Automatic feed-type feeding mechanism

A feeding mechanism and automatic feeding technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems affecting the normal operation of the feeding mechanism, unable to meet the needs of production, and single-screw material blockage, etc., to avoid blockage and reduce labor. Strength, the effect of increasing the amount of feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

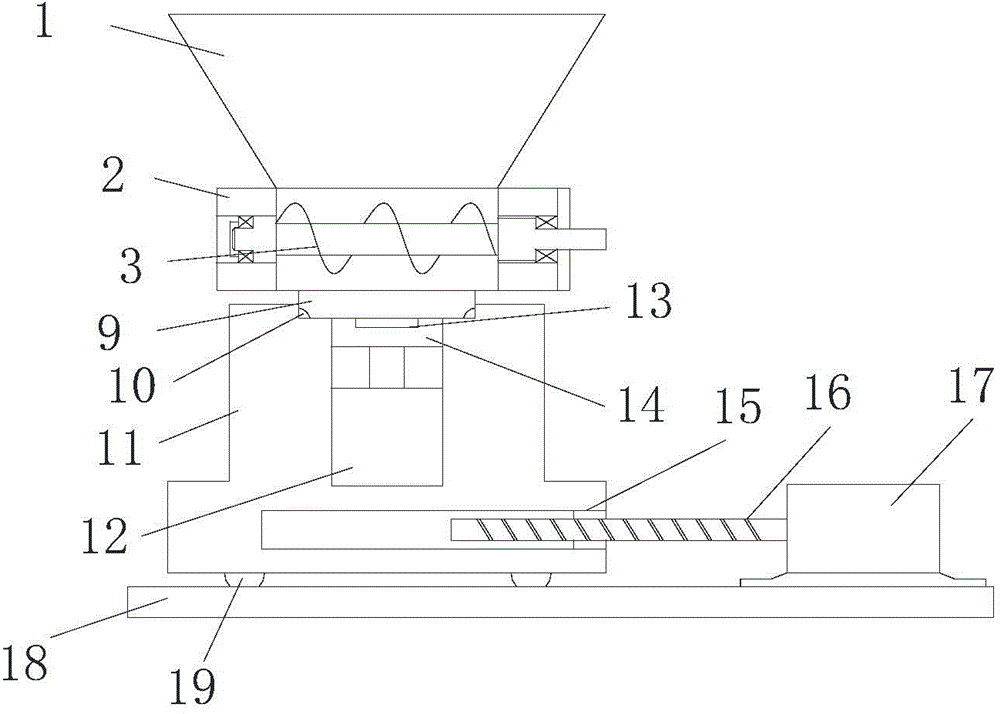

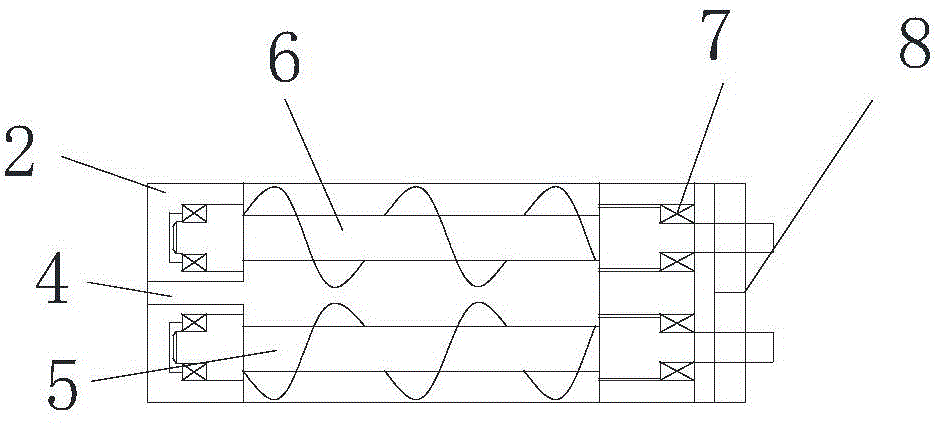

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] Such as figure 1 and figure 2 The shown automatic feed feeding mechanism includes a feeding mechanism, and is characterized in that: a base 11 is provided below the feeding mechanism, a guide hole is provided on the side of the bottom of the base 11, and a nut 15 is provided at the end of the guide hole. , the ground is provided with guide rail 18, and base 11 bottom is provided with the guide wheel 19 that cooperates with guide rail 18, and guide rail 18 is provided with driving motor 17, and driving motor 17 is connected with lead screw 16, and lead screw 16 is connected with nut 15.

[0020] Furthermore, an angle adjustment mechanism is arranged between the feeding mechanism and the base, and the angle adjustment mechanism includes a base 11 which acts as a fixed support. The middle part of the base 11 is provided with a mounting hole, and a driving cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com