Electrophoretic coating water blowing method and water blowing device

An electrophoretic coating and water blowing technology, applied in electrolytic coatings, electrophoretic plating, coatings, etc., can solve the problems of poor working environment, high labor cost, and low work efficiency for operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below, but the present invention is not limited to the following examples.

[0034] A water blowing method for electrophoretic coating provided by the invention comprises the following steps:

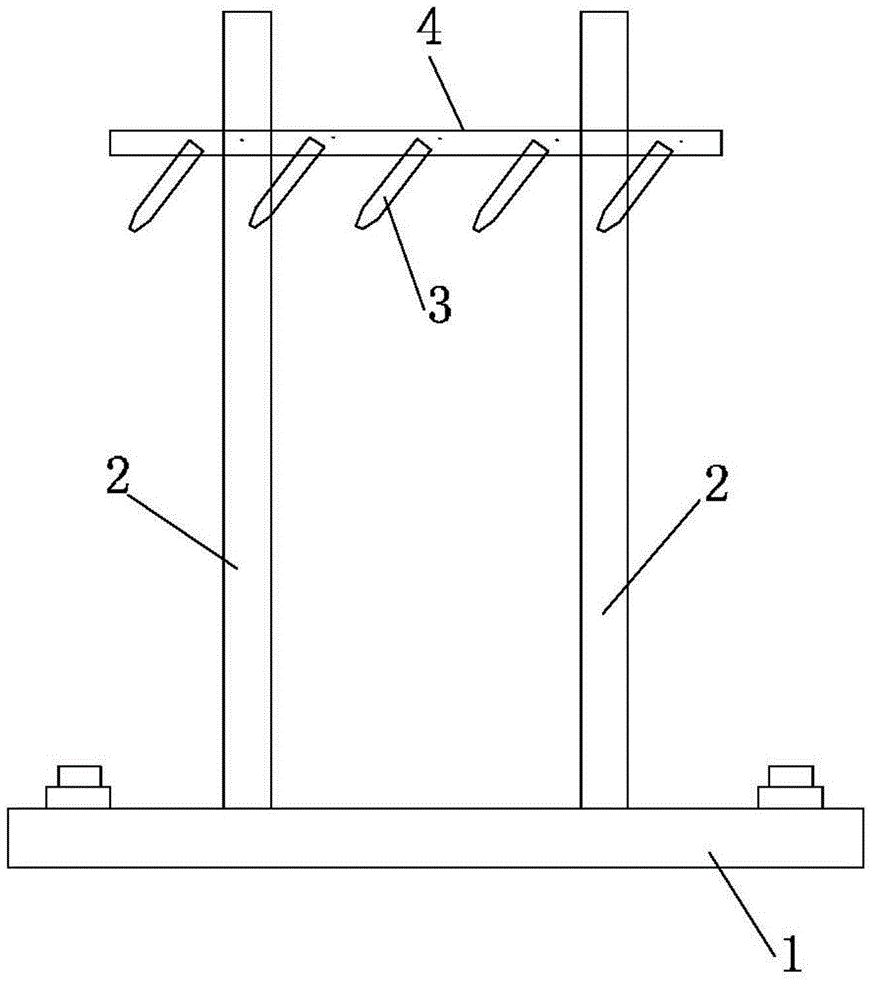

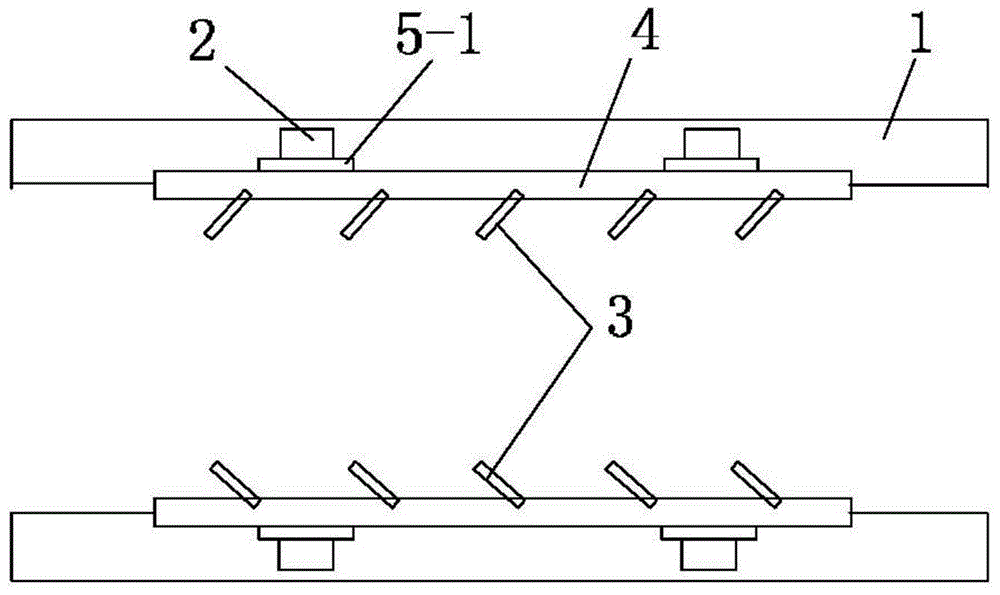

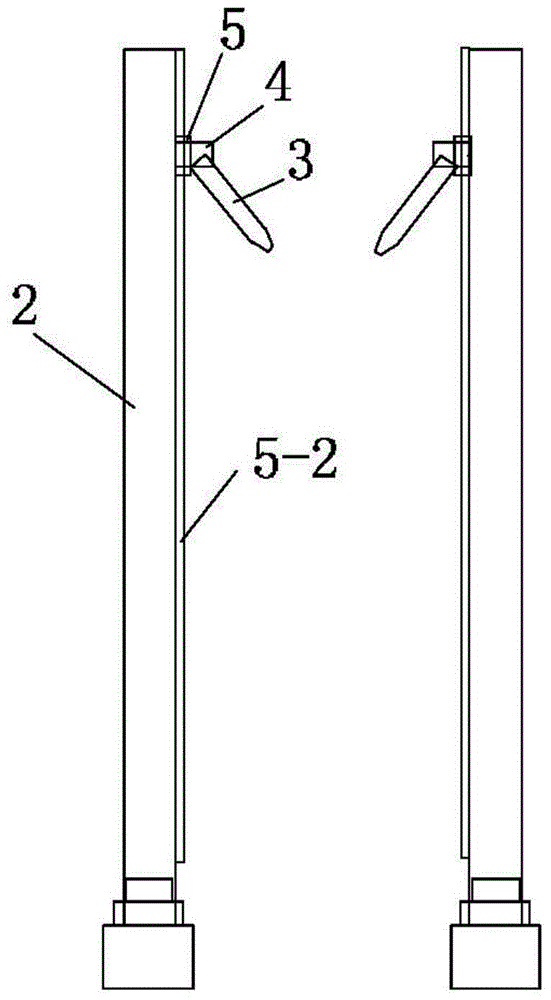

[0035] 1) Blowing: on at least one side of the painted piece, a number of airflows are sprayed from the nozzle 3 arranged obliquely downward, and the water on the surface of the painted piece is blown off;

[0036] 2) Sweeping: move the nozzle back and forth in the horizontal direction, and at the same time reciprocate in the vertical direction, so that the air flow will be displaced in both the horizontal direction and the vertical direction, and the water on the surface of the coating will be completely dried.

[0037] Both sides of the coating piece are sprayed with several streams of airflow from obliquely downwardly arranged nozzles, and the airflows on both sides are distributed symmetrically.

[0038] The water blowing devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com