High-speed feeding machine

A high-speed, feeder technology, applied in the field of toothbrush production and toothbrush hair planting production, can solve the problems of less toothbrush handles, poor waiting time, lower production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

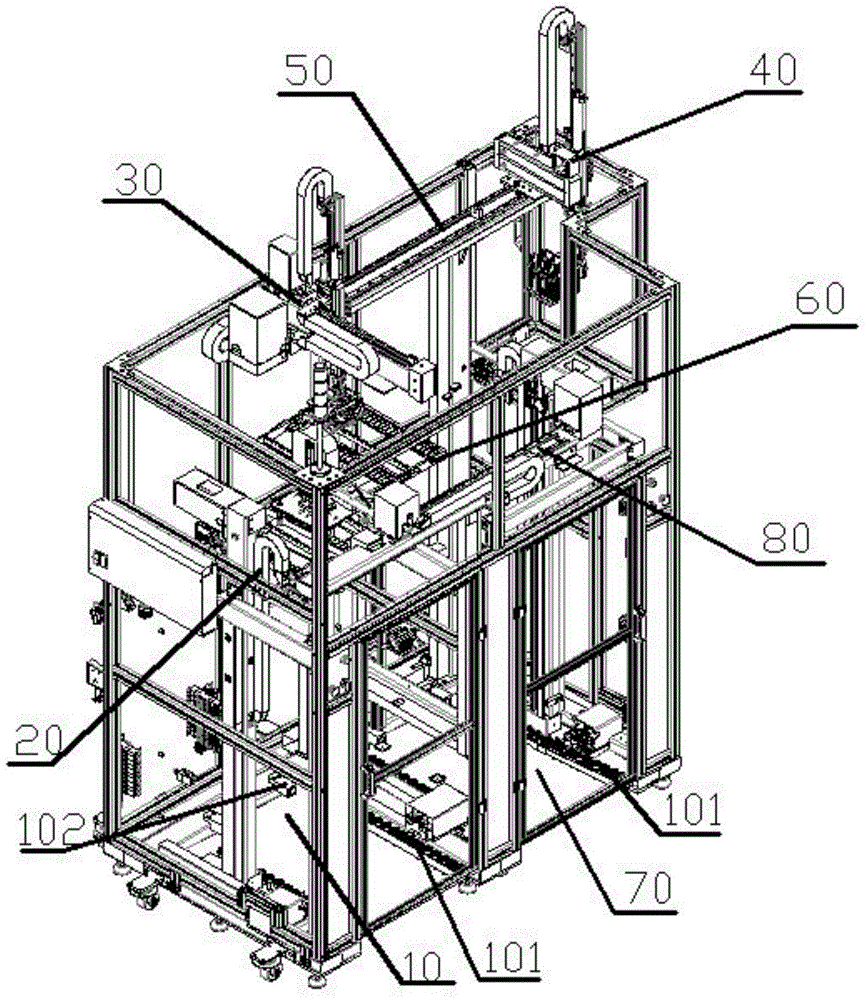

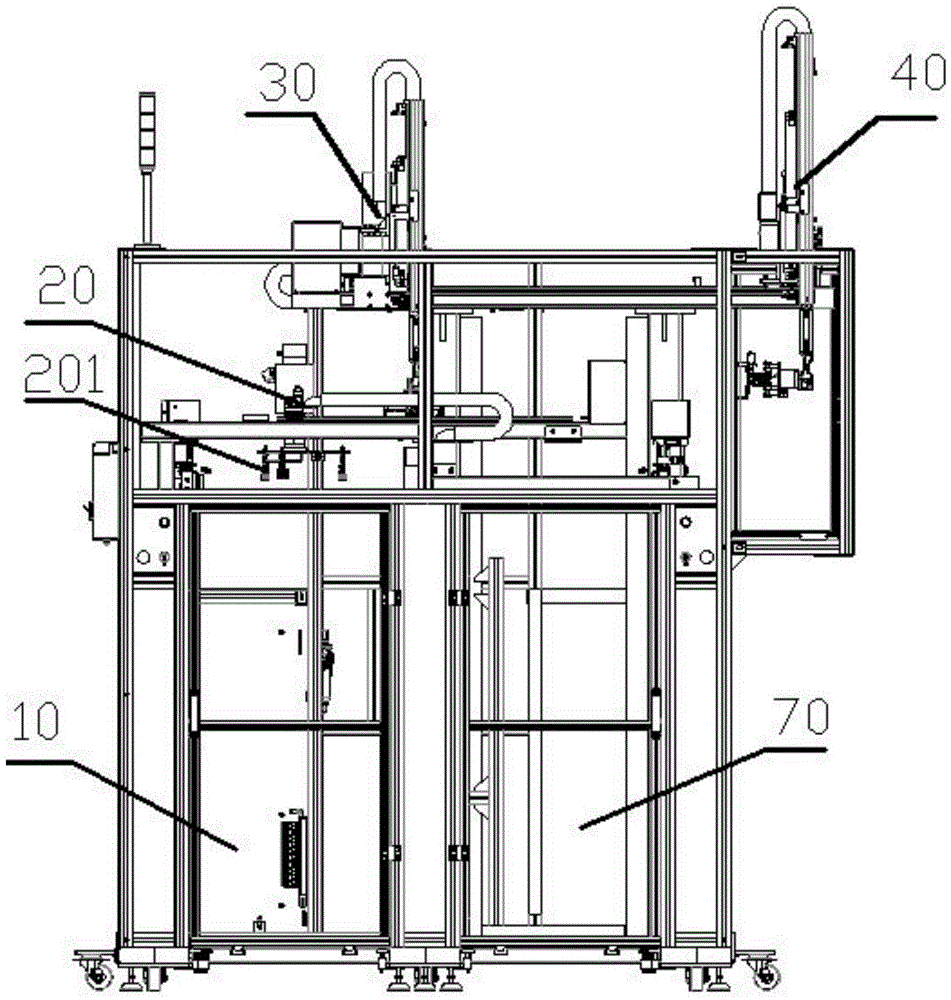

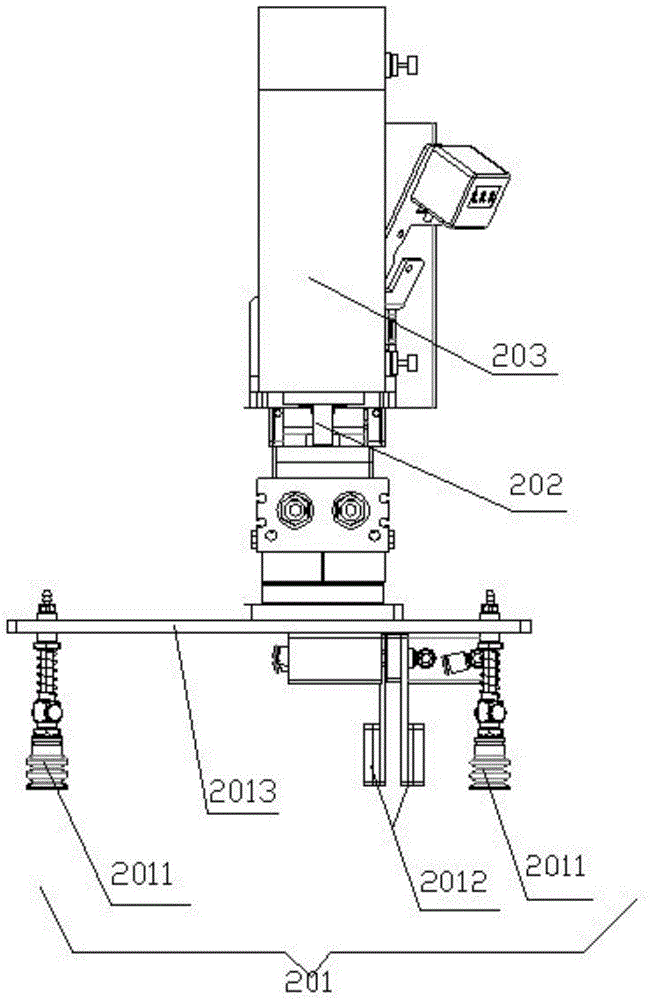

[0028] Such as Figure 1-2 As shown in , this embodiment discloses a high-speed feeding machine, which includes in sequence according to the stations: a feeding bin 10, a tray transfer mechanism 20, a high-speed retrieving robot 30, a high-speed shifting mechanism 50, and a feeding robot 40, and the tray recovery bin 70.

[0029] Specifically, the spatial structure of the above-mentioned parts is as follows: the above-mentioned feeding bin 10 and the pallet recovery bin 70 are arranged at the bottom position of the high-speed feeding machine, and there is enough space for the feeding trolley to enter; the above-mentioned pallet transfer mechanism 20, The high-speed reclaiming manipulator 30, the high-speed shifting mechanism 50 and the feeding manipulator 40 are arranged on the upper layer of the above-mentioned high-speed feeding machine.

[0030] Such as figure 1 As shown in , a section of guide rail 80 is provided above the space of the above-mentioned feeding bin and pal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com