Coal mining machine motor speed regulating method based on path optimization and speed regulating control

A technology of path optimization and speed regulation method, applied in control systems, AC motor control, slitting machinery, etc., can solve the problems of lack of self-adaptation, slow motor speed response, large load fluctuations, etc., to achieve fewer people or remote work, improve efficiency and stability, and reduce the effect of load fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

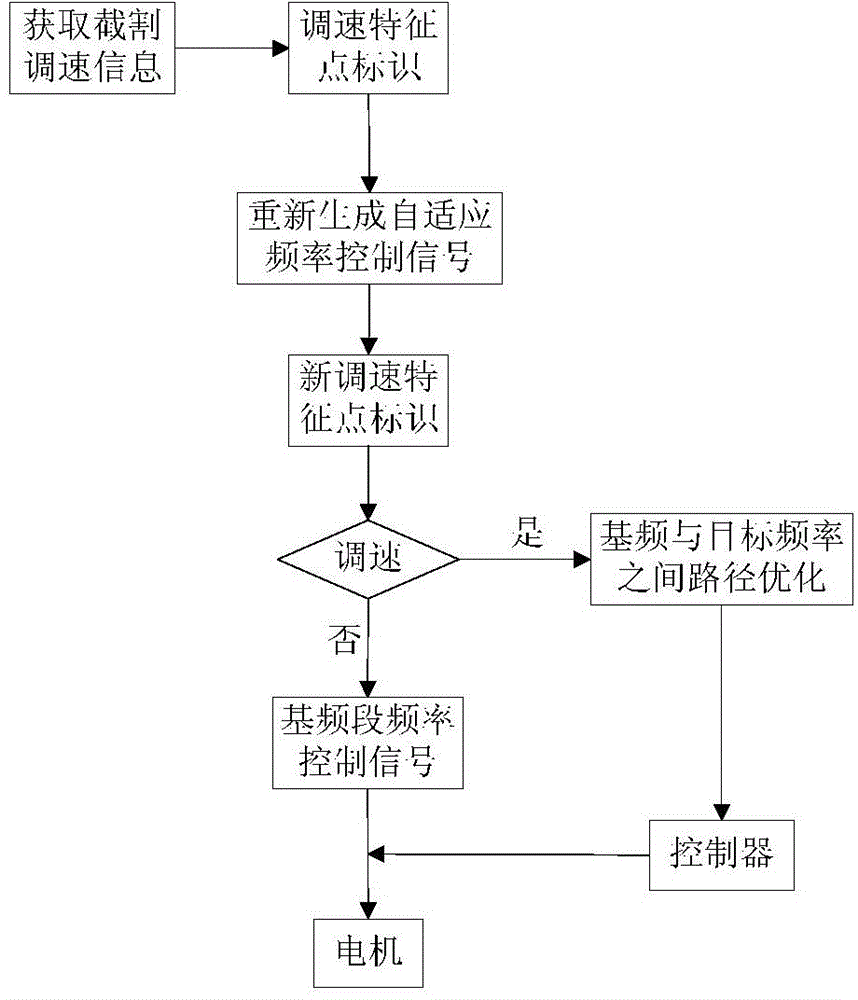

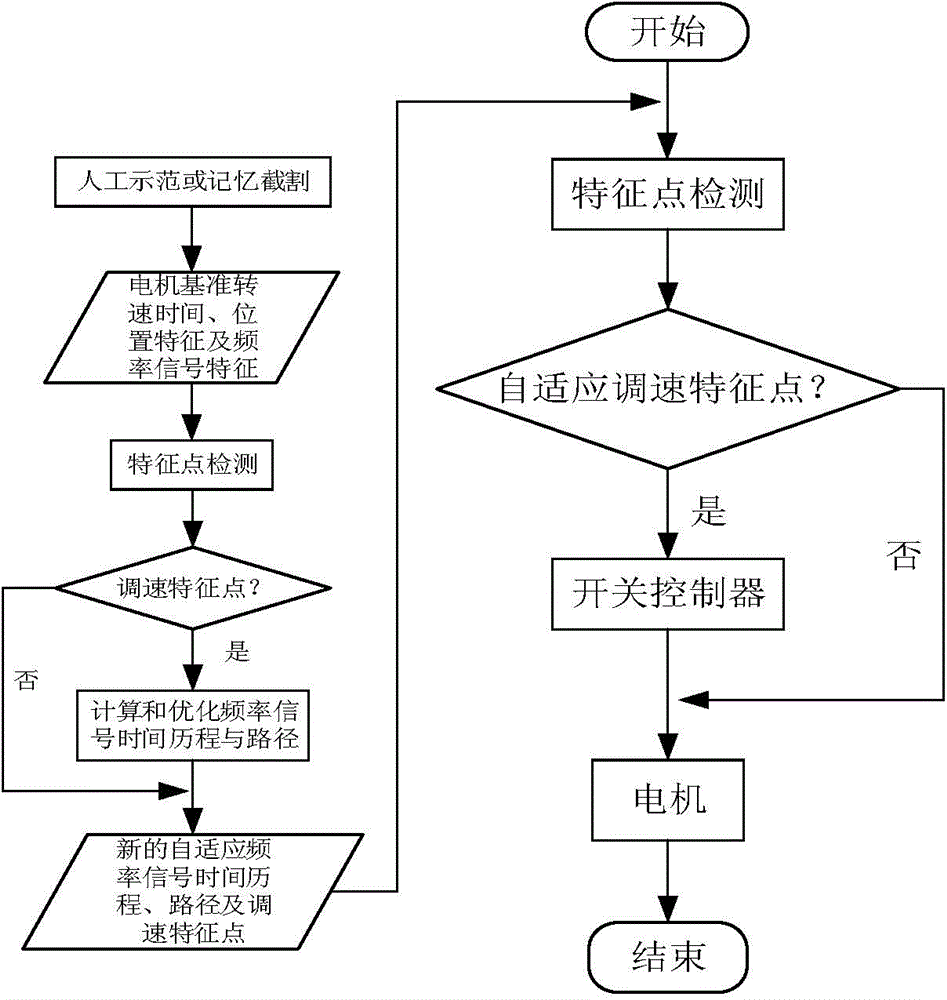

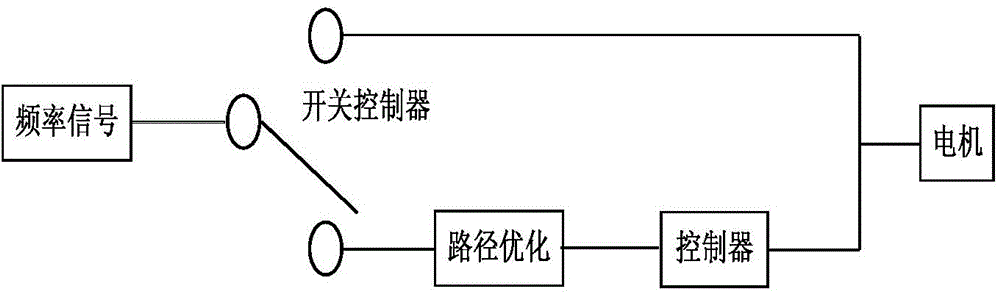

[0025] The invention provides a shearer motor speed regulation method based on path optimization and speed regulation control. Based on coal and rock prediction information, the traction speed and cutting speed of the shearer are adjusted to achieve a certain self-adaptive speed regulation. The block diagram of method of the present invention is as figure 1 shown. figure 2 It is a schematic structural representation of the specific principle of the method of the present invention, and the method of the present invention specifically includes the following steps:

[0026] 1) During the cutting process of a fully-mechanized mining face, the coal and rock characteristics of the coal mining face are obtained through manual demonstration operation or memory cutting; the coal and rock characteristics include the time feature points during cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com