Micro-sprinkling belt spreading and rolling dual-purpose machine

A micro-spray belt and dual-purpose technology, which is applied in the field of water-saving irrigation auxiliary machinery, can solve the problems of deflection of the micro-spray belt, low labor and production efficiency, time-consuming, etc. good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0026] This specific embodiment is only an explanation of the present invention, not a limitation of the present invention. After reading this specification, those skilled in the art can make modifications to this embodiment without creative contribution as required, but as long as they are within the rights of the present invention All claims are protected by patent law.

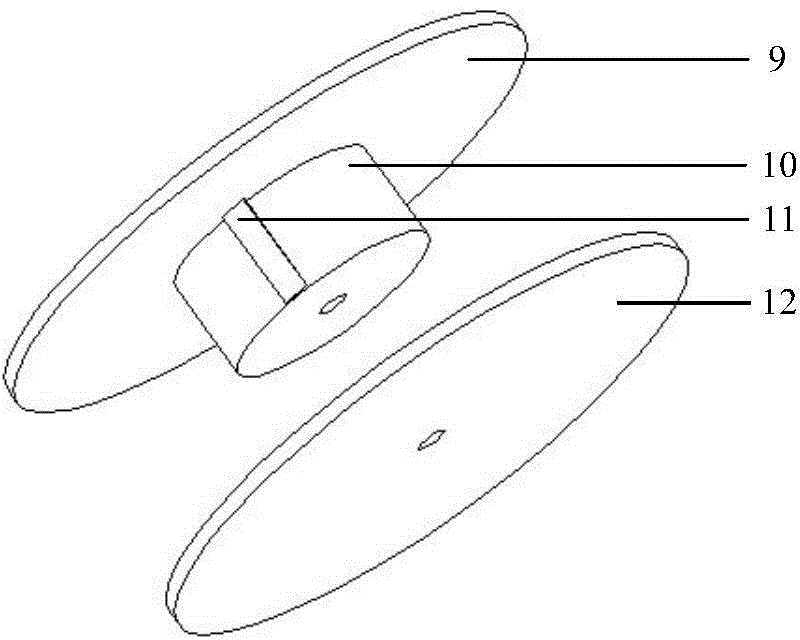

[0027] Examples see attached figure 1 , a dual-purpose machine for laying and winding micro-spray tape, including a frame, a steering handle, a winding wheel, a crawler wheel, a pressing wheel, a scraper, a transmission device and a guide wheel; the track wheel, the pressing wheel, the winding wheel and The width of the guide wheel can be determined according to the width of the micro-spray belt. The width of the track wheel, pressing wheel, take-up wheel and guide wheel is the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com