Automatic material delivery mechanism of welding electrode packaging machine

An automatic feeding and packaging machine technology, applied in the direction of packaging, transportation and packaging, packaging item types, etc., can solve problems such as material jams or accumulation, error-prone production process safety, and reduce sealing film efficiency, so as to improve production quality, High degree of automation, guaranteed standard effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

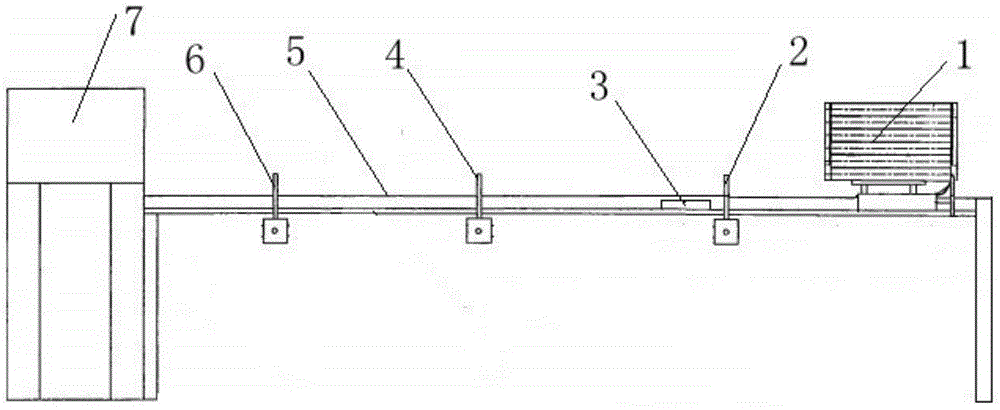

[0014] like figure 1 As shown, an automatic feeding mechanism of a welding rod packaging machine in the present invention includes a frame 5, a welding rod hopper 1, a cylinder 2, a weighing device 3, a shaper 4, a detection device 6, a film sealing machine 7, a welding rod hopper 1, and a cylinder 2 , a weighing device 3, a shaper 4, a detection device 6, and a film sealing machine 7 are arranged on the frame 5 from right to left in sequence. Frame 5 is provided with conveying trough, and described conveying trough comprises conveying chain, push rod, and conveying chain is installed under described conveying trough, and described conveying chain is equipped with described push rod. The push rods are equidistantly arranged on the conveying chain. The detection device 6 is an infrared detector.

[0015] The working process of this example: the welding rod is placed in the welding rod hopper 1. During work, the welding rod hopper 1 places the welding rod on the conveying trou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com