A high-efficiency mist eliminator that is not easy to scale

A high-efficiency, mist eliminator technology, applied in the field of desulfurization, can solve the problems of the surface of the mist eliminator being too smooth, the droplet collision is not very strong, and the demisting effect of the mist eliminator is not very good. Anti-fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

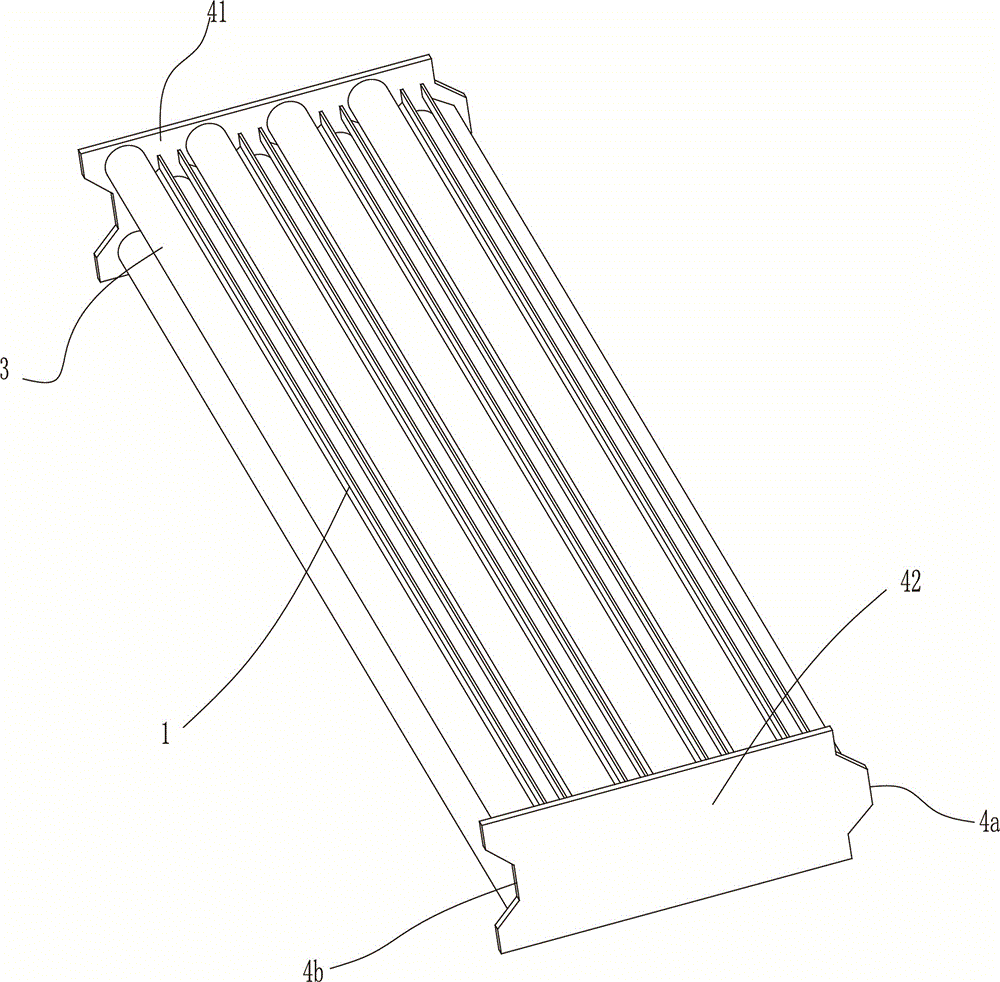

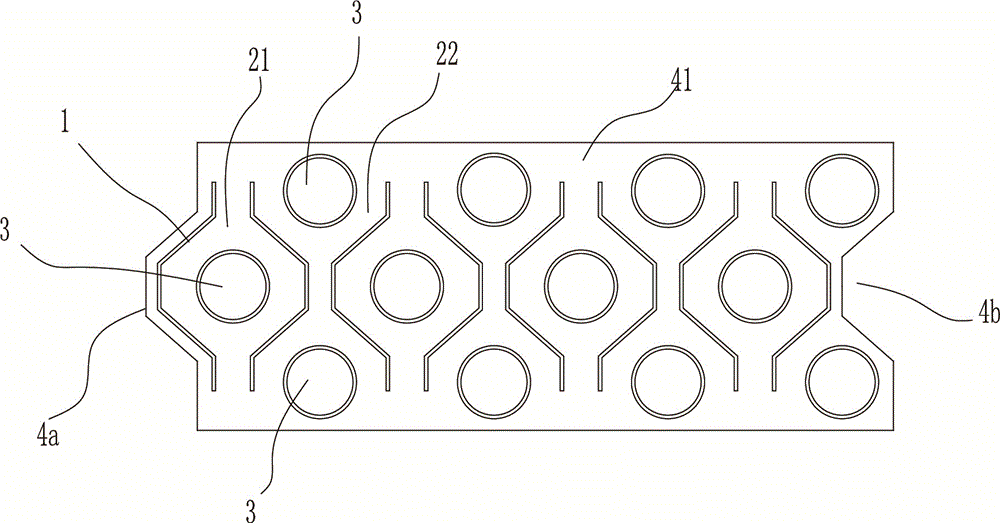

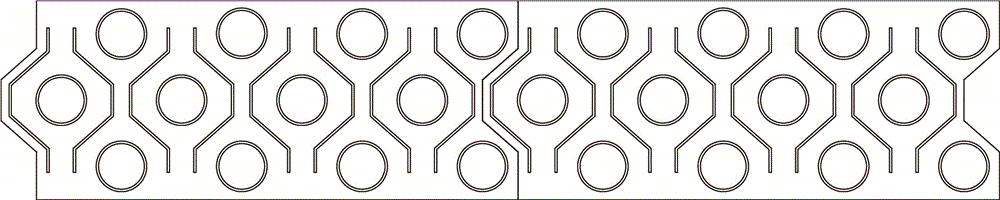

[0017] see figure 1 and figure 2 A high-efficiency mist eliminator that is not prone to fouling includes passages 21, 22 surrounded by baffles 1 and two baffles 41, 42, and each surface of the spoiler 1 located in the passages 21, 22 is flat. A circular tube 3 is arranged at the turning point of the channels 21, 22, and the tube 3 divides the turning point of the channels 21, 22 into two flow passages, and the sum of the cross-sectional areas of the two flow passages is smaller than the section area of the rest of the passages 21, 22. area. Each baffle plate 41, 42 has a raised portion 4a and a recessed portion 4b, and the shapes of the raised portion and the recessed portion are complementary to each other. Both ends of the tube 3 and the baffle 1 are fixed on the baffles 41,42.

[0018] There are two kinds of passages 21 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com