Jointing channel dredging device

A channel dredging and grafting technology, applied in the field of graftable channel dredging devices, can solve problems such as difficult work of large excavators, and achieve the effects of wide market space, flexible excavation, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

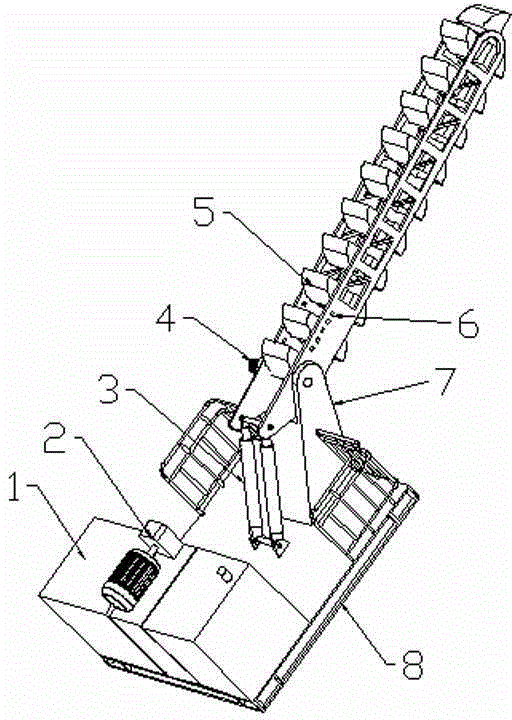

[0013] The graftable waterway dredging device includes a fuel tank 1, a hydraulic pump station 2, a hydraulic cylinder 3, a hydraulic motor 4, a dump bucket 5, a support arm 6, a turret 7 and a base 8, and is characterized in that: the base 8 is installed There are oil tank 1, hydraulic cylinder 3 and turret 7. Hydraulic pump station 2 is installed on oil tank 1. Hydraulic pump station 2 is connected with hydraulic cylinder 3 and hydraulic motor 4 through pipelines to provide power. The turret 7 passes through the rotating shaft A support arm 6 is installed to realize the up and down rotation of the support arm 6; multiple dump buckets 5 are installed on the support arm 6 through belts, and the rotation of the dump bucket 5 drives the silt in the river to be slowly pulled up, and then put into the matching loading ship next to it The belt is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com