Manufacturing method of hanging basket in extraction kettle and hanging basket

A production method and extraction kettle technology, which are applied in solid solvent extraction and other directions, can solve problems such as unsatisfactory material extraction effect, and achieve the effects of avoiding channeling phenomenon, improving extraction effect and efficiency, and avoiding loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

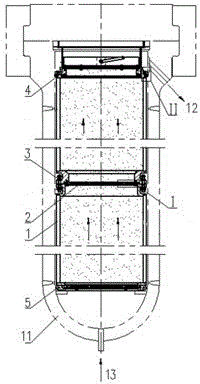

[0023] The present invention re-distributes the supercritical carbon dioxide fluid in the extraction kettle 11 multiple times to prevent the supercritical carbon dioxide fluid from forming a column flow or channel flow, and effectively improves the flow direction of the supercritical fluid in the extraction kettle, so that the extraction in the hanging basket The material is in full contact with the supercritical fluid, which greatly improves the efficiency and effect of supercritical extraction.

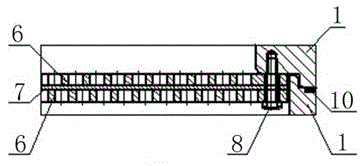

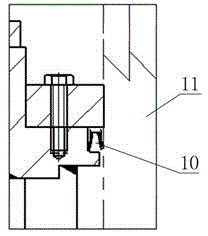

[0024] In specific implementation, such as figure 1 As shown, the hanging basket is made into a multi-section cylinder connection structure, and a distributor is installed between the lower end and the upper end of the hanging basket and each cylinder structure. The airflow enters the lower section of the hanging basket from the air inlet 13 of the extraction kettle, and the airflow When passing through the distributor 2, the distributor 2 re-distributes the airflow evenly, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com