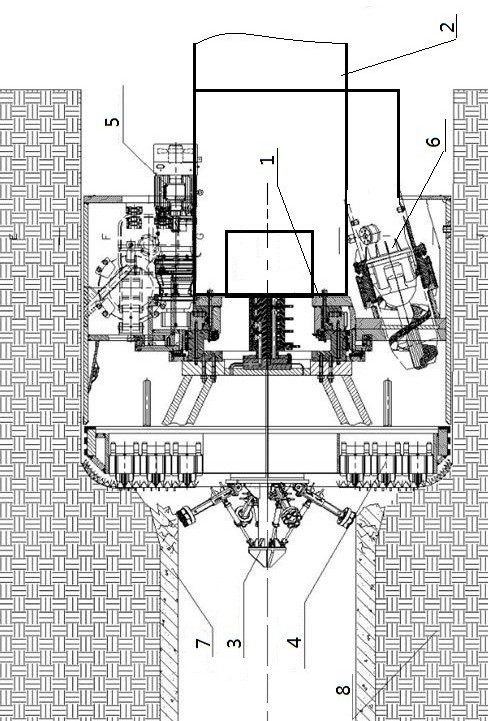

A kind of demolition, diameter expansion roadheader and its construction method

A technology of roadheader and demolition, which is applied in the field of pipeline expansion and excavation, can solve the problems of low efficiency of pipeline demolition, expansion and excavation, and achieve the effect of wide application range, good integration and efficient excavation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

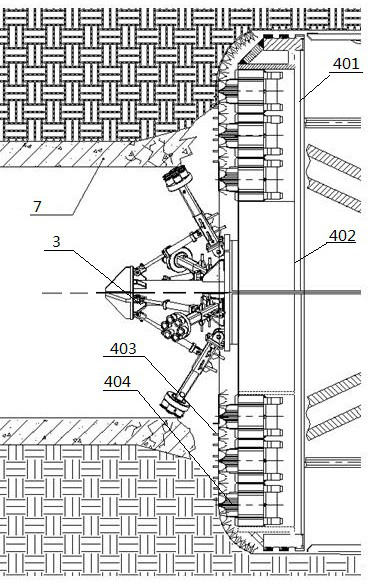

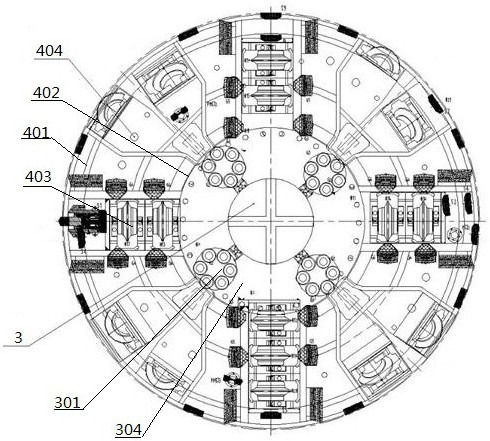

[0037] Embodiment 3: a kind of demolition as described in embodiment 2, the construction method of expanding diameter boring machine, the steps are as follows:

[0038] S1: Hoist the demolition and expansion boring machine to the original pipeline, and debug it to the ready-to-work state;

[0039] S2: Start the demolition and diameter-expanding roadheading machine, the pipeline rescue device 3 of the demolition and diameter-expanding roadheader first demolishes the original pipeline, and the 4 pairs of expanding cutterheads of the demolition and diameter-expanding roadheader are demolished The tunnel is expanded. The details are as follows: S2.1: Adjust the extension length and opening angle of the suspension cutting arm 301 of the pipeline breaking device 3 according to the diameter of the original pipeline, so as to ensure that the suspension cutting hob 3013 on the suspension cutting arm 301 has a suitable suspension with the original pipeline. Cutting angle, the original ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com