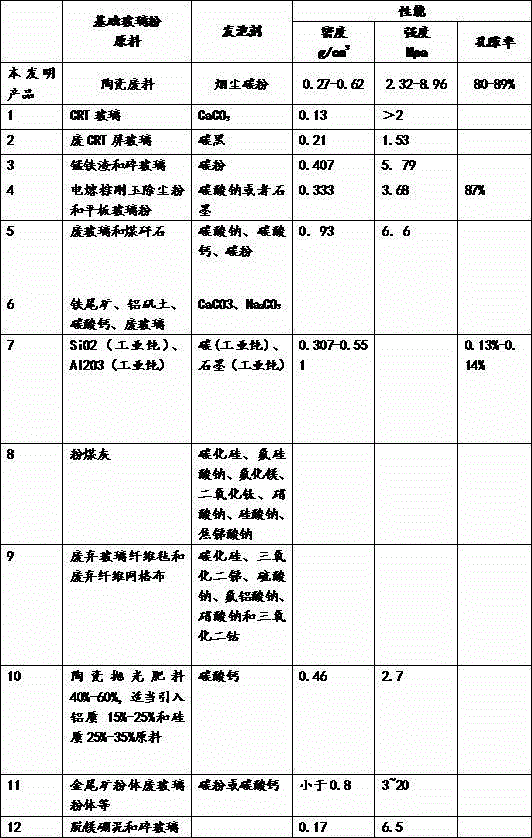

Method for preparing foam thermal-insulation construction material by using smoke dust carbon powder as foaming agent

A soot toner and foaming agent technology, which is applied in applications, ceramic products, household appliances, etc., can solve the problems of consuming manpower and material resources, polluting underground water quality, occupying land, etc., achieving low production costs, good promotion and use value, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

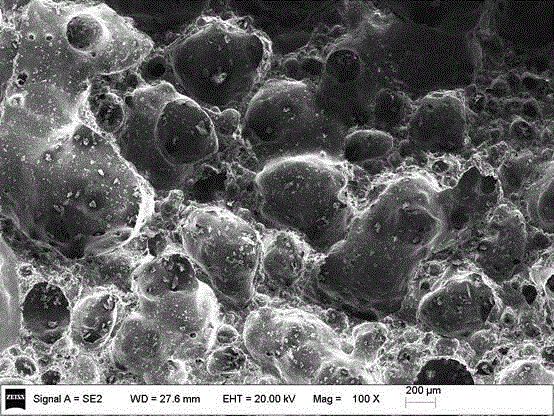

Image

Examples

Embodiment 1

[0027] The technical solution adopted by the present invention is a method for preparing foam insulation building materials using soot carbon powder as a foaming agent. The steps of the method include:

[0028] (1) Mixture treatment: Weigh the soot toner foaming agent, raw materials, flux, and foam stabilizer according to the mass percentage of the mixture, add them to a ball mill tank to obtain the mixture, and then carry out dry pressing molding of the mixture. The formed blank is put into the mould;

[0029] In this step, the mass percentages of each component in the mixture are: 3% ball-milled soot carbon powder foaming agent, 85% ball-milled raw materials, 9% flux, and 3% foam stabilizer. The raw material is waste glass. The flux is borax; the foam stabilizer is sodium phosphate. The particle size of the mixture obtained after ball milling in the ball mill tank is less than 200 mesh. Ensure the smaller particle size, so as to ensure the uniformity and product performan...

Embodiment 2

[0038] On the basis of Example 1, this example is a method for preparing a foam insulation building material using soot carbon powder as a foaming agent. The steps of the method include:

[0039](1) Mixture treatment: Weigh the soot toner foaming agent, raw materials, fluxing agent, and foam stabilizer according to the mass percentage of the mixture, add them into a ball mill tank to obtain the mixture, and then carry out dry pressing molding of the mixture. The formed blank is put into the mould;

[0040] In this step, the mass percentages of each component in the mixture are: 2% ball-milled soot carbon powder foaming agent, 80% ball-milled raw materials, 16% flux, and 2% foam stabilizer. The raw material is fly ash. The flux is borax; the foam stabilizer is sodium phosphate. The particle size of the mixture obtained after ball milling in the ball mill tank is less than 200 mesh.

[0041] (2) Treatment in the preheating stage: the resistance furnace is heated to 200 ℃ at a...

Embodiment 3

[0048] On the basis of Example 1, this example is a method for preparing a foam insulation building material using soot carbon powder as a foaming agent. The steps of the method include:

[0049] (1) Mixture treatment: Weigh the soot toner foaming agent, raw materials, fluxing agent, and foam stabilizer according to the mass percentage of the mixture, add them into a ball mill tank to obtain the mixture, and then carry out dry pressing molding of the mixture. The formed blank is put into the mould;

[0050] In this step, the mass percentages of each component in the mixture are: 4% ball-milled soot carbon powder foaming agent, 75% ball-milled raw materials, 16% flux, and 5% foam stabilizer. The raw material is fly ash. The flux is borax; the foam stabilizer is sodium phosphate. The particle size of the mixture obtained after ball milling in the ball mill tank is less than 200 mesh.

[0051] (2) Treatment in the preheating stage: the resistance furnace is heated to 200 ℃ at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com