Pipeline coupling detection device

A detection device and pipeline technology, which is applied in the direction of construction, can solve the problems of inability to achieve accurate guidance in well logging operations, misjudgment of pipeline couplings, etc., and achieve the effect of avoiding misjudgment of pipeline couplings and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The core of the present invention is to provide a pipeline coupling detection device, so as to avoid misjudgment of the position of the pipeline coupling due to the sloshing of the pipeline, and improve the accuracy of pipeline coupling detection.

[0023] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

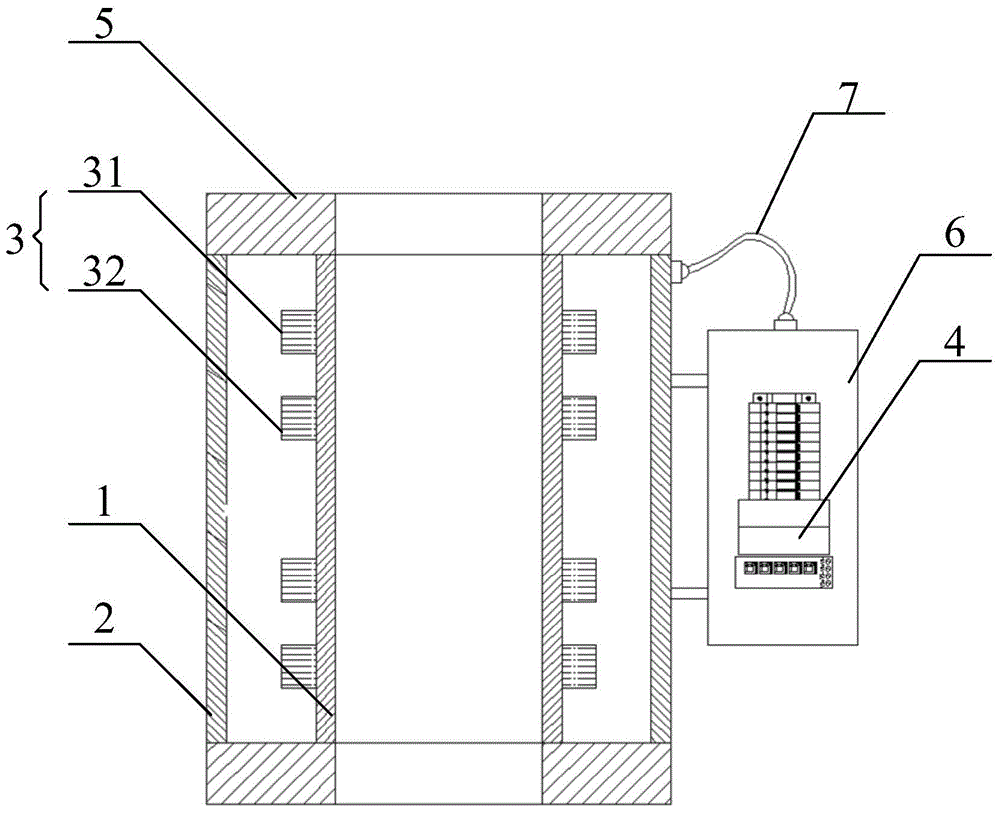

[0024] Please also refer to figure 1 , figure 1 It is a structural schematic diagram of a pipeline coupling detection device disclosed in an embodiment of the present invention.

[0025] The pipeline coupling detection device provided by the embodiment of the present invention is mainly used in the oil pipe lifting operation in the workover or logging process. The pipeline coupling detection device includes an inner layer pipe 1 and an outer layer pipe 2. The inner layer pipe 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com