Self-cooling cable and cooling method thereof

A self-cooling and cable technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of difficult fire extinguishing, cable breakdown, cable spontaneous combustion hazards, etc., to achieve automatic control of sliders, avoid rainwater entry, and improve ventilation effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0013] Specific embodiment 1: the cable structure of the present invention comprises a plurality of cable cores with insulating layers, wrapping tapes and outer sheath layers, each cable core is provided with an insulating layer, and multiple cable cores with insulating layers are placed on the winding Inside the tape layer, the outer sheath layer is outside the wrapping tape layer. The cable structure also includes a hollow ventilation layer, which is used to take away the heat generated when the cable is working, so as to prevent the cable from breaking down and burning if the temperature is too high.

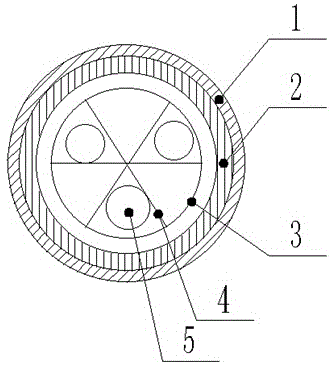

[0014] The hollow ventilation layer is a ventilation pipe with a dot structure, and a support plate is provided inside the pipe to avoid extrusion of the cable core and deformation of the ventilation pipe. Such as figure 1 , the support pipe divides the ventilation pipe into several cavities, and the cable cores with insulating layers are placed in the cavities at intervals ...

specific Embodiment 2

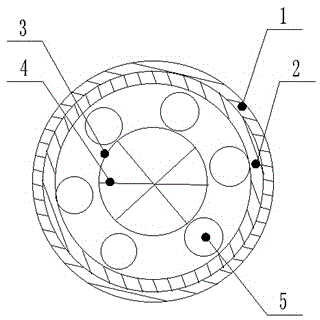

[0018] Specific embodiment 2: as figure 2 The structure of the ventilation pipe and the support plate in the hollow ventilation layer is the same as that of Embodiment 1, but the cables with insulating layers are placed on the periphery of the ventilation pipe. This structure is easier to process than Embodiment 1.

specific Embodiment 3

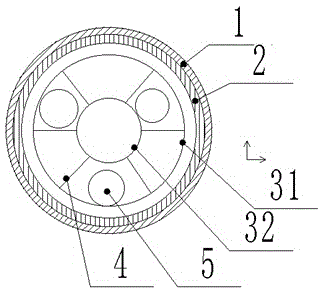

[0019] Specific embodiment 3: as image 3 , the hollow ventilation layer includes a ventilation pipe, the section of the ventilation pipe is a ring structure, including an inner pipe and an outer pipe, a support plate is provided between the inner pipe and the outer pipe, and in the cavity separated by the support plate, insulation layers are placed at intervals The cable core, the ventilation pipe and the support plate are all mesh structures. This scheme has a large ventilation area of the cable core and a good ventilation effect.

[0020] The opening and closing of the fan and the working power are controlled by the PLC controller, and the PID algorithm is set in the PLC controller to control the opening, closing and working efficiency of the fan.

[0021] First set a target temperature difference, judge whether to turn on the fan by the air temperature inside the cable transmitted by the temperature sensor, set e as the target temperature, and set e at the same time 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com