Wedge claw type stepless variable-speed mechanism and transmission system

A technology of continuously variable speed change mechanism and speed change mechanism, which is applied in transmission devices, friction transmission devices, mechanical equipment, etc., can solve the problems of high noise, large volume, and easy loss of transmission parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

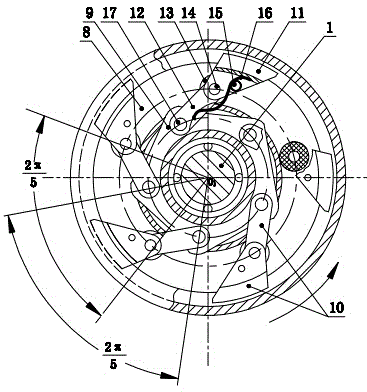

[0042] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0043] See attached Figures 1 to 7 , the wedge-claw type continuously variable transmission mechanism in the figure includes a fixed central shaft 1; where:

[0044] There is a square shaft section on the fixed central shaft 1, and a rectangular slider frame 4 is set on the square shaft section, and the rectangular slider frame 4 slides up and down at the square shaft section under the action of an external force; the rectangular slider frame 4 The outer cover is equipped with a square hole frame plate 5, and the square hole frame plate 5 slides left and right outside the rectangular slider frame 4 under the action of external force; a small eccentric sleeve 2 is set on the fixed central axis 1 close to the power input end 19 of the square shaft section The small eccentric sleeve 2 is covered with a large eccentric sleeve 3 matching the small eccentric slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com