Random matrix moire fringe anti-fake pattern and manufacturing method thereof

A technology of random matrix and moiré fringe, applied in the field of anti-counterfeiting, can solve the problems of simple production method, difficult to see hidden content, poor detection effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

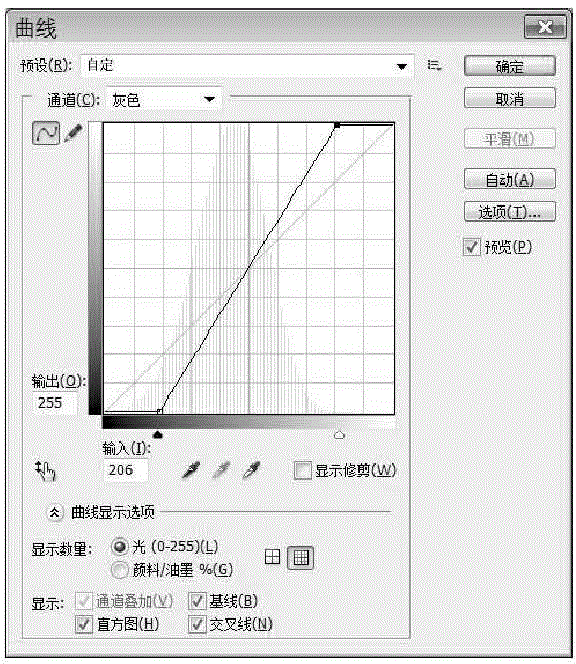

Method used

Image

Examples

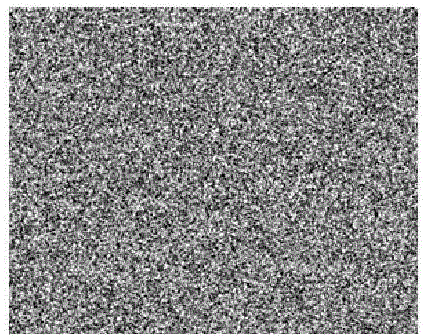

preparation example Construction

[0119] The anti-counterfeit pattern of random matrix moiré fringe with two layers of hidden characters obtained by the preparation method of the present invention is obviously better than ordinary parallel line moiré fringe, and no matter it is seen with naked eyes or with a magnifying glass, it can only be seen as disorderly. Dotted lines, but when using a grating film to detect, the detection effect is obvious, which is better than the parallel line Moiré fringe. Due to the strong professionalism of this technology, ordinary anti-counterfeiting personnel cannot imitate it, so it can achieve better anti-counterfeiting effect.

[0120] The present invention also includes a method for making a random matrix moiré fringe anti-counterfeiting pattern with three layers of hidden characters, comprising the following steps:

[0121] (1) Use Photoshop to make a grayscale image, and save the image in tif format;

[0122] (2) Use the Vector tool in the GS Layout anti-counterfeiting soft...

Embodiment 1

[0162] A random matrix Moiré fringe anti-counterfeiting pattern with double-layer hidden text, including random matrix A1, random matrix A2, random matrix B1, random matrix B2 and double-layer hidden text in four matrices with squares as basic elements; The side length of the random matrix A1 square is 0.06mm, and the square spacing is equal to the value of the side length; the random matrix A2 is obtained by copying the random matrix A1 in situ and then moving vertically upwards by 0.06mm; the random matrix B1 is the The random matrix A1 is copied in situ to obtain b1, and then the center point of b1 is rotated 90° clockwise to obtain it; the random matrix B2 is obtained by copying the random matrix A2 in situ to obtain b2, and then the center point of b2 is rotated 90° clockwise to obtain .

[0163] A method for making a random matrix moiré fringe anti-counterfeiting pattern with double-layer hidden text comprises the following steps:

[0164] (1) Use Photoshop to make a gr...

Embodiment 2

[0183] A random matrix Moiré fringe anti-counterfeiting pattern with double-layer hidden text, including random matrix A1, random matrix A2, random matrix B1, random matrix B2 and double-layer hidden text in four matrices with squares as basic elements; The side length of the random matrix A1 square is 0.2mm, and the square spacing is also 0.2mm; the random matrix A1 is rotated 30° clockwise with its center point as the reference; the random matrix A2 is copied in situ of the random matrix A1 Then move vertically upwards by 0.2 mm to obtain; the random matrix B1 is obtained by copying the random matrix A1 in situ, and then rotate the center point of b1 clockwise by 90°; the random matrix B2 is obtained by copying the random matrix A2 in situ Get b2, and then rotate the center point of b2 90° clockwise to get it.

[0184] A method for making a random matrix moiré fringe anti-counterfeiting pattern with double-layer hidden text comprises the following steps:

[0185] (2) Use Ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com