Non-contact type high-accuracy array electromagnetic thickness gauge

An electromagnetic thickness gauge, non-contact technology, applied in electromagnetic measuring devices, using electromagnetic means, electric/magnetic thickness measurement, etc., can solve problems such as easy to get stuck, inconvenient logging, poor stability, etc., and achieve maximum use Flexibility, not easy to get stuck, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

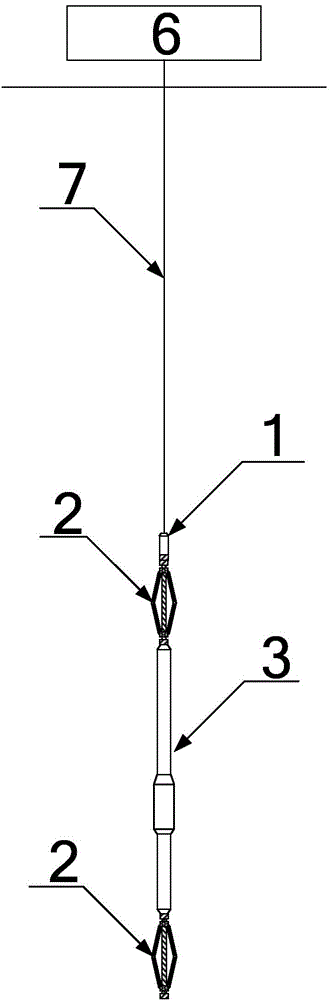

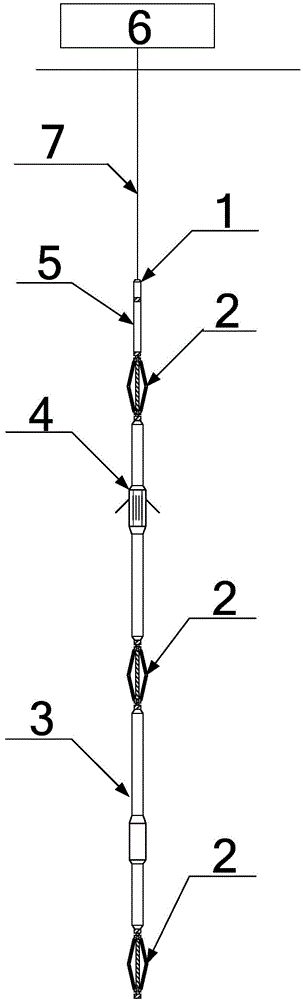

[0038] see figure 1 as well as figure 2 , is a typical logging hook-up diagram of a non-contact high-precision electromagnetic thickness gauge, when logging alone (such as figure 1 shown) mainly includes ground equipment 6, logging cable 7, cable head 1, two centralizers 2 and electromagnetic thickness gauge 3; and electromagnetic thickness gauge 3 and multi-arm caliper 4 are connected to form an instrument string, and the When combined logging (such as figure 2 shown), mainly includes ground equipment 6, logging cable 7, cable head 1, telemeter 5, three centralizers 2, multi-arm caliper 4 and electromagnetic thickness gauge 3, ground equipment 6 mainly includes cable car, Ground decoding platform and logging computer, etc.

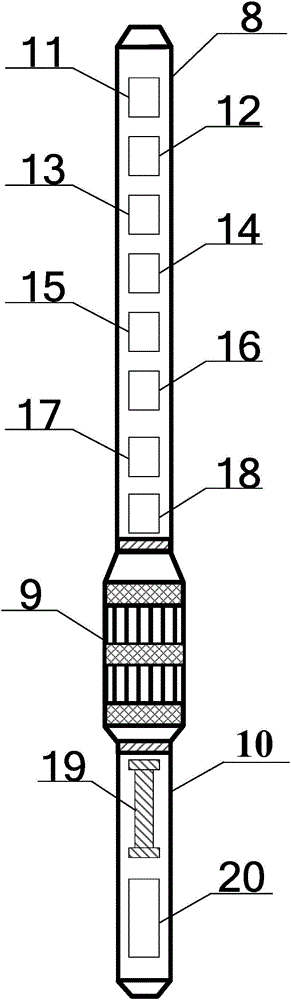

[0039] see image 3 as well as Figure 7, is a schematic diagram of a typical structure of a non-contact high-precision electromagnetic thickness gauge. The instrument is composed of the electronic sub-section 8 of the electromagnetic thickness ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com