Aging method of low-voltage electrical appliances with double gold structure

A technology of low-voltage electrical appliances and complete machines, which is applied in the field of long-time protection electrical appliances to shorten the adjustment time, improve reliability, and avoid zero-point drift problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

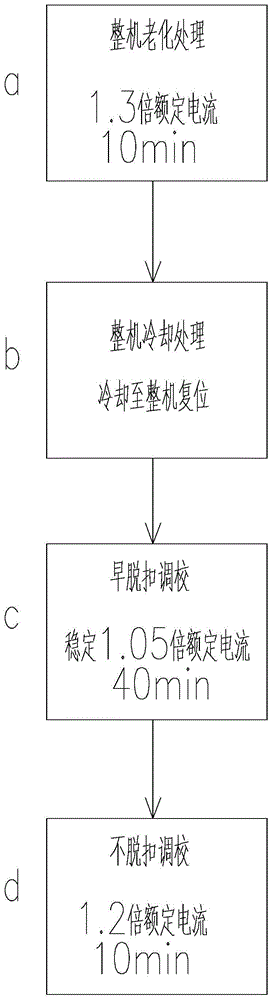

[0031] The second embodiment of the inventive method comprises the following steps:

[0032] 1. Before the calibration of low-voltage electrical products is completed after assembly, the complete machine of low-voltage electrical products is connected to 6 times the rated current of the three-phase main circuit on the automatic tooling line, and the current is gradually reduced to 1.2 times. Aged for 8 minutes.

[0033] 2. After the aging of the whole machine is completed, the whole machine is cooled for 7 minutes until the product is reset.

[0034] 3. Connect the three-phase 1.05 times the rated current on the long-delay calibration platform, and stabilize it for 25 minutes to adjust the early trip product. Because the product has undergone high-current aging in the first step, the product has obtained enough heat, which will greatly shorten the thermal equilibrium time of long-delay calibration by 1.05 times.

[0035] 4. Turn on 1.2 times the rated current for 50 minutes ...

no. 3 example

[0036] The third embodiment of the inventive method comprises the following steps:

[0037] 1. Before the calibration of low-voltage electrical products is completed after assembly, the complete machine of low-voltage electrical products is connected to 6 times the rated current of the three-phase main circuit on the automatic tooling line, and the current is gradually reduced to 1.3 times. Aged for 5 minutes.

[0038] 2. After the aging of the whole machine is completed, the whole machine is cooled for 8 minutes until the product is reset.

[0039] 3. Connect the three-phase 1.05 times the rated current on the long-delay calibration platform, and stabilize for 20 minutes to adjust the early tripping product. During this process, the early tripping of the product can be adjusted for the product.

[0040] 4. Turn on 1.2 times the rated current for 2 hours on the long-time delay calibration platform, and the product that does not trip during this process can be calibrated.

no. 4 example

[0041] The fourth embodiment of the inventive method comprises the following steps:

[0042] 1. Before the calibration of low-voltage electrical products is completed after assembly, the whole low-voltage electrical product is connected to the three-phase main circuit with 1.5 times the rated current to age the whole machine for 20 minutes.

[0043] 2. After the aging of the whole machine is completed, the whole machine is cooled for 10 minutes until the product is reset.

[0044]3. Connect the three-phase 1.05 times rated current on the long-delay calibration platform, stabilize for 30 minutes to adjust the early tripping product, during this process, the early tripping of the product can be adjusted for the product.

[0045] 4. Turn on 1.2 times the rated current for 30 minutes on the long-time delay calibration platform, and the product that does not trip during this process can be adjusted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com