Preparation method of 4-amino-6-(trichloroethenyl)-1, 3-benzene disulfonamide

A technology of trichlorovinyl and benzenedisulfonamide, which is applied in the preparation of 4-amino-6--(trichloroethenyl)-1,3-benzenedisulfonamide and the field of preparation of veterinary drugs, which can solve the problem of low synthesis efficiency , long cycle and other issues to achieve the effect of speeding up the process and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

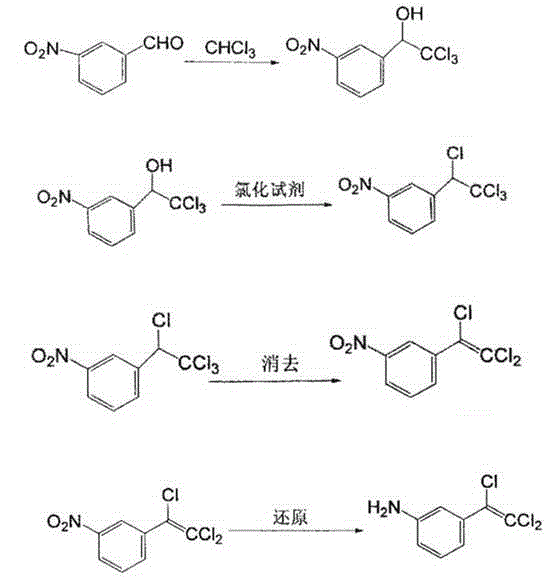

Method used

Image

Examples

Embodiment 1

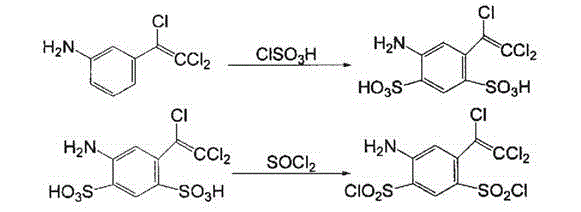

[0015] Put 30g of m-nitrobenzaldehyde and 15ml of chloroform in 120ml of DMF, cool to -10~-20°C, dissolve 0.9g of cesium carbonate in 20ml of methanol, add dropwise under nitrogen, and keep at -15~-20°C for 2 -3 hours transferred to 200mL toluene and 20mL30% hydrochloric acid solution, the water layer was separated, the organic layer was washed with water, and the water layer was separated; the organic layer was washed with sodium bicarbonate, purified, and then dried to obtain a condensate with a yield of 88 %; After the condensate is chlorinated and eliminated, 50g of the eliminated product is made of methanol-water as a solvent and iron is used as a reducing agent under acidic conditions, and 0.25g of iridium complex [Cp*IrCl 2 ] 2 As a catalyst, a dark red liquid is obtained through reduction reaction at room temperature, with a yield of 92%. Finally, the reduced product is sulfonated with chlorosulfonic acid, ammonified, and purified to obtain 4-amino-6--(trichloroethenyl...

Embodiment 2

[0017] Put 30g of m-nitrobenzaldehyde and 15ml of chloroform in 120ml of DMF, cool to -10~-20°C, dissolve 1.5g of cesium carbonate in 20ml of methanol, add dropwise under nitrogen, and keep at -15~-20°C for 2 -3 hours transferred to 200mL toluene and 20mL30% hydrochloric acid solution, the water layer was separated, the organic layer was washed with water, and the water layer was separated; the organic layer was washed with sodium bicarbonate, purified, and then dried to obtain a condensate with a yield of 90 %; After the condensate is chlorinated and eliminated, 50g of the eliminated product is made of methanol-water as a solvent and iron is used as a reducing agent under acidic conditions, and 0.5g of iridium complex [Cp*IrCl 2 ] 2 As a catalyst, a dark red liquid can be obtained through reduction reaction at room temperature, with a yield of 96%. Finally, the reduced product can be sulfonated with chlorosulfonic acid, ammonified, and purified to obtain 4-amino-6--(trichloro...

Embodiment 3

[0019] Put 30g of m-nitrobenzaldehyde and 15ml of chloroform in 120ml of DMF, cool to -10~-20°C, dissolve 1.2g of cesium carbonate in 20ml of methanol, add dropwise under nitrogen, and keep at -15~-20°C for 2 -3 hours transferred to 200mL toluene and 20mL30% hydrochloric acid solution, the water layer was separated, the organic layer was washed with water, and the water layer was separated; the organic layer was washed with sodium bicarbonate, purified, and then dried to obtain a condensate with a yield of 89% %; After the condensate is chlorinated and eliminated, 50g of the eliminated product is made of methanol-water as a solvent and iron is used as a reducing agent under acidic conditions, and 0.4g of iridium complex [Cp*IrCl 2 ] 2 As a catalyst, a deep red liquid can be obtained through reduction reaction at room temperature, with a yield of 90%. Finally, the reduced product can be sulfonated with chlorosulfonic acid, ammonified, and purified to obtain 4-amino-6--(trichlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com