645 mm last stage dynamic blade for industrial steam turbine

A technology for industrial steam turbines and moving blades, which is applied in the direction of machines/engines, blade support components, mechanical equipment, etc., can solve the problems of small exhaust area of final stage blades, large rotor size, high cost, etc., to achieve reduced vibration stress, good The effect of aerodynamic performance and convenient blade assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

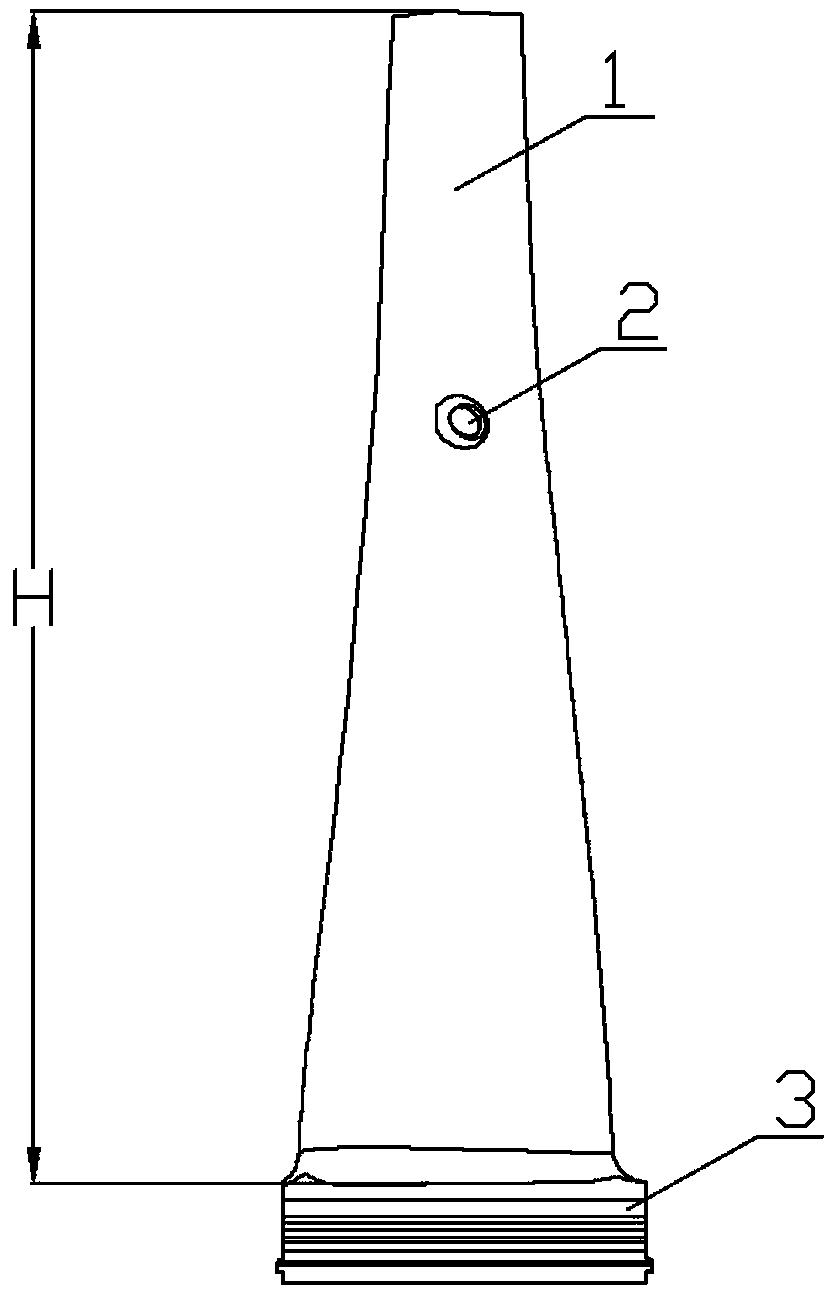

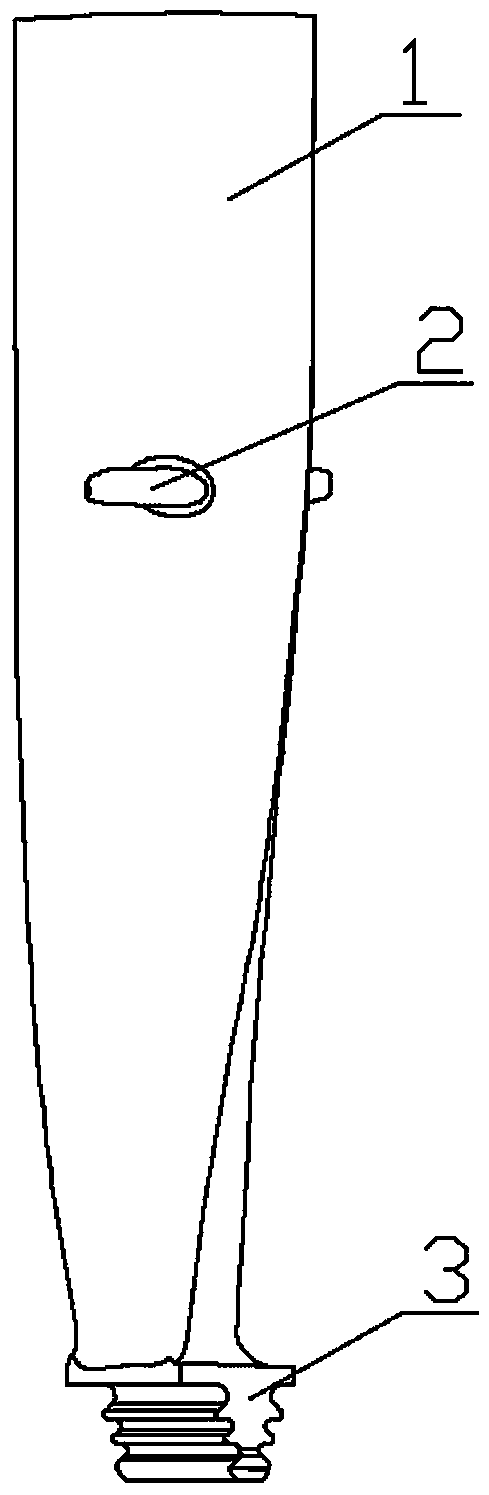

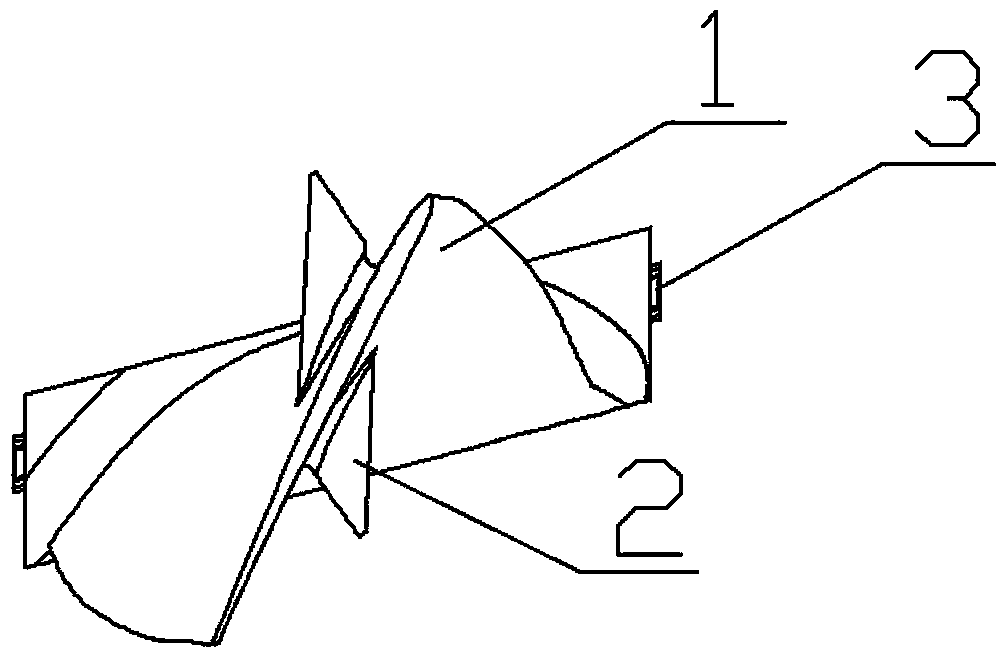

[0019] Such as figure 1 , 2 As shown in , 3, the 645mm final stage moving blade for the industrial steam turbine described in this embodiment is a twisted blade with variable cross-section, including blade body 1, blade root 3 and convex blades for forming a full circle of self-locking blades. Tailajin 2, the height of the blade body 1 is 645mm; the blade root 3 is a fir tree-shaped oblique blade root, the axial width of the blade root 3 is 200mm, and the blade is installed in the impeller groove through the fir tree-shaped blade root 3, Axially assembled; the boss is an elliptical boss, and the center of the boss is set at a height of 0.65 from the bottom to the top of the blade body; the blade body 1 has a hardened part at the back arc of the steam inlet side, and the hardened part is hardened. Length as needed.

[0020] The relative blade height Ld of the blade body 1 increases monotonously from 0% to 100%, and the pitch-to-chord length ratio T / b from the blade root secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com