Topological optimization method for constraining and damping blades of aeroengine

An aero-engine, restrained damping technology, applied in instruments, calculations, electrical and digital data processing, etc., can solve the problems of increasing additional mass, unfavorable lightweight of aero-engines, etc., to achieve the best damping and vibration reduction effect, and improve the resistance to fatigue damage. Ability, the effect of small vibration stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

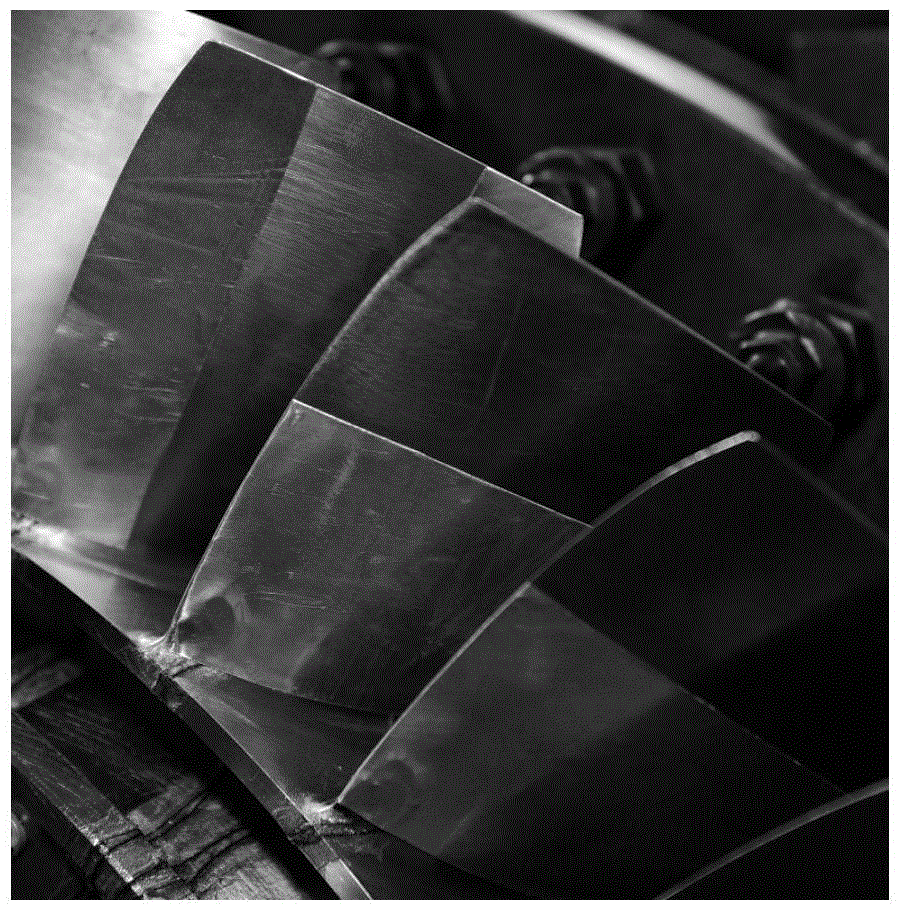

[0028] This embodiment provides a topology optimization method for constrained damping aeroengine blades, which is characterized in that: the topology optimization method for constrained damping aeroengine blades uses lightweight aluminum foil as the constraining material, which is sequentially pasted on the surface of the aeroengine blades Viscoelastic material and constrained material, conduct constrained damping treatment on blades, and establish finite element model of constrained damped blades;

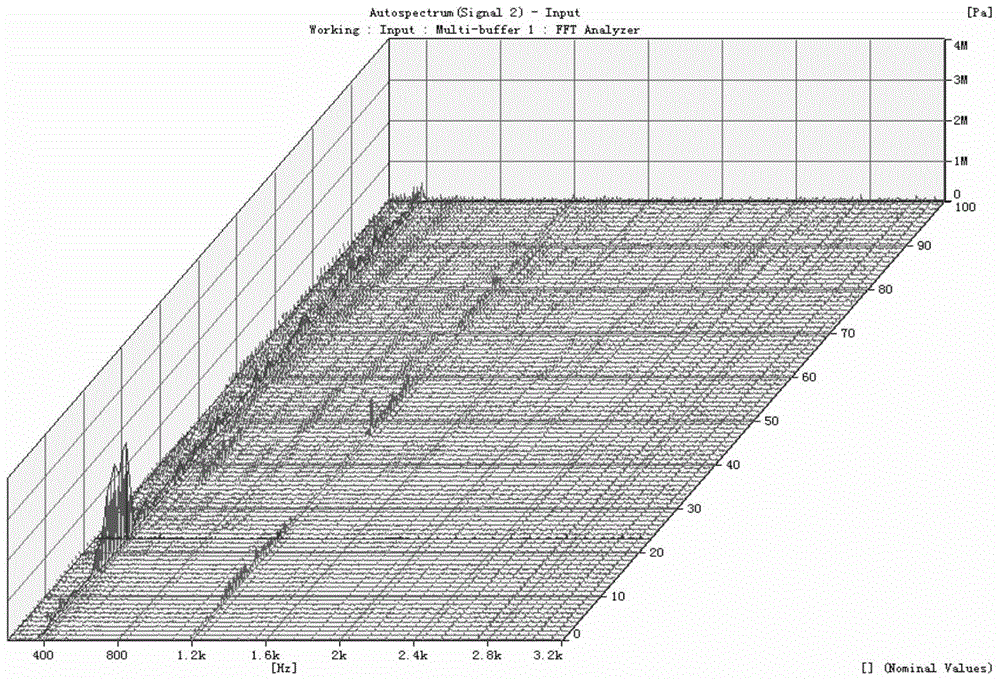

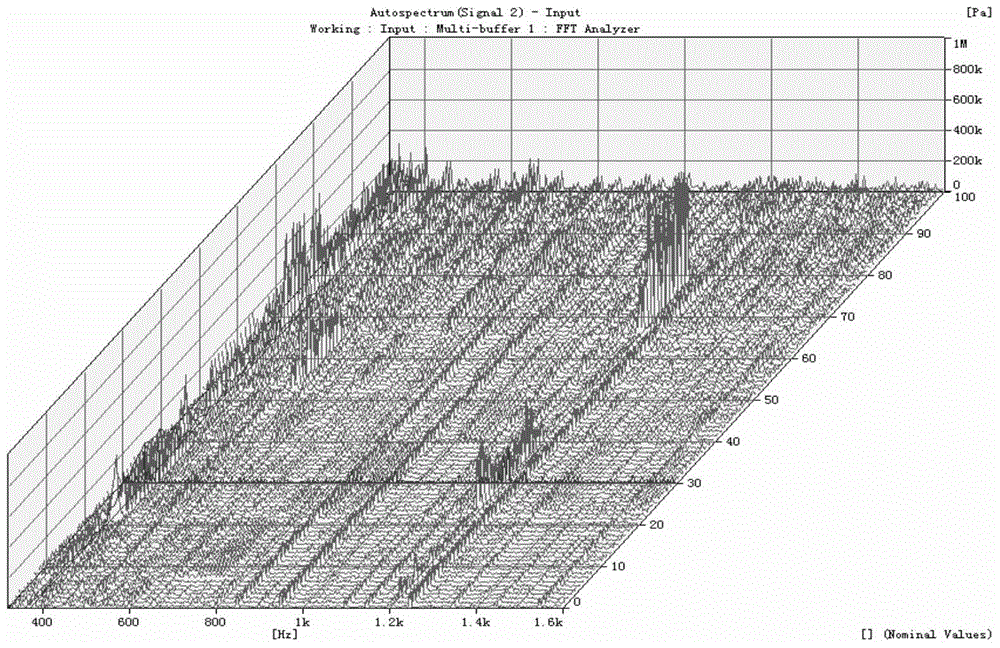

[0029] Determine the target order of optimization and the amount of constrained damping material used, and establish a topology optimization model for constrained damping blades:

[0030] find : x i , i = 1,2 . . . n ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com