Microporous polylactic acid oriented film

A technology of oriented film and polylactic acid, which is applied in the field of polymer materials and can solve problems such as the difficulty in making microporous films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10、 comparative example 1~2

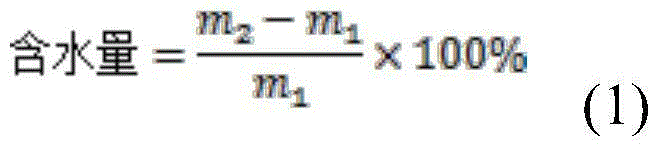

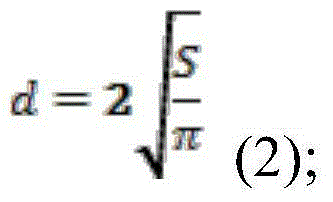

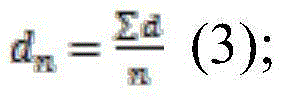

[0093] According to the proportion listed in Table 1, use a twin-screw extruder to extrude and granulate, and the extrusion temperature is 180-200°C. Next, an unoriented film with a thickness of 100 μm was prepared by blow molding through a single-screw extruder. The blow molding temperature is 180-200°C. Furthermore, in hot air at 80°C, the unoriented film was simultaneously biaxially stretched 3×3 times, and then various performance tests were performed on the obtained film, and the results are listed in Table 1.

Embodiment 11~20、 comparative example 3~4

[0095] According to the proportion listed in Table 2, use a twin-screw extruder to extrude and granulate, and the extrusion temperature is 180-200°C. Next, an unoriented film with a thickness of 100 μm was prepared by blow molding through a single-screw extruder. The blow molding temperature is 180-200°C. Furthermore, in water at 80°C, the unoriented film was simultaneously biaxially stretched 3×3 times, and then various performance tests were performed on the obtained film, and the results are listed in Table 2.

Embodiment 21-27

[0097] According to the proportioning of Example 8, a twin-screw extruder is used to extrude and granulate, and the extrusion temperature is 180-200°C. Next, a non-oriented film with a thickness of 100 μm was prepared by single-screw extrusion casting at a casting temperature of 180-220° C. Furthermore, according to the conditions shown in Table 3, the unoriented film was uniaxially or biaxially stretched in hot water. Then, various performance tests were carried out on the obtained film, and the results are listed in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com