Moving spray booth for electrostatic powder spraying

An electrostatic powder and movable technology, which is applied to electrostatic spraying devices, devices for coating liquid on the surface, coatings, etc., can solve problems such as hindering the work of operators and inconvenient cleaning or maintenance for operators, and achieve the goal of reducing workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

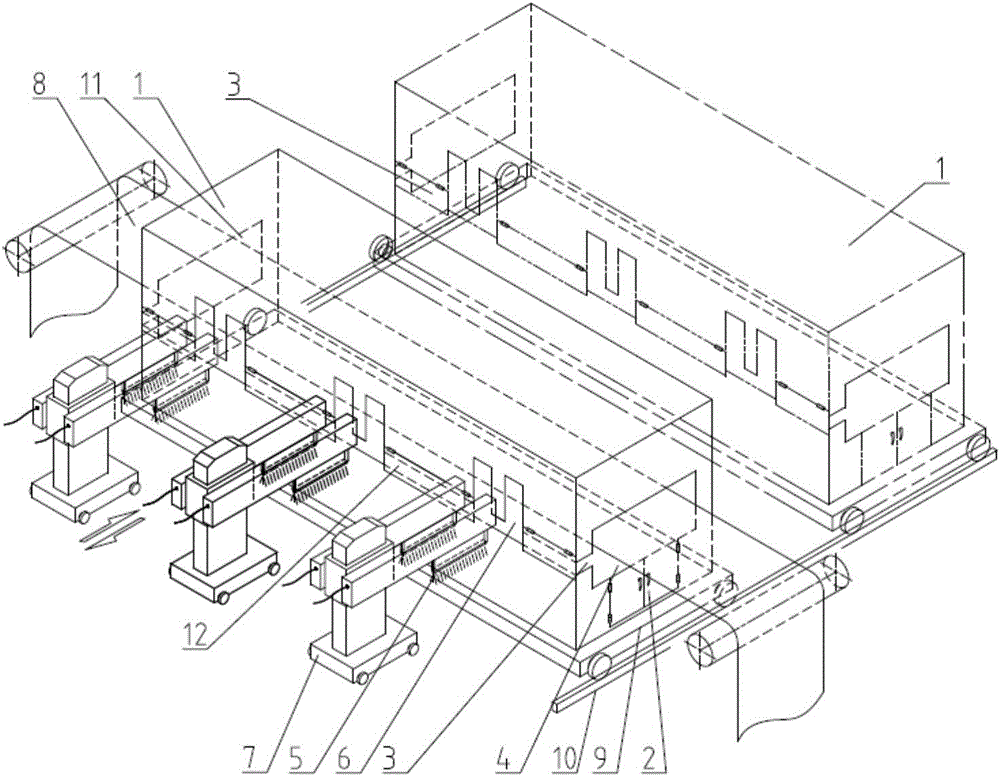

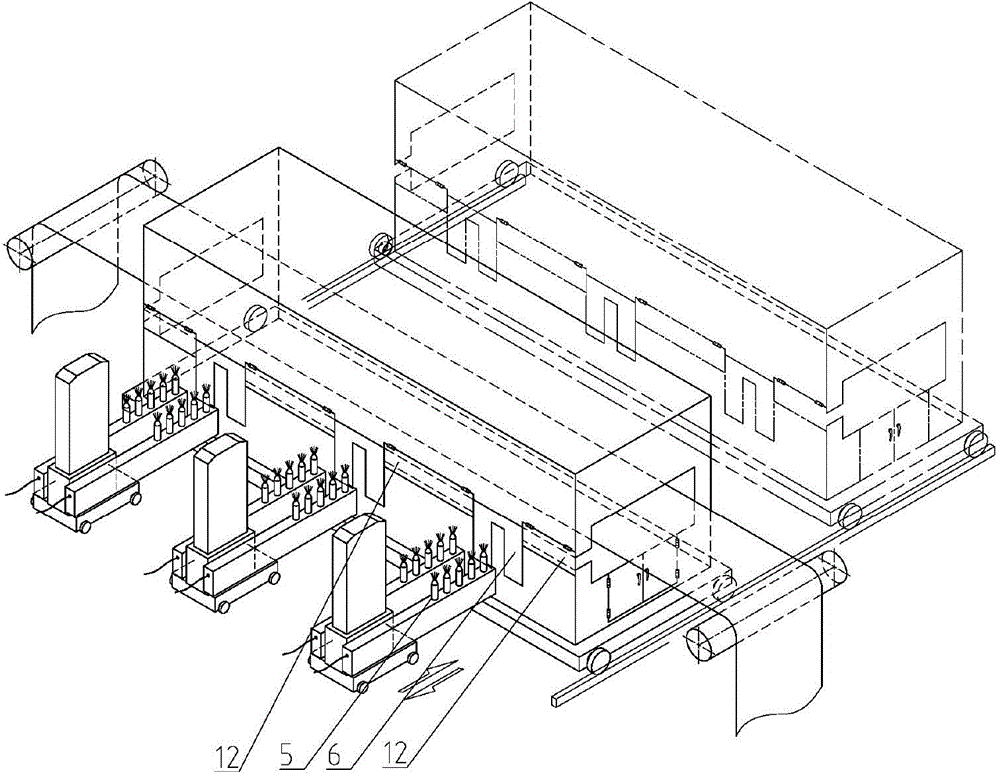

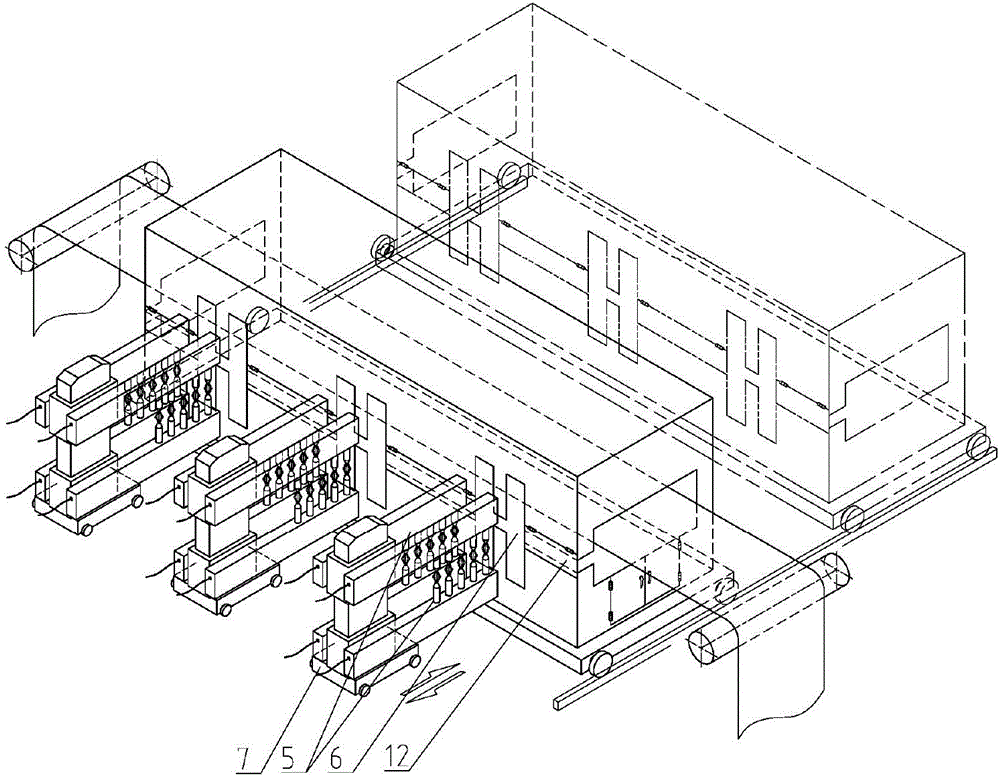

[0026] The specific embodiments of the movable powder booth for electrostatic powder spraying according to the present invention will be further described below with reference to the accompanying drawings.

[0027] see figure 1 As shown, the movable powder booth for electrostatic powder spraying according to the present invention includes: a room body 1, the room body has an inlet 4, an outlet 11 for the substrate 8 to be coated to pass through, and a spraying device for the sprayer to move the trolley 7 in and out of the beam Device opening 6. in:

[0028] In order to ensure continuous production, a horizontal gap 3 is provided on one side wall of the house body 1 parallel to the direction of the production line, and the horizontal gap 3 is communicated with the above-mentioned inlet 4 and outlet 11, so that the coated substrate can enter the powder booth from this horizontal gap 3. And the shape of the notch is adapted to the natural hanging state of the coated substrate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com