Self-adaptive control system for main motor and auxiliary motor of straw briquetting machine

A technology of adaptive control and straw briquetting machine, which is applied in the direction of program control system, general control system, control/regulation system, etc. It can solve the problems of blockage of the body and affecting the briquetting machine, so as to increase the service life and save electric energy , Improve the effect of equipment production efficiency and intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

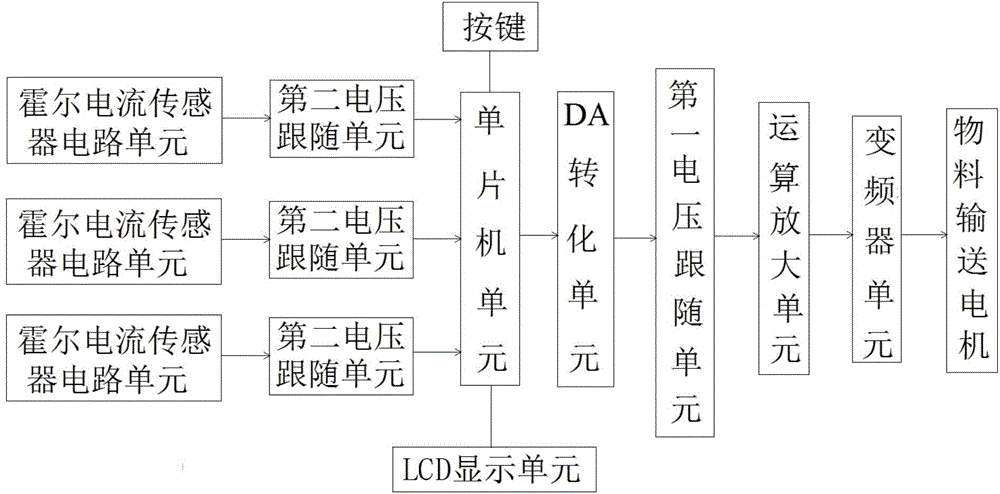

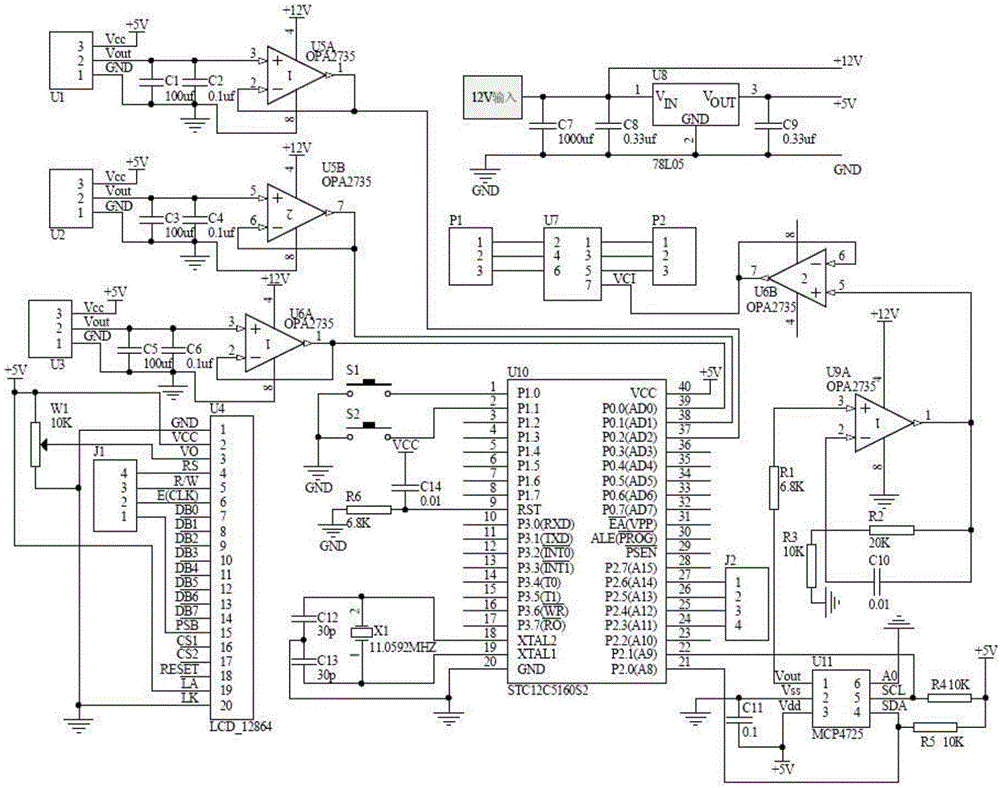

[0031] like figure 1 , 2 , an adaptive control system for main and auxiliary motors of a straw briquetting machine, comprising: a Hall current sensor circuit unit, a single-chip microcomputer unit, a DA conversion unit, a first voltage follower unit, an operational amplification unit, a frequency converter unit and an internal power supply unit ( figure 1 not shown in), the voltage output end of the Hall current sensor circuit unit is connected to the AD interface of the single-chip microcomputer unit, the single-chip microcomputer unit includes a single-chip microcomputer, the output end of the single-chip microcomputer is connected to a DA conversion unit, and the output end of the DA conversion unit is connected to the first The voltage follower unit, the operational amplifier unit and the frequency converter unit, the measured wire of the main motor of the pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com