Controller fault detection system of intelligent transmitter

An intelligent transmitter and fault detection technology, which is applied in the general control system, control/regulation system, test/monitoring control system, etc., can solve the problems of inaccurate transmitter control, difficult wiring, and technical difficulty. To achieve the effect of accurate and clear logic control, avoiding line connection and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

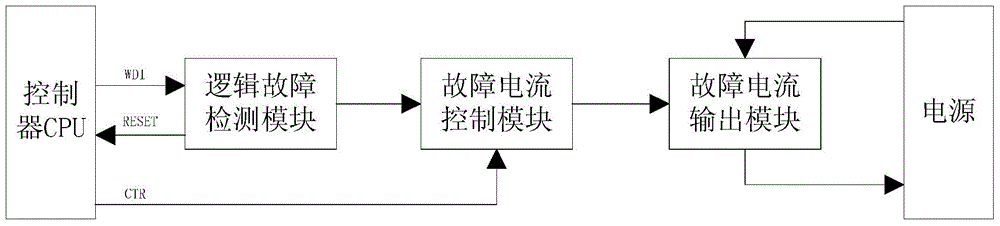

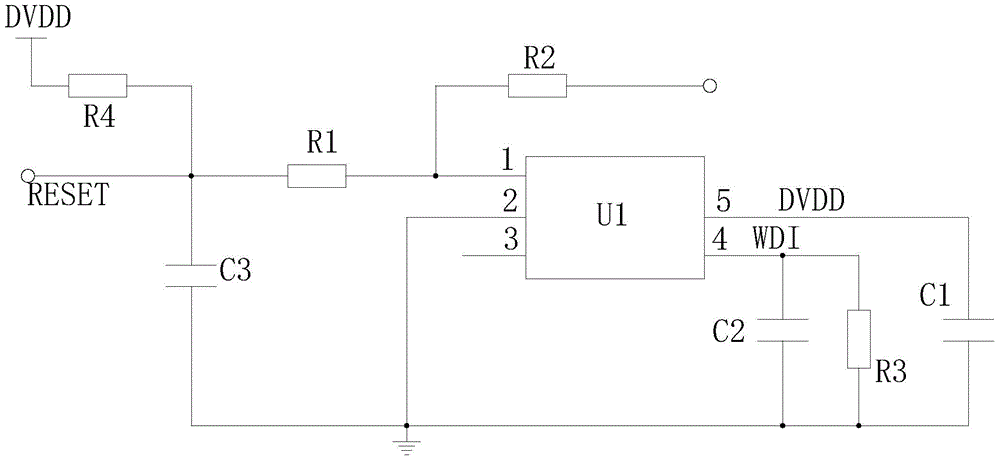

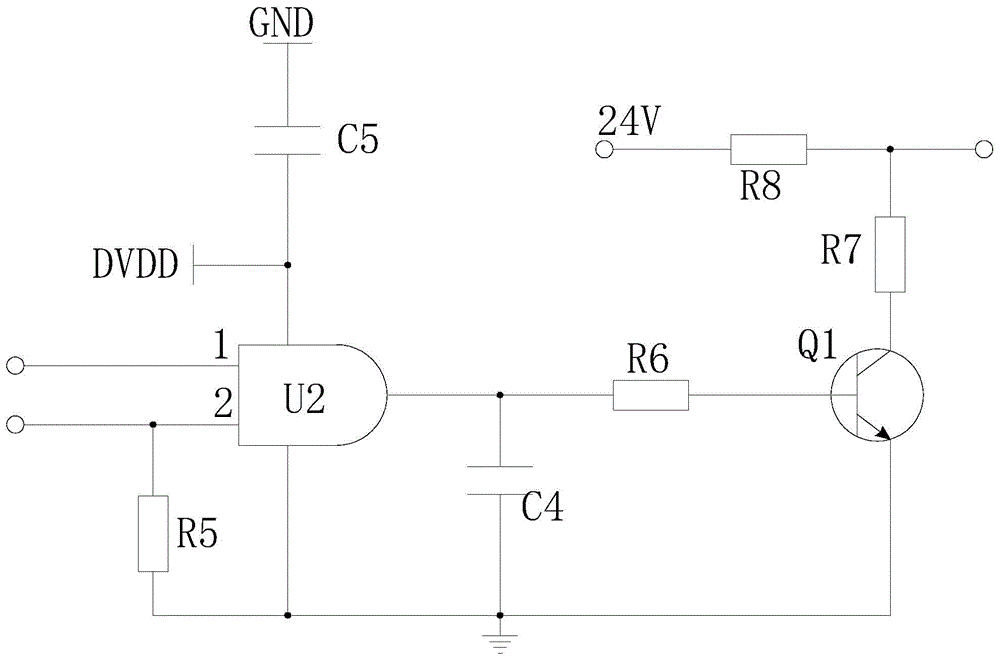

[0015] figure 1 It is a block diagram of the present invention, figure 2 It is the circuit diagram of the logical fault detection module of the present invention, image 3 It is the circuit diagram of the fault current control module of the present invention, Figure 4 It is a circuit diagram of the fault current output module of the present invention, as shown in the figure, the controller fault detection system of the intelligent transmitter provided by the present invention includes a logical fault detection module connected with the controller of the intelligent transmitter, and the A fault current control module connected to the logic fault detection module, a fault current output module connected to the fault current control module, and a power supply, the fault current control module is also connected to the controller, and the power supply terminal of the fault current output module is connected to the power supply; The controller failure detection system of the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com