Method for producing p-xylene employing diverse raw materials

A technology for p-xylene and xylene, which is applied in the field of diversifying raw materials to produce p-xylene, can solve the problems of single raw material source components, poor flexibility in raw material adjustment, etc., and achieves the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] With light cycle pyrolysis oil and naphtha as fresh raw materials, the composition of raw materials is shown in Table 1.

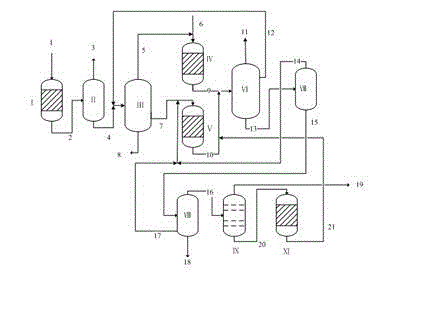

[0021] Process flow like figure 1 As shown, 40t / h of fresh light cycle pyrolysis oil feedstock enters the selective hydrocracking unit reaction, and the reaction product separates light components and enters the raw material pre-separation unit, where C5-C6 components, C7-C10 components, and C11+ are sequentially separated Components. Among them, the C5-C6 components are used as the reaction raw materials and the fresh naphtha raw materials 60t / h enter the reforming unit for reaction. The C7-C10 components and the C7 components from the toluene tower top cycle and the side line of the heavy aromatics tower produce C9-C10 groups. And enter the transalkylation unit together. The products of the reforming unit and the transalkylation unit enter the product separation unit together to separate C1-C4 light components, C5-C6 components and C7+ components. ...

Embodiment 2

[0030] With light cycle pyrolysis oil and naphtha as fresh raw materials, the composition of raw materials is shown in Table 1.

[0031] Process flow like figure 1 As shown, 50t / h of fresh light cycle pyrolysis oil feedstock enters the selective hydrocracking unit for reaction, and the reaction product separates the light components and then enters the feedstock pre-separation unit, where C5-C6 components, C7-C10 components and C11+ are sequentially separated Components. Among them, C5-C6 components are used as reaction raw materials to enter the reforming unit together with fresh naphtha raw materials 55t / h. C7-C10 components and C7 components from the toluene tower top cycle and C9-C10 groups are produced from the side line of the heavy aromatics tower. And enter the transalkylation unit together. The products of the reforming unit and the transalkylation unit enter the product separation unit together to separate C1-C4 light components, C5-C6 components and C7+ components. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com