A complete set of equipment for ripening and cooling in the production of sweet potato flour

A complete set of equipment, the technology of sweet potato flour, applied in cooling complete sets of equipment, mature fields, can solve the problems of high viscosity of sweet potato flour, easy jamming of mud stirring pump, limited productivity, etc., to achieve rapid maturity, small footprint, saving labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

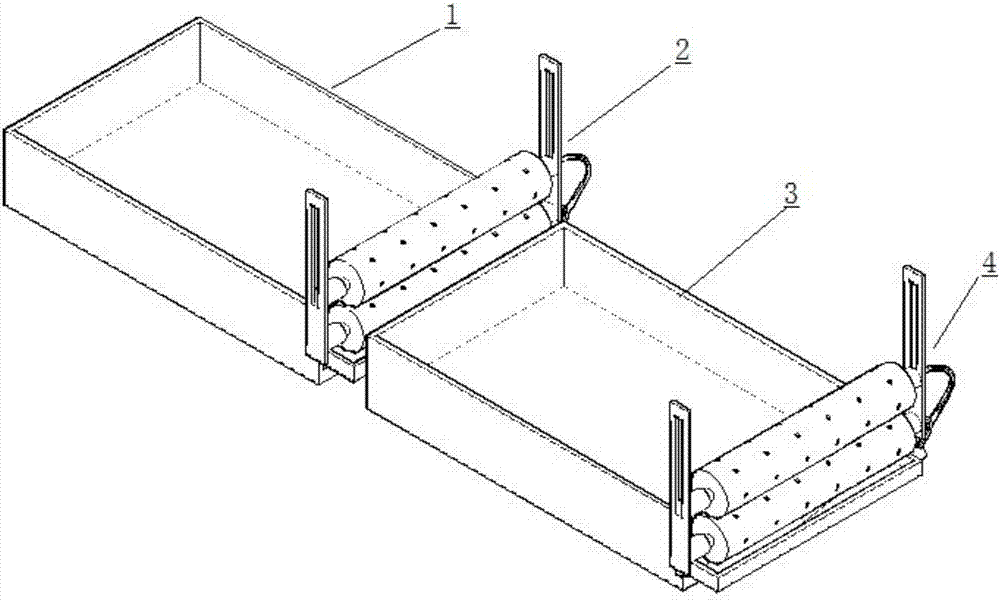

[0024] Such as figure 1 A complete set of mature and cooling equipment in the production of sweet potato flour shown; including boiling table 1, transmission equipment A2, cooling platform 3 and transmission equipment B4, water boiling platform 1, transmission equipment Ab, cooling platform 3 and transmission equipment B4 Installed on the workbench successively, the bottom of the poaching table 1 has a heating wire.

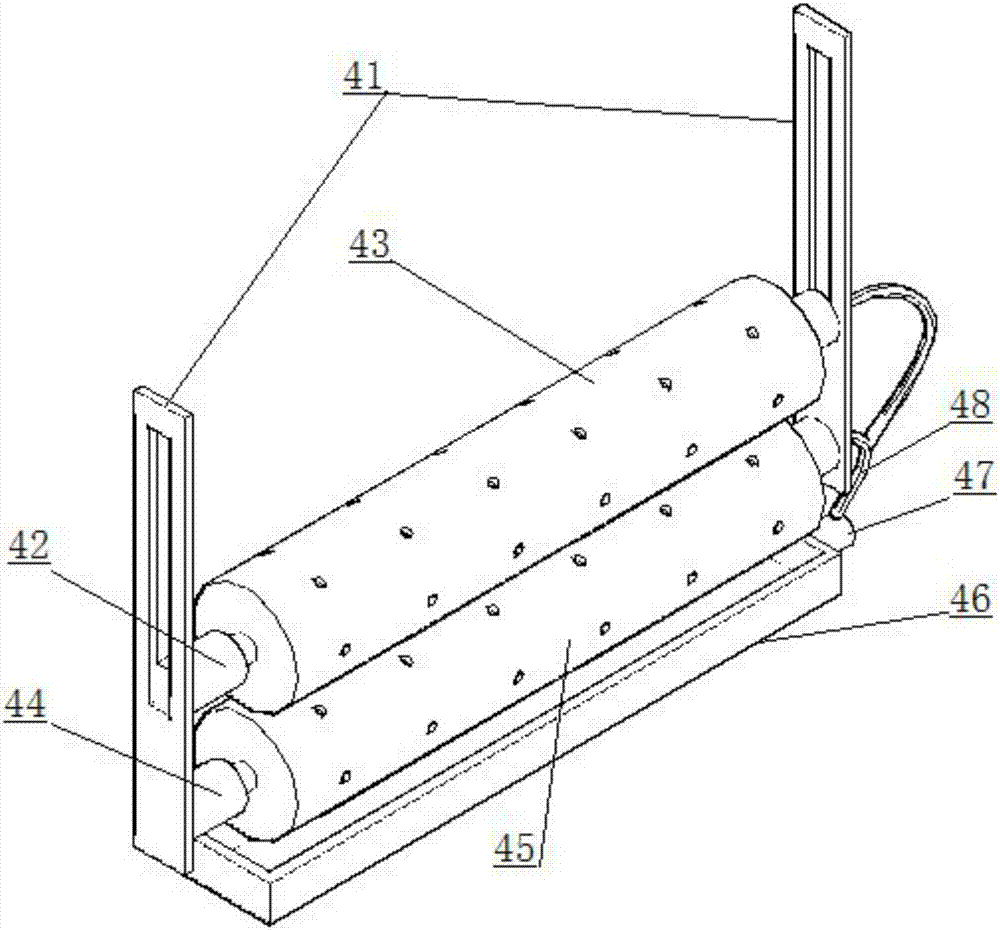

[0025] Such as figure 2 The conveying equipment A2 shown includes a lift A21, a motor Aa22, a roller Aa23, a motor Ab24 and a roller Ab25; wherein the rotor of the motor Ab24 is connected to one end of the roller Ab25; there are two lifts A21, which are located in a horizontal position, and the one on the right is The bottom of the lifting frame A21 is movably connected with the other end of the roller Ab25 through a bearing, and the left lifting frame A21 is fixed on the bottom of the motor Ab24; the rotor of the motor Aa22 is connected with one end of the rol...

Embodiment 2

[0033] Such as figure 2 As shown, the conveying device A2 also includes a water storage tank A26, and the water storage tank A26 is under the vertical direction of the drum Aa23 or the drum Ab25. Others are the same as embodiment one.

[0034] This embodiment is mainly to solve the problem that the water falling from the conveying equipment A2 pollutes the conveying belt.

Embodiment 3

[0036] Such as image 3 As shown, the transfer device B4 also includes a water storage tank B46, which is under the vertical direction of the drum Ba43 or the drum Bb45. Others are the same as implementation one or implementation two.

[0037] This embodiment is mainly to solve the problem that the water falling from the conveying equipment B4 pollutes the conveying belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com