Defect inspection apparatus, and defect inspection method

A defect inspection and defect technology, applied in the direction of measuring devices, optical devices, and material analysis through optical means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

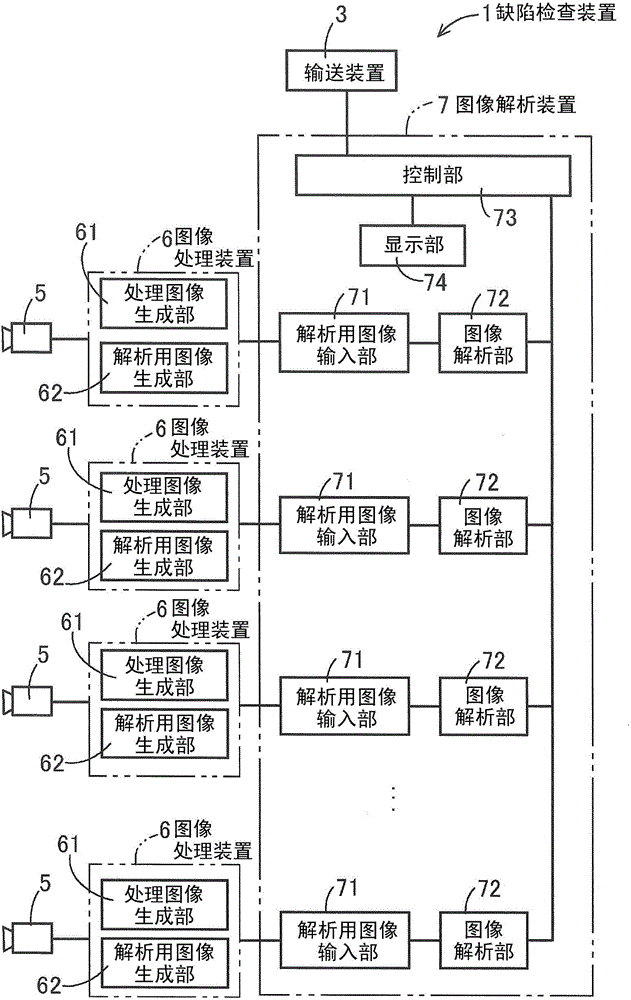

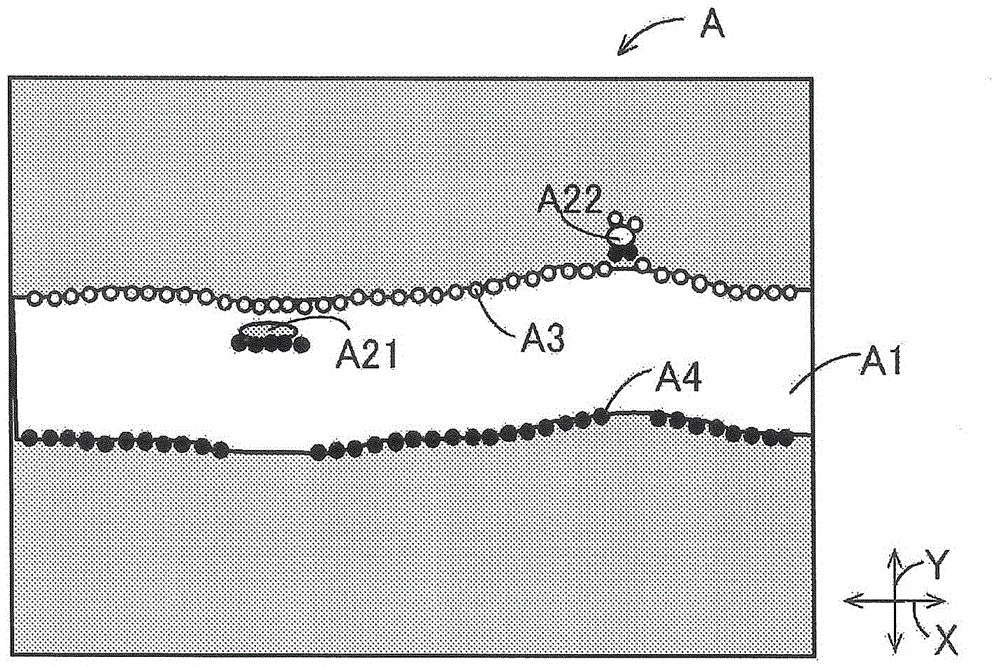

[0066] figure 1 It is a schematic diagram which shows the structure of the defect inspection apparatus 1 which concerns on one Embodiment of this invention. figure 2 It is a block diagram showing the configuration of the defect inspection device 1 . The defect inspection device 1 of the present embodiment is a device for detecting defects in a sheet-shaped molded article 2 of thermoplastic resin or the like. The defect inspection method of the present invention is executed by the defect inspection device 1 .

[0067] The sheet-shaped molded object 2 as the object to be inspected is formed by passing the thermoplastic resin extruded from the extruder through the gap between the rollers, performing treatments such as smoothing the surface or giving unevenness, and cooling on the conveying rollers. At the same time, it is pulled by the pull roller. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com