Multi-pass biomass pellet combustion technology and multi-pass biomass pellet combustion device

A biomass particle, multi-return technology, applied in the direction of combustion chamber, combustion method, combustion equipment, etc., can solve the problems of high concentration of flue gas and dust pollution environment, low utilization rate of biomass particles, insufficient combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

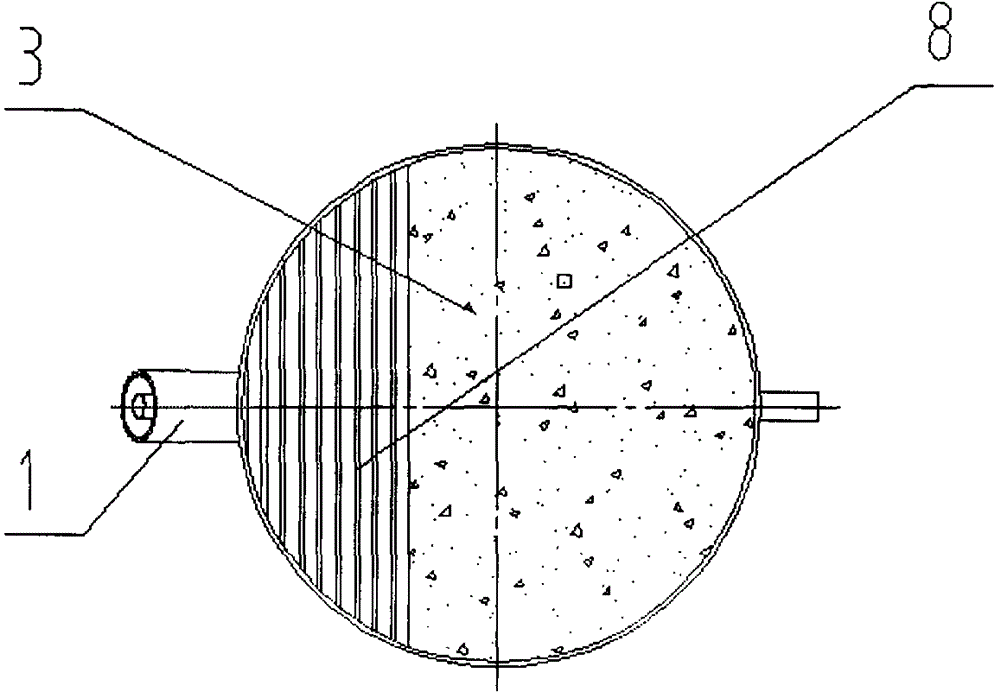

[0009] Referring to the accompanying drawings, the present invention includes: a feed inlet 1, a biomass burner liner 2, a first fire wall 3, a second fire wall 4, a third fire wall 5, a fire outlet 6, and a secondary air inlet 7. Fire grate 8, primary air inlet 9, igniter 10.

[0010] The feed inlet 1, the primary air inlet 9, the fire outlet 6, and the igniter 10 are all fixed on the inner tank wall of the biomass burner 2, and from bottom to top are the primary air inlet 9, the igniter 10, and the feed inlet 1 , the fire outlet 6, the secondary air inlet 7 is connected to the fire outlet 6, the grate 8 is fixed in the cavity of the inner tank 2 of the biomass burner, and is located between the feed inlet 1 and the primary air inlet 9, the first Fire-retaining wall 3, second fire-retaining wall 4, and third fire-retaining wall 5 are fixed in the inner tank 2 cavity of the biomass burner, located between the feed port 1 and the fire outlet 6, and are the first from bottom to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com