Method and device for identifying working condition of five-knuckle arm crane with wire ropes

A technology for working condition identification and cranes, which is applied to cranes, transportation and packaging, load suspension components, etc., can solve problems such as calling wrong performance curves, affecting lifting performance, and incomplete matching of performance curves, so as to improve lifting performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

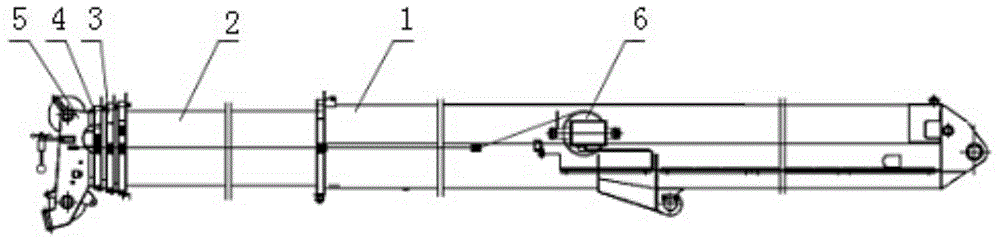

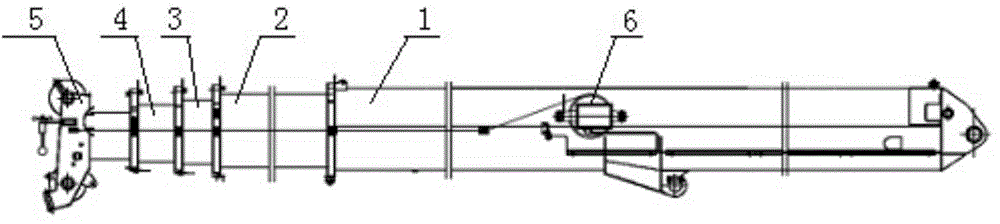

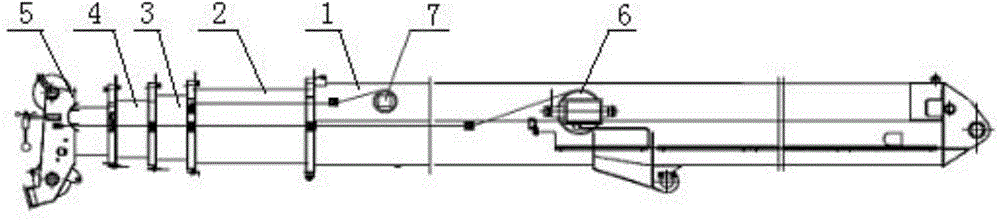

[0025] Such as image 3 with Figure 4 As shown, a method for identifying working conditions of a five-section jib rope row crane. The five-section jib rope row crane includes a crane upper arm, a telescopic cylinder, and a moment limiter system. The telescopic cylinder includes a primary telescopic cylinder and a secondary telescopic cylinder. The boom on the crane includes basic boom 1, two-section boom 2, three-section boom 3, four-section boom 4 and five-section boom 5, the first-stage telescopic oil cylinder drives the second-section boom 2 to expand and contract, and the second-stage telescopic oil cylinder drives the three-section boom 3, The four-section boom 4 and the five-section boom 5 expand and contract synchronously, and the moment limiter system includes a moment limiter host and a length angle sensor 6 installed on the basic boom 1 for measuring the extensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com