Automatic stamping machine

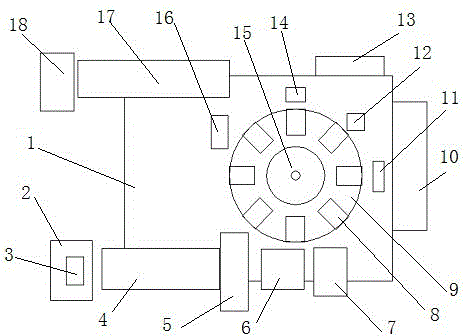

A technology of automatic stamping machine and rack, applied in printing, stamping and other directions, can solve the problems of inability to achieve automatic stamping, uncertain size and style and stamping position, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

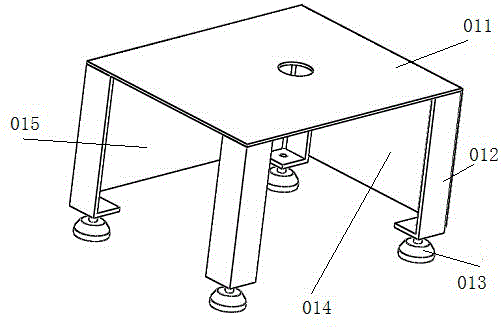

[0055] In order to further illustrate the technical scheme of the present invention, now in conjunction with accompanying drawing, further illustrate the specific embodiment of the present invention; Take the graduation certificate of width 150 millimeters, length 180 millimeters as example in this example.

[0056] Such as figure 2 , select a steel plate with a thickness of 20 mm, a width of 1200 mm, and a length of 1500 mm as the work surface 011, and process the mounting holes for the turntable system 9 and the transmission system 15 on it; select an equilateral angle steel with a side length of 120 mm and a thickness of 8 mm 600mm is used as machine leg 012, and steel plates with a thickness of 15mm are welded at both ends as baffles at both ends, and mounting holes are processed on the baffles; commercially available machine tool adjustable shims with a diameter of 200mm are used as height adjustment For installation 013, a steel plate with a thickness of 3 mm, a length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com