Working condition simulation and pre-estimating method for service lifetime of rubber sealing element

A rubber seal and life-span technology, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve the problem of imprecise engineering value of permanent deformation critical value, cumbersome statistical analysis of empirical parameters, and uncertainty of rate of change of normal temperature state and other issues, to achieve the effect of rigorous and reliable evaluation results, scientific methods, and avoiding uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention is further described.

[0015] The daily storage temperature of the gas device is 20°C, and the technical index requires no leakage within 10 minutes at 0.40MPa. The connecting part of the device is sealed by an O-ring, and the sealing ring is made of silicon rubber. The service life of the sealing ring in the assembled state is estimated by testing.

[0016] Step 1, test condition selection and sample preparation.

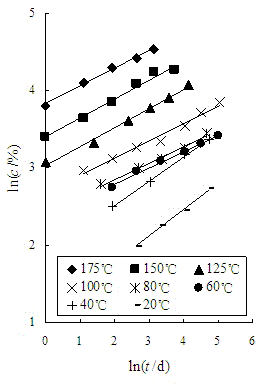

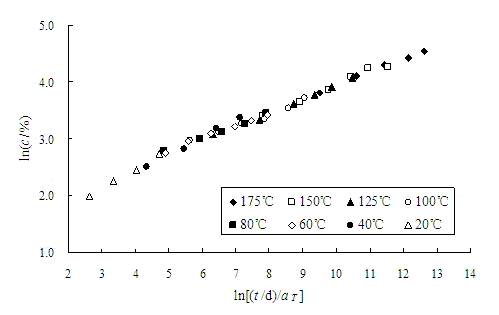

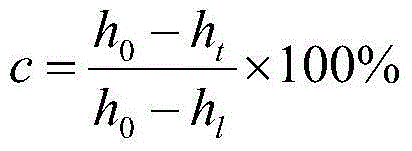

[0017] Select test conditions with reference to standards, including: test parameters, sample specifications, temperature values, test times, and sampling time intervals. The operation process is: refer to the standard, determine the compression rate of the material deformation test and the sample specification; determine the reference temperature according to the storage temperature requirements of the product at room temperature, and determine the acceleration temperature according to a certain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com