High-efficiency cooling roughed powder drawing stainless steel wire drawing die

A stainless steel wire, rough drawing technology, applied in the direction of drawing dies, etc., can solve the problems of unfavorable wire packaging, difficult to guarantee the mechanical properties of the wire, affecting the wire, etc. It is easier to ensure the strength and other properties, the surface quality is easy to ensure, and the leakage of lubricating powder can be avoided. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

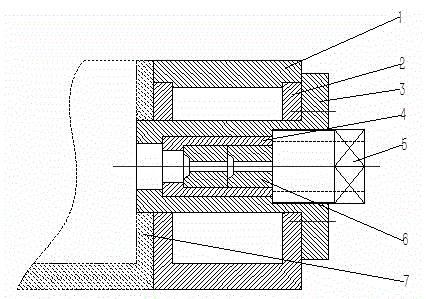

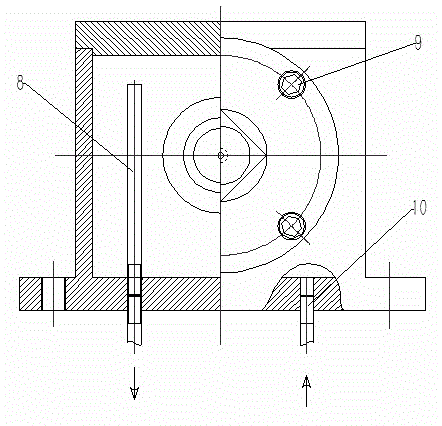

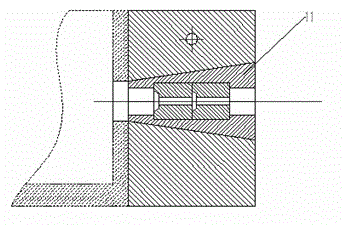

[0023] see figure 1 and figure 2 , the present invention relates to a high-efficiency cooling rough drawing powder drawing stainless steel wire drawing mold, the mold includes a mold box 2, the mold box 2 is a hollow box-shaped structure, and the top of the mold box 2 is tightly fitted and installed There is a mold box cover 1, and a mold base 3 is connected between the left and right box walls of the mold box 2, and the mold base 3 is embedded with a mold cover 4, and a drawing mold 6 (preferably , the mold case 4 is a cylindrical structure with a step hole, the drawing die 6 is installed in the step hole), the bottom of the mold box 2 is provided with a water inlet and a water outlet;

[0024] Specifically, the mold base 3 includes a cylindrical structure connected between the left and right walls of the mold box 2, and a flange connected to one end of the cylindrical structure. The box walls of the box 2 are connected (preferably, the flange is provided with a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com