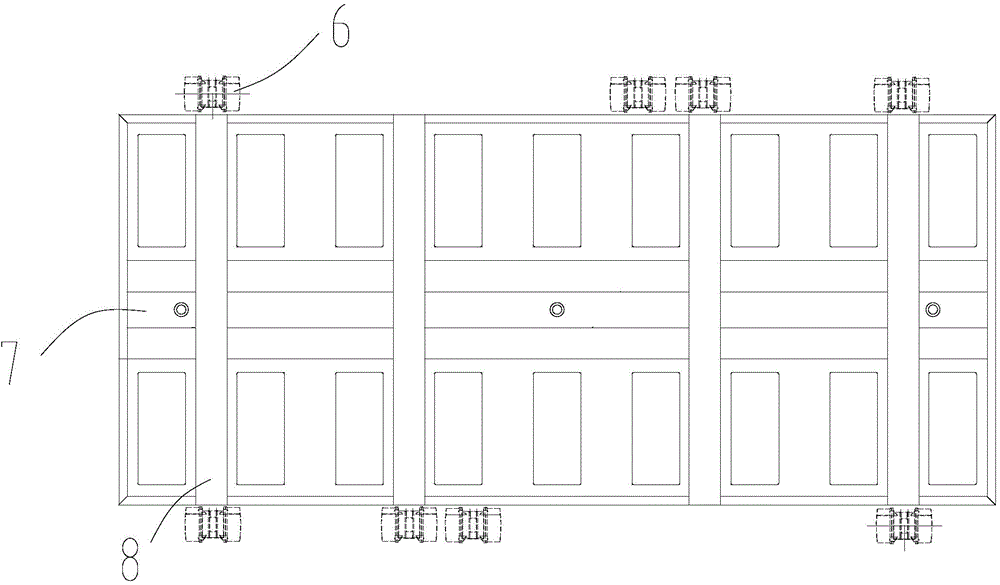

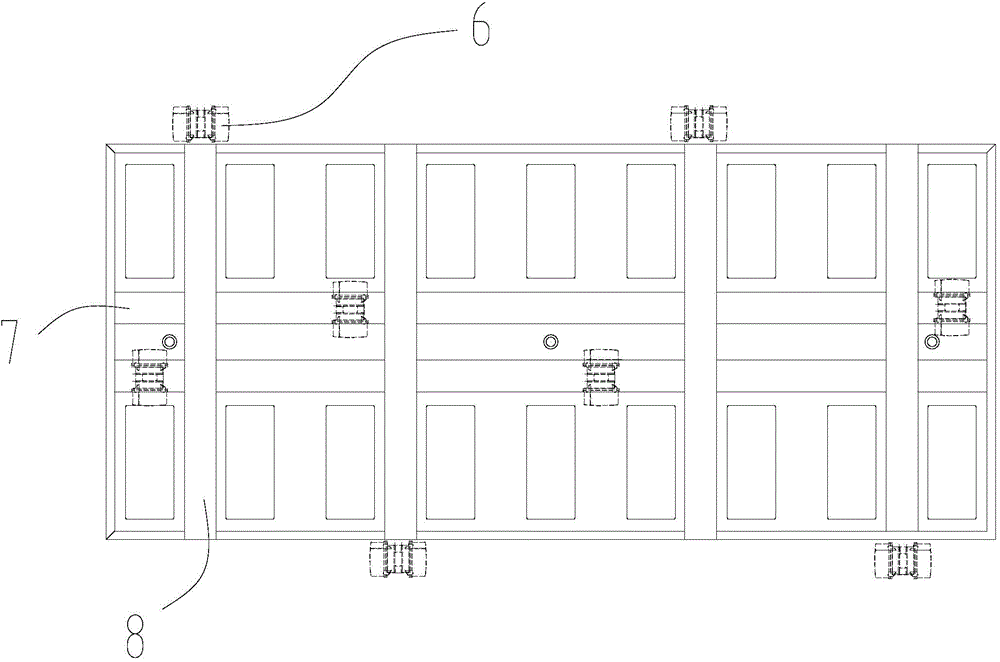

[0034] In the technical conditions for the manufacture of CTRSⅢ type two-way pretensioned prestressed concrete track slabs within the China Railway No. 23 Bureau, it is clearly stipulated that "concrete should be vibrated with an attached vibrator, and the vibration frequency and amplitude should be determined according to the test before concrete pouring. and vibration time and other technical requirements”; “Concrete slump should not be greater than 140mm”; “There should be no laitance on the bottom of the track slab” and other technical requirements. The engineering practice of the 23rd Bureau in recent years has shown that there are many air bubbles or sticky skin quality problems on the four sides of the prefabricated track slab. During production, repairs are required to make up for this appearance defect, which increases labor costs. At the same time, there are also concrete defects. The vibration segregation problem and the local mortar accumulation problem seriously af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com