Toilet bowl control system and method

A flush toilet and control system technology, applied in the field of flush toilets, can solve the problems that the sewage discharge efficiency cannot reach a stable and optimal state, the flow rate is low, and cannot be maintained, so as to improve the sewage discharge efficiency, and the sewage discharge efficiency is stable and good. washout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0049] The invention provides a control system and method for a flush toilet.

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

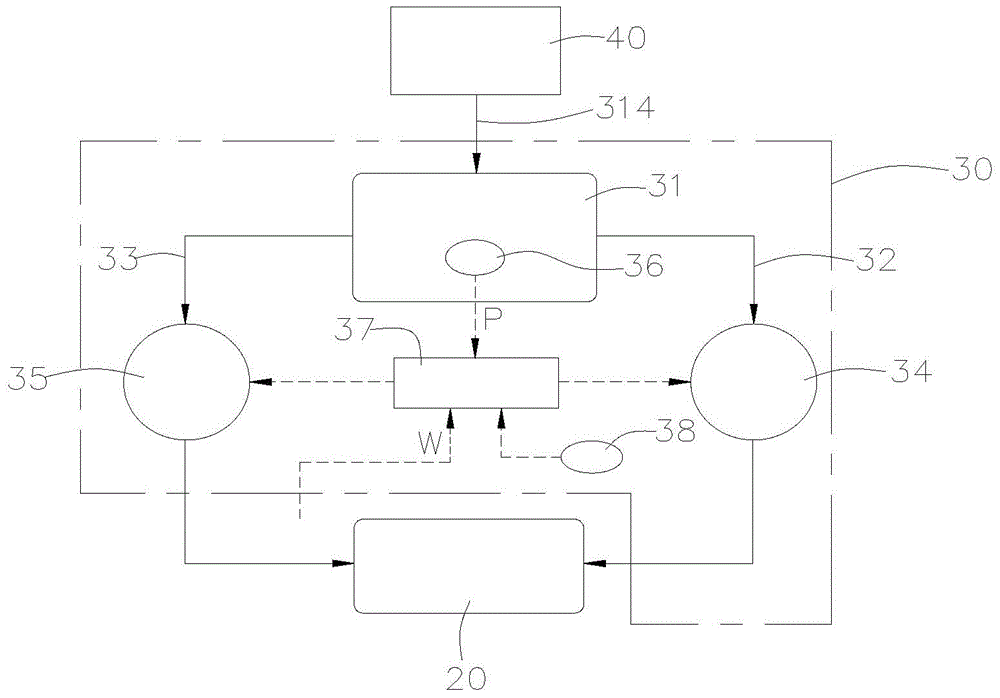

[0051] Such as figure 2 , 3 As shown, the present invention provides a preferred embodiment of a control system for a flush toilet. The toilet 20 has a water ring flush channel 21 and a nozzle flush channel 22; the control system 30 mainly includes a pressure reducing valve 31, a The water ring water supply pipeline 32, a jet outlet water supply pipeline 33, a water circle solenoid valve 34, a jet outlet solenoid valve 35, a water pressure sensor 36 and a contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com