Mordenite-Beta molecular sieve-Y molecular sieve composite material and synthesis method

A mordenite and composite material technology, applied in molecular sieve catalysts, chemical instruments and methods, catalyst carriers, etc., can solve the problems of affecting the catalytic performance of synthetic products, unfavorably forming composite pores, and difficult to control the ratio, and reduce electrostatic repulsion. The effect of acid property optimization and pore channel optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

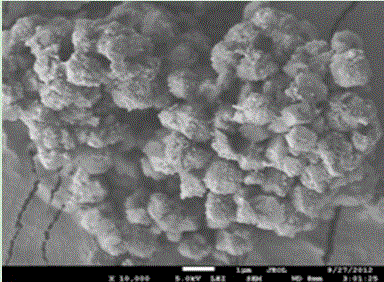

[0036]Preparation of nano-beta molecular sieve: Dissolve 0.5g sodium hydroxide and 0.9 g sodium aluminate in 60mL 25% TEAOH, add 15g white carbon black after the dissolution is complete, stir for 60min, put it into a closed reaction kettle, and put it in an oven Crystallization at 140°C for 30h. Then the obtained product was washed 4 times with distilled water to neutrality, and then dried at 120° C. for 12 hours to obtain the desired nano Beta molecular sieve of the present invention.

Embodiment 2

[0038] Preparation of nano-mordenite: Dissolve 0.35g of sodium hydroxide and 1.5g of sodium aluminate in 50mL of 25% TEAOH, add 15g of white carbon black after the dissolution is complete, stir for 60min, put it into a closed reaction kettle, and put it in an oven Crystallization at 170°C for 25h. Then the obtained product was washed with distilled water for 4 times to neutrality, and then dried at 120° C. for 12 hours to obtain the desired nanometer mordenite of the present invention.

Embodiment 3

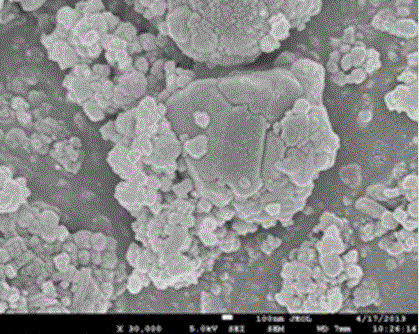

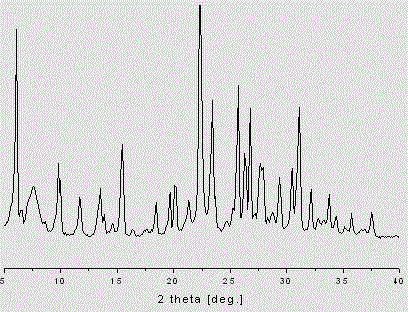

[0040] (1) Take 1g of the nano-beta zeolite prepared in Example 1, 1g of the nano-MOR prepared in Example 2, and 10g of Y-type molecular sieve into 200 mL of hydrochloric acid solution with a pH of 5, then add 1.1 g of NaCl, stir for 30min, and then Place in an ultrasonic cleaner for 5 hours. Then the obtained product was washed 4 times with distilled water to neutrality, then dried at 120°C for 12 hours, and finally calcined at 500°C for 5 hours to obtain a zeolite mixture.

[0041] (2) Dissolve 0.25g of sodium hydroxide in 30mL of 25% TEAOH and stir for 30min. Then add 0.5g of sodium aluminate and stir for 30 min. Add 7g of white carbon black slowly and stir for 30 min. Add 5 g of the zeolite mixture prepared in step (1) and stir for 30 min. The reactant mixture was then placed in an oven and dried at 100 °C until the water evaporated completely. Then place the obtained reactant dry gel on the upper part of the reactor, and place 10 mL of water at the bottom of the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com