Building drainage plastic stack with spiral grooves

A technology for building drainage and spiral grooves, applied in the direction of pipes, rigid pipes, pipe components, etc., can solve problems such as damage to water seals, floor drain odor, and noise increase, to avoid damage to water seals, prevent odor, and prevent pipeline vibration. and drainage noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

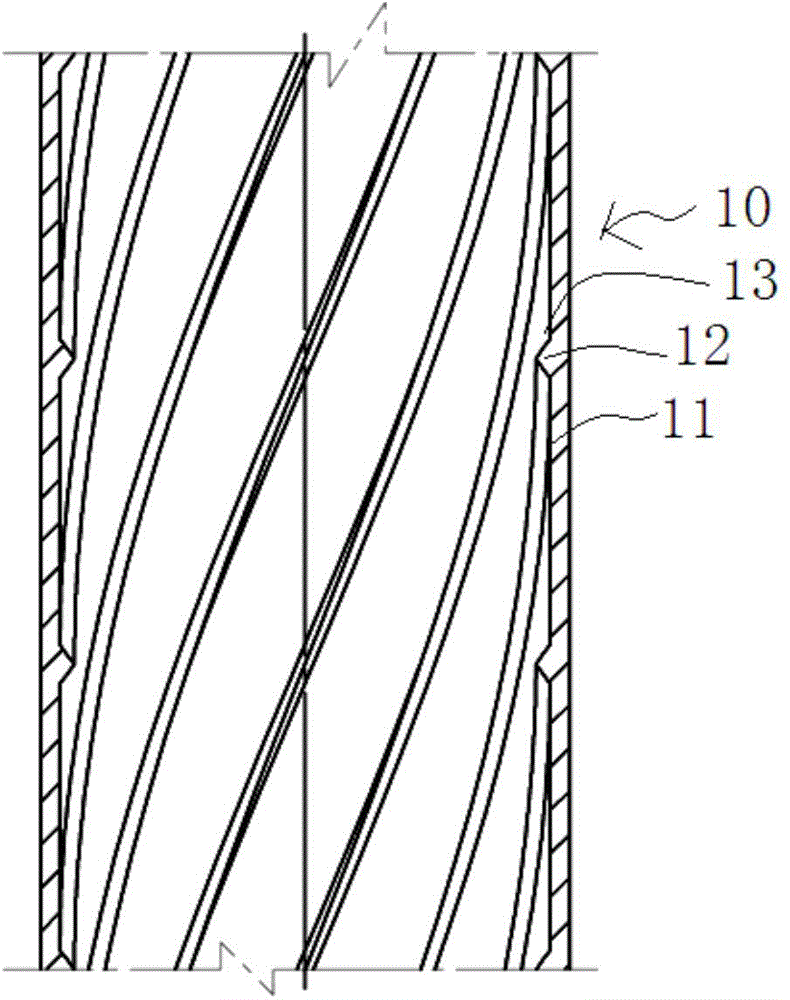

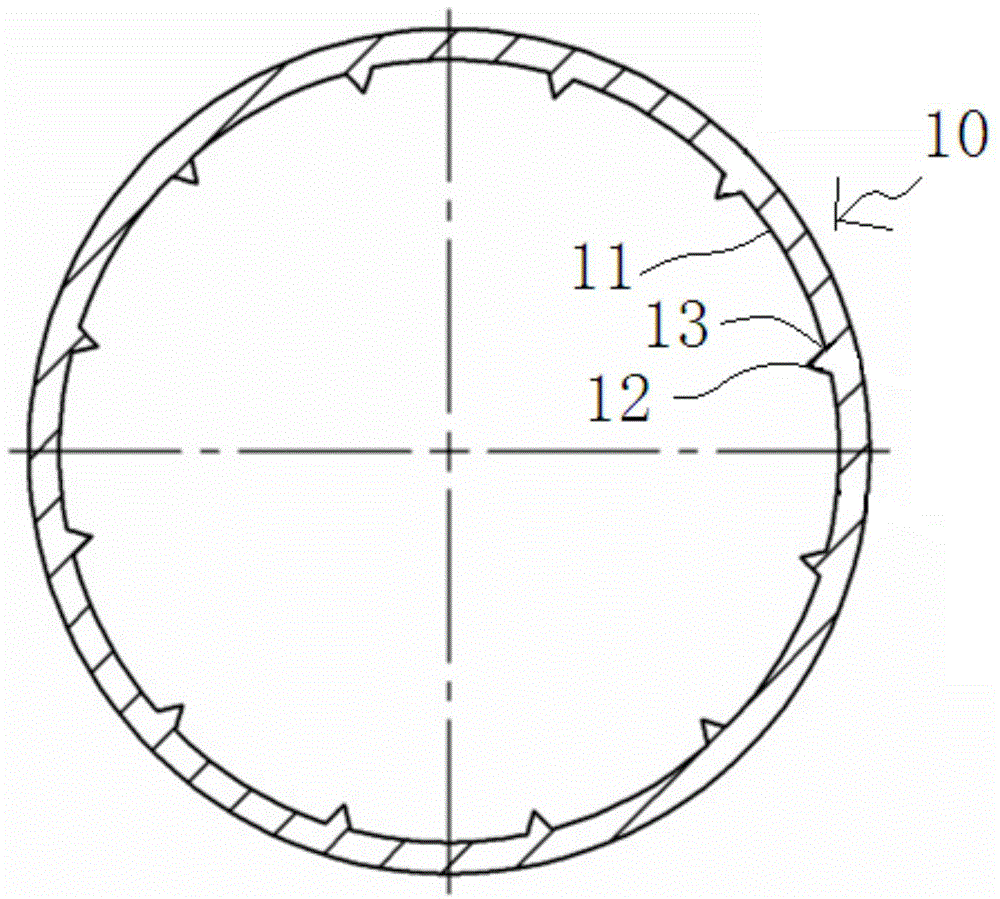

[0027] see Figure 5 to Figure 8 The shown building drainage plastic riser with spiral grooves includes a plastic riser body 100, and a number of spiral grooves 120 are coaxially and circumferentially arranged on the inner wall 110 of the plastic riser body 100 along the axial direction of the riser.

[0028] In this embodiment, there are twelve spiral grooves 120, which are equally divided along the circumferential direction of the pipe section. The junction 121a between the groove bottom 121 of the spiral groove 120 and the groove wall and the junction 122 between the notch of the spiral groove 120 and the inner wall 110 of the plastic riser body are arc transition structures. In this embodiment, the groove bottom 121 of the spiral groove 120 is a concave arc surface, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com