Ventilation steel channel, manufacturing method of ventilation steel channel, ventilation structure and motor

A technology of ventilation channel steel and ventilation slot, which is applied in the manufacture of stator/rotor body, magnetic circuit shape/style/structure, magnetic circuit static parts, etc. Lifting, ventilation channel difficulty and other problems, to achieve the effect of strengthening cooling and heat dissipation, improving reliability, and good cooling and heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

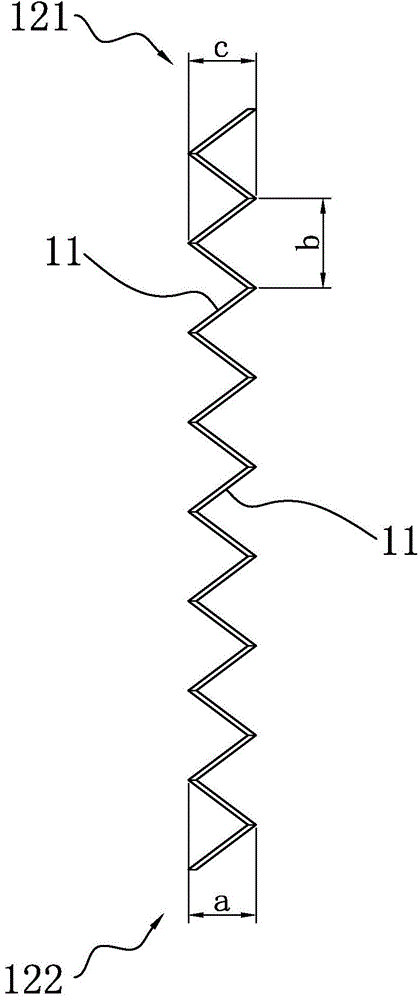

[0044] Such as figure 1 As shown, it is a schematic structural diagram of the ventilation channel steel in Embodiment 1 of the present invention. The ventilation channel steel of Embodiment 1 of the present invention comprises at least four sections (for example, seventeen sections shown in the figure) ventilation channel steel sections 11 connected successively, wherein the clip between every two sections of adjacent ventilation channel steel sections 11 The angle is less than 180°, and among the ventilation channel steel sections 11 connected in sequence by every three sections, the ventilation channel steel sections 11 located on both sides are distributed on both sides of the ventilation channel steel section 11 located in the middle.

[0045] The ventilation channel steel in Embodiment 1 of the present invention is different from the commonly used traditional "I"-shaped ventilation channel steel and strip-shaped ventilation channel steel. The channel steel is not on a st...

Embodiment 2

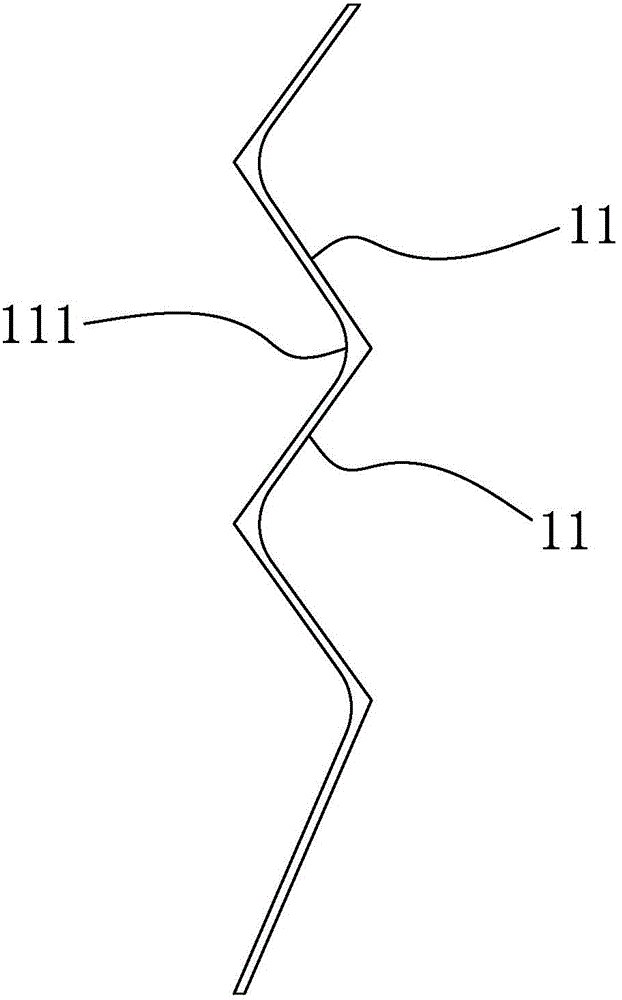

[0054] Such as figure 2 As shown, it is a schematic structural diagram of the ventilation channel steel of the second embodiment of the present invention. The difference between the ventilation channel steel of this embodiment and the ventilation channel steel of Embodiment 1 is that a chamfer 111 is provided at the junction of every two adjacent ventilation channel steel sections 11, and the chamfer 111 is located at the junction of less than 180 ° on the side of the angle. The wind resistance is greater on the side where the included angle of the junction is less than 180°, and the chamfer structure at this position can reduce the wind resistance.

[0055] In addition, the number of sections of the ventilation channel steel section 11 of the present embodiment is five sections, which is less than that of the first embodiment, so the angle between every two sections of adjacent ventilation channel steel section 11 is relatively larger, like this It can also play a role in ...

Embodiment 3

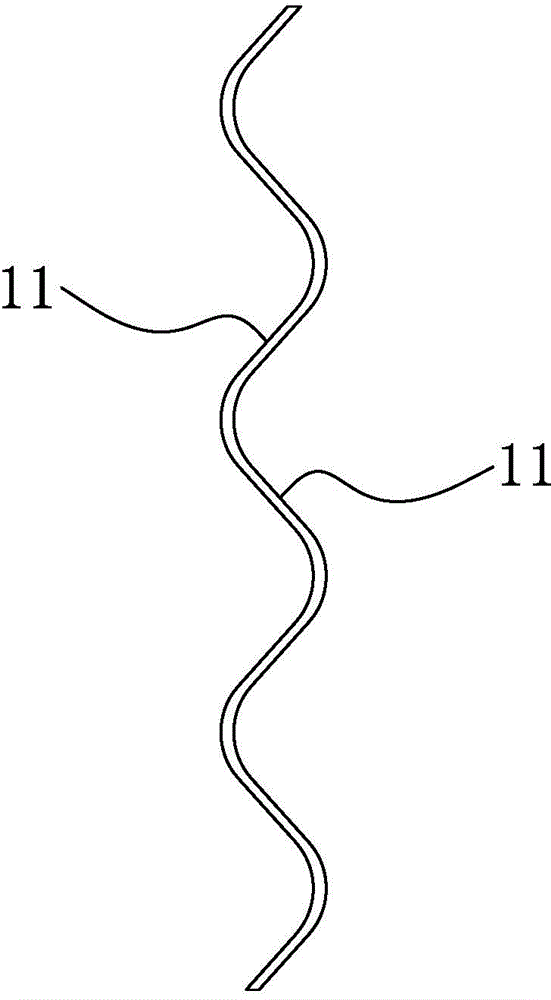

[0057] Such as image 3 As shown, it is a structural schematic diagram of the ventilation channel steel of the third embodiment of the present invention. The main difference between the ventilation channel steel of this embodiment and the ventilation channel steel of the previous embodiments is that the ventilation channel steel of this embodiment is wavy. The wavy shape itself is also a multi-turn shape, and the wavy design can make the surface of the ventilation channel steel in contact with the cooling gas streamlined, so that the ventilation channel steel has a small wind resistance. Compared with the traditional ventilation channel steel, the use of this shape can also increase the heat dissipation area in an appropriate amount.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com