Passive component with temperature compensation and electronic device using same

An electronic device and negative temperature coefficient technology, applied in the direction of output power conversion devices, electrical components, high-efficiency power electronic conversion, etc., to achieve the effect of increasing output voltage, reducing partial pressure difference, and accurate sensing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Reference will now be made in detail to the exemplary embodiments of the present invention, examples of which are illustrated in the accompanying drawings. In addition, elements / members with the same or similar numbers used in the drawings and embodiments are used to represent the same or similar parts.

[0054] After careful research, the inventors of the present application found that the reason why the current technology uses NTC resistors to measure the voltage difference across the inductor is inaccurate because: the NTC resistor and the inductor are not in direct contact and there is air. Air is one of the media for heat dissipation. When the negative temperature coefficient resistor reacts the heat of the inductor across the air, part of the heat will be dissipated with the air. Therefore, the NTC resistor cannot accurately compensate the error caused by the current flowing through the inductor.

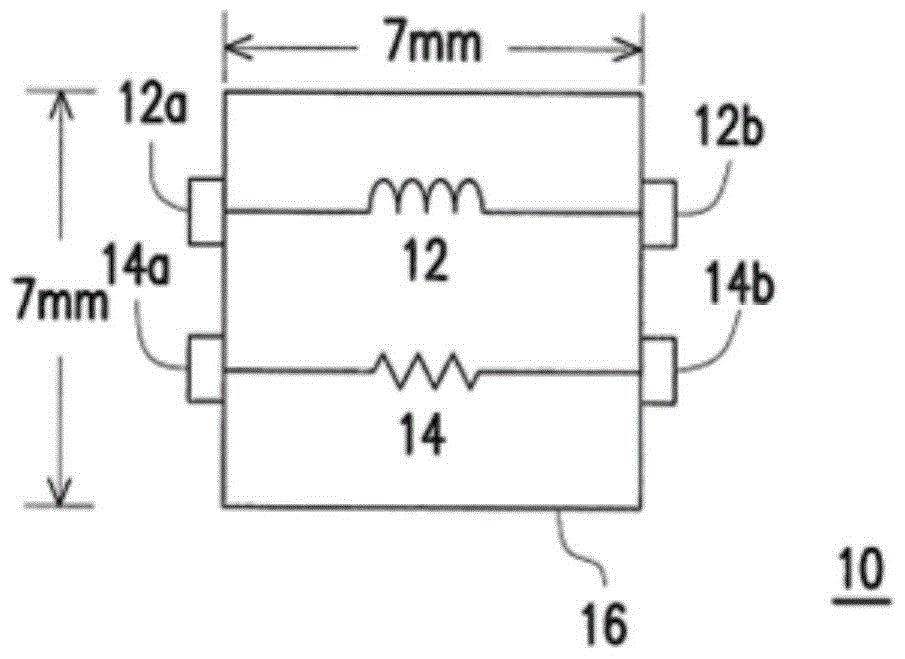

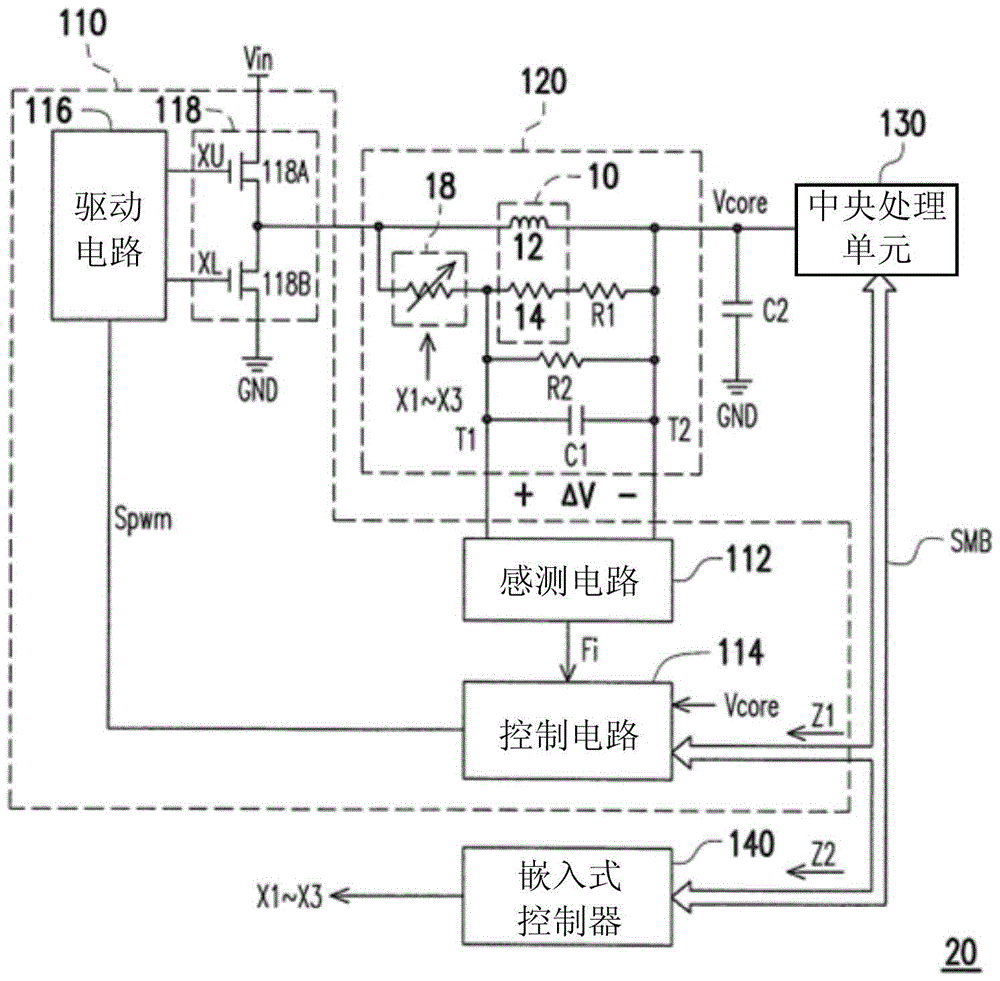

[0055] figure 1 It is a configuration diagram of a passive comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com