Wireless power transmission device, method for controlling heat generated by wireless power transmission device, and production method for wireless power transmission device

A technology of wireless power transmission and heat control, applied in circuit devices, battery circuit devices, transmission systems, etc., can solve problems such as increased heat generation and shortened life of electronic parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

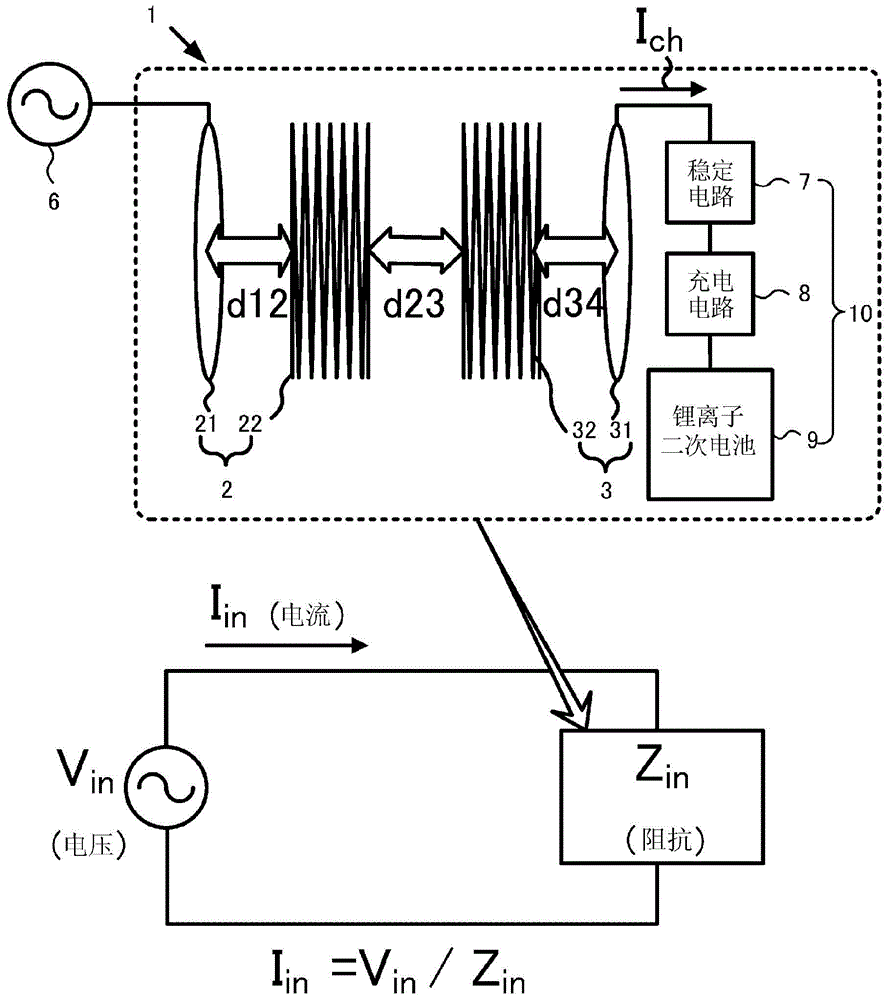

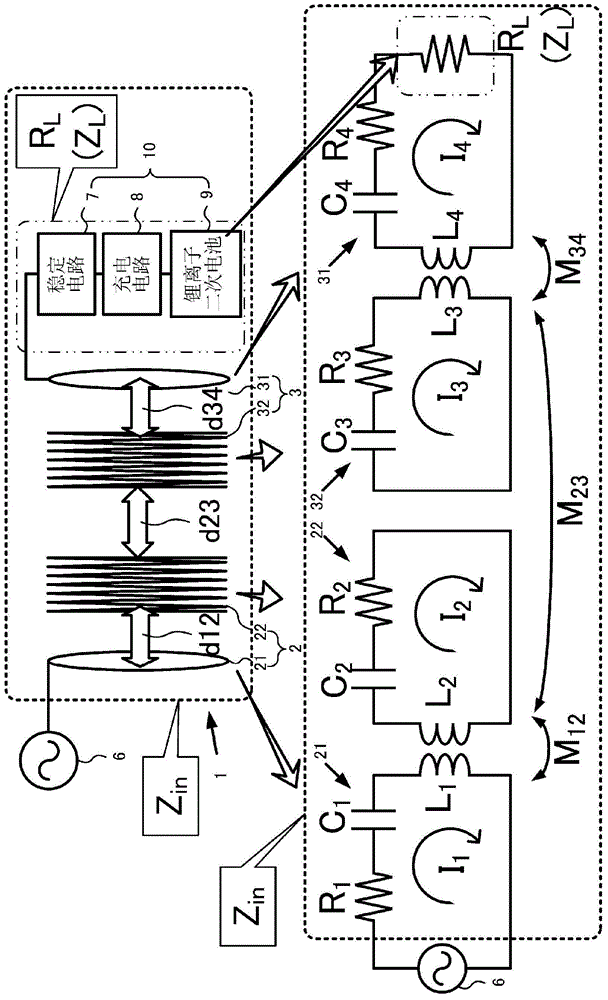

[0044] Embodiments of the wireless power transmission device, the heat generation control method of the wireless power transmission device, and the manufacturing method of the wireless power transmission device according to the present invention will be described below. First, the wireless power transmission device 1 used in this embodiment will be described.

[0045] (Structure of wireless power transmission device 1)

[0046] Such as figure 1 As shown, the wireless power transmission device 1 includes a power supply module 2 including a power supply coil 21 and a power supply resonator 22 , and a power receiving module 3 including a power receiving coil 31 and a power receiving resonator 32 . Furthermore, an AC power source 6 having an oscillation circuit for setting the driving frequency of electric power supplied to the power supply module 2 to a predetermined value is connected to the power supply coil 21 of the power supply module 2 , and to the power reception coil 31...

other Embodiment approach

[0142] In the description of the above-mentioned manufacturing method, the wireless headphone 200 was exemplified and described, but as long as it is a device equipped with a secondary battery, it can also be used in a tablet PC, a digital camera, a mobile phone, and an earphone-type music player. , hearing aids, sound collectors, etc.

[0143] In addition, in the above description, the case where the wireless power transmission device 1 is mounted on a portable electronic device is assumed to be described. However, the application is not limited to these small devices. Wireless charging systems for electric vehicles (EVs), smaller wireless intragastric cameras for medical use, etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com