A kind of preparation method of high softening point asphalt

A high softening point asphalt and softening point technology, which is applied in the processing of tar pitch/petroleum pitch/natural pitch and the petroleum industry, etc., can solve problems such as complex process, long production cycle, and difficult operation, and achieve good compatibility, Effect of increasing energy consumption and increasing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

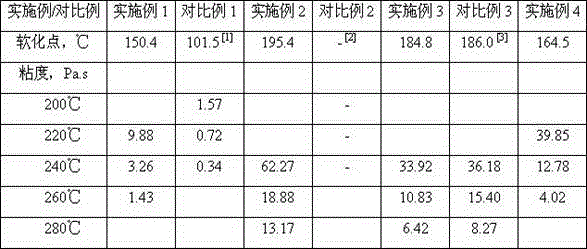

[0028] Take 120g rock asphalt (softening point is 212°C) and 100g kerosene in a container, stir at room temperature (25°C) for 20 minutes, and prepare the mother liquor after fully mixing. Put 80g of vacuum residue with a penetration of 82 1 / 10mm (softening point is 44.6°C) in a blending tank and heat it to a molten state of 140°C. Add the mother liquor and feed compressed air, adjust the pressure reducing valve so that the gas inlet pressure of the blending tank is 0.15 MPa, keep the temperature of the blending tank at 190°C, stir for 100 minutes, then raise the temperature to 220°C, and stir for 30 minutes to obtain a high softening point asphalt product . The product properties are shown in Table 1.

Embodiment 2

[0032] Take 160g of rock asphalt (softening point is 226°C) and 150g of diesel oil in a container, stir at 60°C for 15 minutes, and prepare the mother liquor after fully mixing. Put 40g of vacuum residue with a penetration of 45 1 / 10mm (softening point: 47.8°C) in a blending tank and heat to a molten state of 150°C. Add mother liquor into the blending tank and feed compressed nitrogen, adjust the pressure reducing valve so that the gas inlet pressure of the blending tank is 0.22 MPa, keep the temperature of the blending tank at 210°C, stir for 90 minutes, then raise the temperature to 270°C, and stir for 25 minutes to obtain high Softening point bituminous products. The product properties are shown in Table 1.

Embodiment 3

[0036] Take 150g of rock asphalt (softening point is 226°C) and 130g of diesel oil in a container, stir at 50°C for 10 minutes, and mix thoroughly to obtain the mother liquor. Put 50g of vacuum residue (softening point: 46.2°C) with a penetration of 58 1 / 10mm into a blending tank and heat it to a molten state of 150°C. Add mother liquor into the blending tank and feed compressed air, adjust the pressure reducing valve so that the gas inlet pressure of the blending tank is 0.20 MPa, keep the temperature of the blending tank at 200°C, and stir for 85 minutes. The temperature of the mixing tank was raised to 260° C. and kept for 25 minutes. The process conditions and product properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com