Semi-fermented low-salt fish leisure food and production method thereof

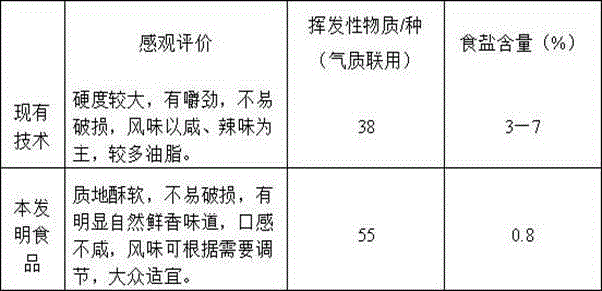

A snack food and semi-fermentation technology, which is applied in food preparation, food science, application, etc., can solve the problems of difficult to guarantee the quality stability and safety of fermented products, limit the consumption of fermented fish products, and long fermentation cycle, etc., and achieve improvement The texture of fish meat, the solution to the long production cycle, the effect of saving production time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Choose fresh sea fish, wash and cut into pieces, and cut the fish pieces into about 2×3 cm. The seasoning is added in two times. The seasoning is mainly conventional raw materials such as shredded ginger, cooking wine and spices, and the amount added is 1-5 grams per 100 grams of fish. Knead for 5 minutes each time. Let stand at 4°C for 4 hours.

[0024] (2) Hansenula and Aspergillus oryzae were cultured at a ratio of 1:1 at 25°C until the cell concentration reached 10 5 FU / mL. Adjust the fermenter to 15°C, inoculate the cultured strains into the fish block pretreated in step 1 and the 30% cornstarch mixture by weight of the fish block, and let stand for 6 hours.

[0025] (3) Put the material fermented for the first time into the chain drying box, and control the drying time of the fish pieces in the drying box to 45 minutes. The inside of the drying box is divided into three areas, the temperature of the first area is 50°C, The temperature in the second zone is...

Embodiment 2

[0028] (1) Choose fresh sea fish, wash and cut into pieces. Hansenula and Aspergillus oryzae were cultured at a ratio of 1:1 at 25°C until the cell concentration reached 10 6 FU / mL. Adjust the fermenter to 20°C, inoculate the bacteria into the fish block and 10% cornstarch mixture, and let it stand for 6 hours.

[0029] (2) Put the material fermented for the first time into the chain drying box, and control the drying time of the fish pieces in the drying box to 60 minutes. The inside of the drying box is divided into three areas, the temperature of the first area is 40°C, The temperature in the second zone is 120°C, the temperature in the third zone is 60°C, and then cooled to normal temperature. The drying time in each zone is the same, and the total time is adjusted by controlling the conveying speed. Through the above-mentioned variable temperature drying process, the water content of the fish pieces is controlled at 16wt%.

[0030] (3) Put the dried fish pieces in the ...

Embodiment 3

[0032] (1) Choose fresh sea fish, wash and cut into pieces. Add the seasoning in two batches, kneading for 10 minutes each time. Let stand at 4°C for 8 hours. Hansenula and Aspergillus oryzae were cultured at a ratio of 1:1 at 25°C until the cell concentration reached 10 7 FU / mL. Adjust the fermenter to 25°C, inoculate the bacteria into the fish block and 20% cornstarch mixture, and let it stand for 8 hours.

[0033] (2) Put the material fermented for the first time into the chain drying box, and control the drying time of the fish pieces in the drying box to 30 minutes. The inside of the drying box is divided into three areas, the temperature of the first area is 60°C, The temperature in the second zone is 105°C, the temperature in the third zone is 50°C, and then cooled to normal temperature. The drying time in each zone is the same, and the total time is adjusted by controlling the conveying speed. Through above-mentioned variable temperature drying process, the water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com