Special cleaning equipment for tanks

A technology for equipment and tanks, applied in the field of special equipment, can solve the problems of complex and bulky structure, low cleaning efficiency, high labor intensity, etc., and achieve the effects of good cleaning effect, high operation efficiency and safety protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

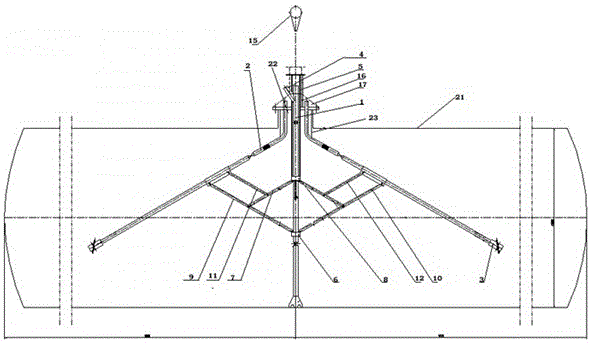

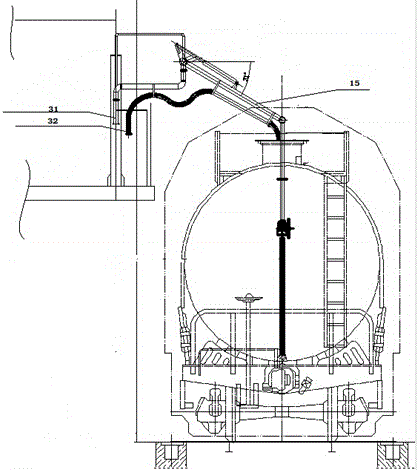

[0024] Such as figure 1 As shown, a special cleaning equipment dedicated to tanks, the tank is composed of a tank body 21, a manhole 22, and a baffle 23. The special cleaning equipment used for this tank includes a hollow middle discharge pipe 1 and a hollow water delivery pipe 2. The top end of the water delivery pipe 2 is a hose structure, and the bottom end of the water delivery pipe 2 is fixedly equipped with a tank washer 3 , the bottom end of the middle row pipe 1 is provided with a bottom hole, preferably, in this embodiment, a suction branch pipe 4 is also arranged at the side hole, and a lifting rod 5 is provided on the outer sleeve of the middle row pipe, and Corresponding to the lifting rod limit ferrule 6 arranged on the middle row pipe 1, two connecting rods are symmetrically fixed on the bottom end of the lifting rod 5, which are respectively the first connecting rod 7 and the second connecting rod 8. Two connecting rods are fixed on the end surface, which are r...

Embodiment 2

[0037] On the basis of Embodiment 1, we further disclose that an exhaust gas collection cover 17 is arranged on the upper part of the manhole, and the gas collected in the exhaust gas collection cover is directly introduced into the exhaust gas treatment device through the air guide pipe for centralized treatment.

[0038] Of course, the gas can also be left untreated according to the methods in the prior art, but since the amount of waste gas produced in the cleaning itself is relatively large, the use of a waste gas collection cover is more in line with the needs of environmental protection.

[0039] For different working conditions of the storage tank, this equipment can use "one set" mechanism, or "three sets" mechanism, or "four sets" mechanism to realize the operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com