Preparation method for microbial garbage deodorizer

A technology for microorganisms and deodorants is applied in the field of preparation of garbage microbial deodorants, which can solve the problems of ecological environment impact, air pollution, harm to sanitation workers, etc., and achieve the effects of inhibiting physiological activity, good environmental protection performance and environmental improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

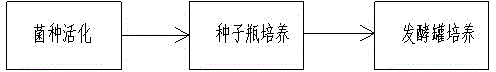

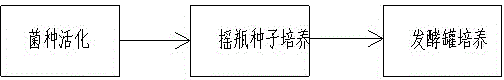

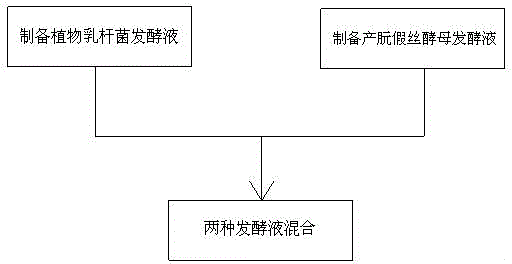

[0029] see figure 1 , figure 2 , image 3 The preparation method of shown rubbish microorganism deodorant, its step is as follows:

[0030] (1) Prepare Lactobacillus plantarum fermentation liquid;

[0031] (2) preparing Candida utilis fermentation broth;

[0032] (3) Fully mix the Lactobacillus plantarum fermentation broth prepared in step (1) and step (2) and the Candida utilis fermentation broth in a volume ratio of 1.5-2.0:1.

[0033] The preparation steps of the plantarum lactobacillus fermented liquid are as follows:

[0034] a1, strain activation, is to place Lactobacillus plantarum in the MRS medium and obtain activated fresh strain 1 through the activation of the slant strain; the MRS medium is the lactic acid bacteria fermentation medium;

[0035] a2. Seed bottle cultivation is to inoculate the seed liquid culture medium in the seed bottle with the fresh strains activated in step a1, and after cultivating at a constant temperature of 37°C for 28 ...

Embodiment 1

[0045] 1. Preparation of Lactobacillus plantarum fermentation product

[0046]Activation of slant strains: take the refrigerator to store the slant strains of plant lactic acid bacteria, inoculate them into fresh test tube MRS medium by aseptic operation, cultivate them on the slant, and cultivate them at a constant temperature of 37°C overnight to make fresh test tube slant strains. The MRS medium: by volume, peptone, 1%; beef extract, 1%; yeast extract, 0.5%; diammonium hydrogen citrate, 0.2%; glucose, 2%; Tween 80, 0.1%; sodium acetate , 0.5%; dipotassium hydrogen phosphate, 0.2%; magnesium sulfate, 0.058%; manganese sulfate, 0.025%; agar, 1.5% to 2.0%; the rest is water; pH 6.2 to 6.6.

[0047] Seed bottle culture: Take one ring of activated fresh test tube slant bacteria, inoculate it into the seed liquid medium in the seed bottle, the filling volume is 250 mL / 500 mL, after 28 hours of constant temperature cultivation at 37°C, stop the cultivation, and make the inoculum ...

Embodiment 2

[0057] 1. Preparation of Lactobacillus plantarum fermentation product

[0058] Activation of slant strains: take the refrigerator to store the slant strains of plant lactic acid bacteria, inoculate them into fresh test tube MRS medium by aseptic operation, cultivate them on the slant, and cultivate them at a constant temperature of 37°C overnight to make fresh test tube slant strains. The MRS medium: peptone by volume, 1%; beef extract, 1%; yeast extract, 0.5%; diammonium hydrogen citrate, 0.2%; glucose, 2%; Tween 80, 0.1%; sodium acetate, 0.5%; dipotassium hydrogen phosphate, 0.2%; magnesium sulfate, 0.058%; manganese sulfate, 0.025%; agar, 1.5% to 2.0%; the rest is water; pH 6.2 to 6.6.

[0059] Seed bottle culture: take one ring of activated fresh test tube slant bacteria, inoculate it into the liquid medium in the seed bottle, the filling volume is 250 mL / 500 mL, after 28 hours of constant temperature cultivation at 37°C, stop the cultivation, and make the inoculum; The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com