Dust and chip removing device for paperboard

An equipment and cardboard technology, applied in the field of cardboard dust removal equipment, can solve the problems of inability to eliminate static electricity, difficult to remove dust dust, etc., and achieve the effect of maintaining cleanliness, eliminating static electricity, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

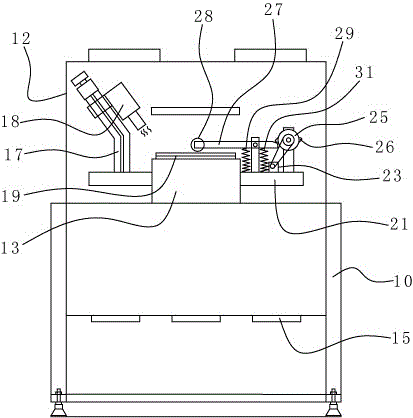

[0016] Such as figure 1 As shown, a cardboard dust removal equipment of the present invention comprises a frame 10, a dust removal box 12 fixedly installed on the frame 10, a material delivery rack 21 passing through the dust removal box 12 and installed on the frame 10, The conveyer belt 13 that is installed on described material delivery rack 21, the inclined vertical support 17 that is fixedly installed on material delivery rack 21, the plasma heat blower 18 that is installed on the oblique setting of described vertical support 17 by sleeve clip, is located at dust removal box 12 The air outlet 15 of the box wall, the air outlet of the plasma blower 18 is obliquely towards the conveyor belt 13. The cardboard dust removal equipment is equipped with a dust removal box 12 to form a relatively sealed dust removal space, and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com